What is a diverter in a mixer?

Any mixer is a complex mechanism that consists of various elements. One of them is a diverter. Let's take a closer look at it, because not everyone knows what this element is intended for.

The content of the article

What is called a divertor in a mixer?

A diverter is a special unit that redirects the flow of water to the desired pipe: to a shower spout or mixer. Switching the flow into the watering can and hose depends on the operation of this element.

The switch mechanism includes a special crank. Thanks to him, the barrel with the valve moves. The mechanism also uses a rod and rubber gaskets. If you change its position, one or the other pipe opens.

Unfortunately, it is the diverter that is the “weakest link” in the mixer, and it is the one that first becomes unusable.

There can be several reasons for breakdowns:

- wear of gaskets;

- corrosion.

The latter occurs due to insufficient fit of the valve, which is why water begins to seep into both pipes at once. For this reason, the mixer begins to leak. However, any diverter element can be easily replaced. But we must not forget about the service life of the mixer. If you have been using it for a long time, then sometimes it is more advisable to change it completely than to carry out repair work.

Types of mechanism

There are several varieties. Let's take a closer look at each of them.

Button

A classic version of a diverter in a mixer, which is popular among consumers. A push-button mechanism is installed when there is a high power pressure in the pipeline and it is impossible to automatically lock the switch. To change the direction of flow, you need to pull the lever up, or vice versa, lower it down. For this reason, the second name for the push-button mechanism is the exhaust mechanism. Available in manual and mechanical versions.

Lever or flag

Also, such a diverter can be rotary. It has a simple design. To change the direction of flow, just turn the handle. The mechanism is installed when the mixer is equipped with two handles.

Spool

Most often, the spool mechanism is installed on a two-valve mixer. It is distinguished by its simplicity, which allows you to replace or repair the mechanism without the involvement of specialists.

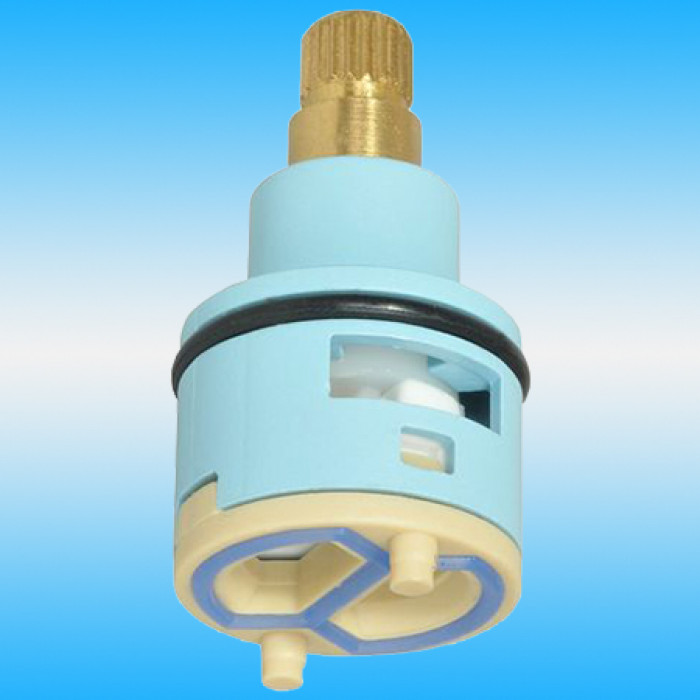

Cartridge

Has only one lever. It is responsible for the pressure and direction of flow. The disadvantage of the product is that such a mechanism cannot be repaired, so if it breaks, it is simply replaced with a new one.

Eccentric

The second name for such a diverter is ball. It can be activated by turning the handle, which activates the rod. This element allows you to open or close the desired pipe.

It is distinguished by its simplicity and ease of repair. The most common failure is failure of the rubber gasket. This can be called the main advantage of the mechanism. However, if a serious problem arises, then to carry out repair work you need to unwind the entire mechanism, which is very time-consuming and difficult.

Suberic

It is not popular because it is not entirely convenient to use. Although the advantage of this type of diverter is that it is easy to repair.

According to their functionality, diverters are of 2 types:

- two-position;

- three-position.

The first is distinguished by its accessibility, due to which it is more in demand. The second option is more complicated. It is most often installed in the kitchen.

If we consider diverters by installation method, they also differ from each other. They can be:

- built-in;

- separate or independent models.

What is a diverter made of?

This mechanism is made from various alloys or metals. The most popular of them are aluminum and brass, silumin. Ceramic models are also sometimes found.

Silumin has one huge disadvantage - it quickly corrodes. For this reason, it has a short service life. The alloy of aluminum and brass is also not particularly durable, so it is inexpensive.

The fact is that during the production of such a product lead is added, and its wear resistance and strength leave much to be desired.

The corrosion process on mechanisms made of silumin or metal alloys occurs due to changes in water temperature.

If we consider products made from pure brass or aluminum, then these are some of the most durable and high-quality diverters. The disadvantage of such products is that hard water can form limescale. A push-button mechanism will last longer than a lever-type product.

Ceramic diverters are made of metal that is coated with chrome. The plates of the locking system are made from ceramics. This material can withstand mechanical stress and therefore has a very long service life.

For some models, manufacturers provide a warranty of more than 45 years. Also, the ceramic diverter can withstand water hammer and any other loads that can easily destroy silumin or alloy. For this reason, ceramic products are of high quality, for which you will have to pay extra.

To extend the service life of the ceramic diverter, it is necessary to carry out preventive cleaning of all mechanisms. This will help avoid plaque formation and rapid failure.

... “The alloy of aluminum and brass is also not particularly durable, so it is inexpensive.

The fact is that during the production of such a product lead is added, and its wear resistance and strength leave much to be desired...

... If we consider products made from pure brass or aluminum, then these are some of the most durable and high-quality diverters.”

Alloy of aluminum and brass? If we talk about aluminum alloy, then most likely we are talking about silumin, and its disadvantages were mentioned above. An alloy of brass?..)) It is itself an alloy))))

Products made of PURE brass and aluminum?... Interesting)), but I didn’t find brass in the periodic table of Mendeleev). And the diverters made of PURE aluminum (!) are simply fantastic!!!! 40 years of work in metallurgical production... apparently that’s not what I was taught))

Products from