Why should a ball valve only be opened all the way?

To supply water in modern houses, various types of pipes are used, through which it enters the apartments of residents. And to regulate the pressure, special mixers and taps are used. Currently, ball valve models are often used. Keep in mind: it is best to use it only closed or open, but not halfway! Why? Let's figure it out.

The content of the article

Design and operating principle

To understand why this type has special requirements, you need to remember its design and basic operating principle.

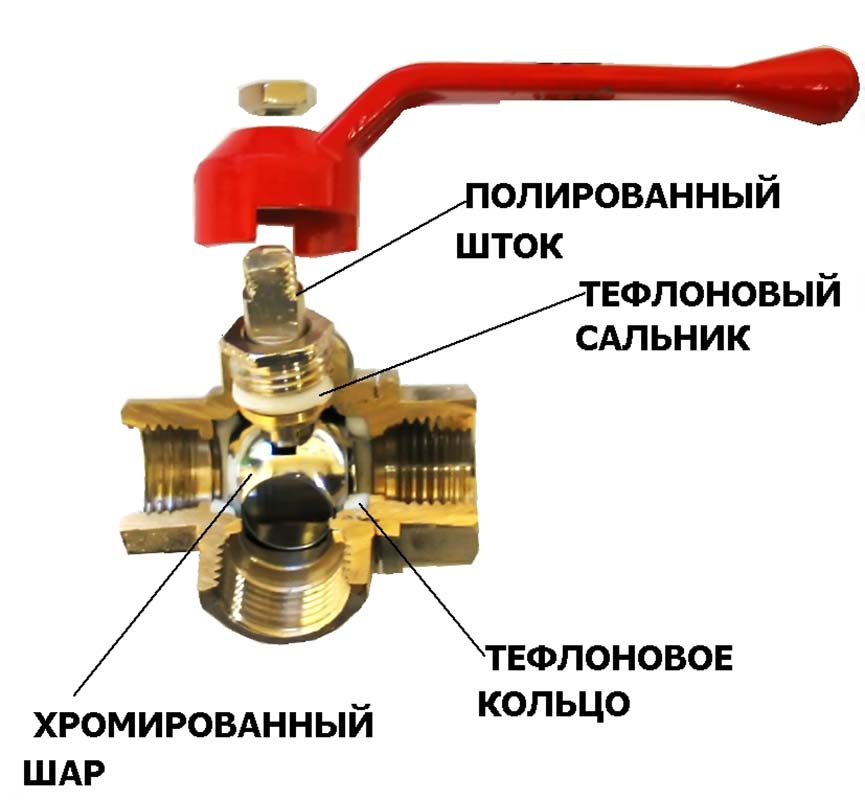

Device

In most cases, crane designs include fluoroplastic rings, intended for compaction of constituent elements. They are located between the hollow ball-shaped bolt and the main body.

PTFE rings are attached using a special threaded element that connects the components of the tap.

Gate has a small hole, which ensures a loose fit to the structure.

Principle of operation

When water enters under high pressure, the ball valve can move towards the fluoroplastic ring and press it. This principle of operation ensures the tightness of the structure and does not allow water to escape freely.

The ball valve is designed to operate in two positions.

Reference. Changing the position is achieved by turning the valve 90°.

At the same time, there are special restrictive marks around the circumference that prevent further passage of the shutter.

When closed element, water does not flow through the valve element. A in open position Laminar water movement is created that does not violate operating conditions.

What happens to a mechanism that is half open?

The only correct operation option is to operate the valve in the closed or open position. When the valve is opened, water flows freely along the hollow tube and comes out. However when the tap is opened halfway, changes occur in the mechanism.

Extra pressure

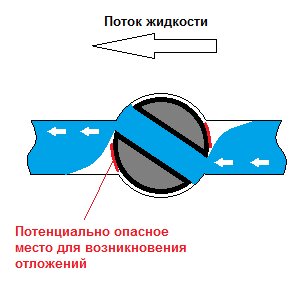

If the closure is incomplete, the water does not flow straight, but at an angle.

Important! The entry of liquid at an angle creates additional pressure on the valve. As a result, this can lead to deformation of the structure and failure of the mechanism.

If the tap is used for a long time in this position PTFE rings and fixing elements may be damaged. This may cause a leak.

Turbulent movement

When turning the shutter element not all the way turbulent movement of water occurs through the pipe. Such a flow creates excessive hydrodynamic pressure on all structural elements.

The middle position of the shutter does not allow regulating the water pressure, since it forms a turbulent rather than laminar flow. At the outlet, a mixed jet is formed, characterized by a large radius of liquid dispersion.

Additional corrosion

When water passes at an angle, areas appear where it does not pass. Heavy metal deposits accumulate in these places.

Important! Using a faucet that is half open results in additional corrosion and wear of the material.

Ultimately Improper closing of the shutter leads to structural failure.

Other ways to regulate water pressure

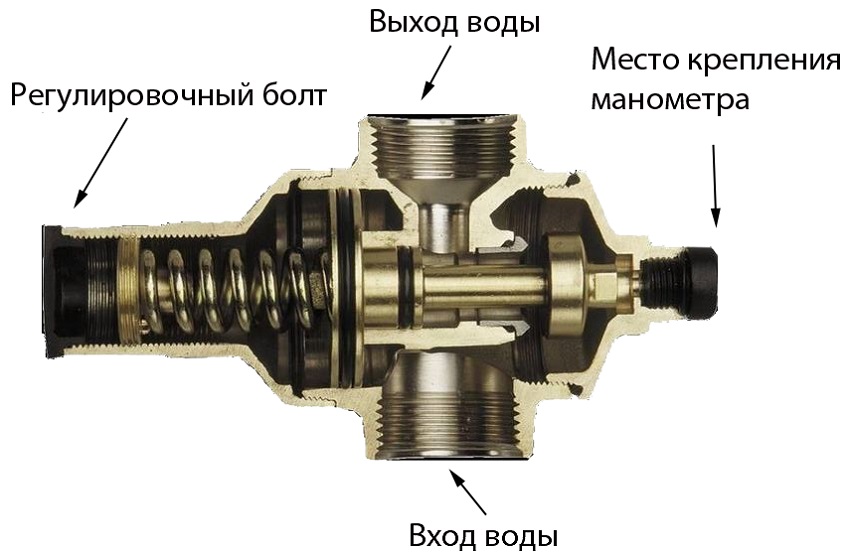

If you need to regulate the water pressure, you can use one of the following options.

The simplest way is complete change of mechanism. Initially, you will need to dismantle the ball valve. It is important to turn off the water! After which you should install a modern mixer model with the ability to regulate water supply.

A more complex option is to install an additional element that regulates the pressure and maximum pressure in the system. The complexity of the presented option is that elements are installed in the pipe after the ball valve.