Which is the best bathtub drain and overflow?

Safe use of the bathtub is ensured by the drain-overflow complex (another name is piping). Read about what this system is, selection rules, options, materials and connection methods in our material.

The content of the article

What kind of system is it - drain and overflow?

This is a single structure consisting of interconnected pipes. She serves to protect against water flowing over the edge of the bath during filling and ensures its quick reset after completion of the procedures.

We list the necessary parts of the device:

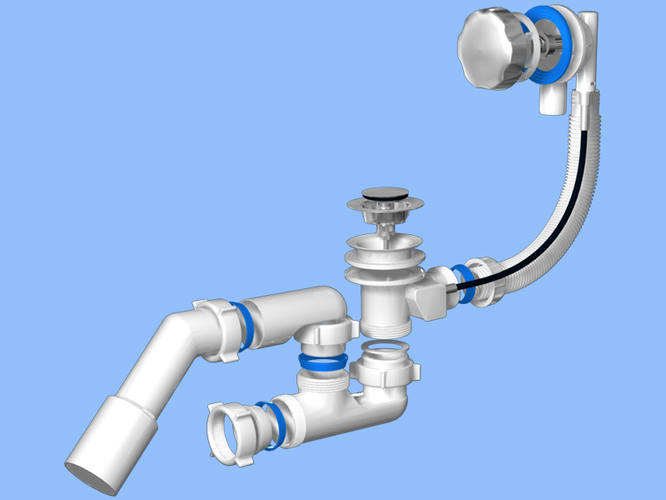

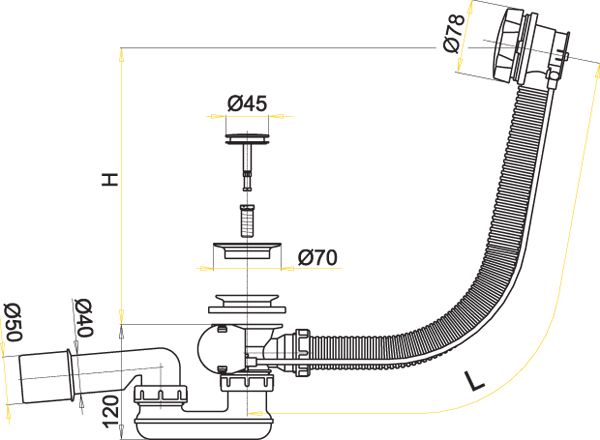

- Drain connector. Located at the bottom of the bathtub, it is a connection made of a chrome funnel that catches large contaminants and a piece of expanding pipe with a built-in nut. A steel screw holds the elements together, and a rubber seal protects against leaks. This part is used to collect and drain water.

- Overflow opening. It is located in the wall of the tank, has a similar design, and is connected via a side drainage system. It is used to control the liquid level in the bath.

- A siphon is an arc-shaped device that blocks odors from the sewer. It is connected to the overflow with a corrugated line (excess water flows in), the transition from it to the sewer passes through an additional pipe, which allows you to empty the bathtub.

How to choose? Options

The buyer first of all pays attention to the appearance of the product. However, it is necessary to take into account a number of nuances:

- Pay attention to the manufacturer, how well-known it is and whether it is popular, look at reviews of its products.

- Assess your financial capabilities. The classic version (plastic model) is more affordable, while the more expensive versions are semi-automatic and automatic.

- Make sure your bathtub is compatible with the new equipment; mismatched pipe diameters are connected using adapters.

- If additional capabilities are needed (for example, a siphon may have several connections through which various plumbing fixtures are connected), make sure they are available.

- A complete set of equipment, in addition to the system itself, contains the required number of connecting rings and gaskets.

- External elements through which water passes retain their design, strength and resistance to oxides if made from stainless steel.

Material

Industry uses three types of raw materials resistant to corrosion, hot liquids, alkaline, acidic agents:

- Ferrous metals are resistant to external factors and have a long service life; they were common in the last century, but are now giving way to modern materials.

- Plastic structures are distinguished by their low cost and versatility of size (suitable for non-standard bathtubs). Other advantages are ease of assembly, light weight and lack of deformation when in contact with water.

- Non-ferrous metals have the longest service life, increased strength, and attractive design. If the device is cleaned regularly, it can last for several decades.

The raw materials used must meet the following parameters:

- ferrous metals have no defects (dents, cracks, etc.);

- high-quality plastic is determined by its dense shell;

- non-ferrous metal is characterized by a smooth surface that is free of damage.

Automation system

There are three types of devices in stores:

- classic harness;

- semi-automatic;

- machine.

The simplest and most affordable option does not involve moving parts. Liquid begins to accumulate after the plug is closed or goes down the drain when the plug is opened.

Semi-automatic

Made the bathing process easy and simple. This is a more complex device than a standard harness and contains the following elements:

control lever - ensures closing and opening of the plug;

control lever - ensures closing and opening of the plug;- shutter valve - depending on its position, liquid enters or leaves the tank;

- shut-off rod – regulates the position of the system.

The control unit can have different types (key, handle, rotary part, etc.). He activated by pressing or turning, then a cable is moved, which acts on the valve, facilitating its opening or closing.

On a note! The rod can be located both inside and outside the pipe (pipe). The first method is more difficult to repair, but will provide an attractive appearance to the model.

Product advantages:

- convenient to control the drain (no need to get your hands wet);

- stylish design of the structure (the overflow hole is hidden behind the control module).

The disadvantages are the complexity of assembly, due to which individual components (for example, a cable) can fail over time.

Automation

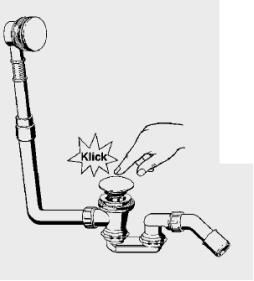

Such equipment consists of a key-valve. Management occurs in 2 steps:

After the first press of the button, the spring in the valve is activated, lowers it, thereby closing the drain hole. The built-in lock ensures that liquid is collected.

After the first press of the button, the spring in the valve is activated, lowers it, thereby closing the drain hole. The built-in lock ensures that liquid is collected.- Repeated exposure activates the release of water.

Advantages:

- It is convenient to switch modes with your foot;

- minimum dimensions of the device;

- the keys have a variety of designs;

- flooding is eliminated by filling the bathtub through the upper entrance (water stops flowing in case of excess).

The disadvantages of this option are the high cost, complexity of installation (professional skills are required) and replacement of the key, and relatively rapid wear of the spring.

Installation method

Installation methods are identical for all varieties, with one amendment: It is better to entrust automatic (preferably semi-automatic) devices to an experienced technician. This is necessary to maintain the product warranty.

Important! Read the instructions for the product and strictly follow the specified sequence of actions to avoid possible errors.

Operating procedure:

- if old equipment is installed, we dismantle it;

- remove dirt, rust, etc. from both sides of the bathtub, if necessary, clean the section of pipe leading to the sewer;

- we equip the connection to the drain hole and the adapter for drainage with nuts (threads facing the joint joint), put on conical gaskets (their narrow side is turned towards the joint) and connect them to the siphon;

- the mentioned parts are tightly fixed to the siphon with union nuts;

- Place a gasket on top of the drain part, in a special recess;

- install the drain connector, with its top part towards the bottom side of the tank, into the drain hole, taking into account the desired location of the pipe section connected to the overflow pipe;

- We seal the bathtub drain from above with a ring, then lay the grate and fix it with a screw (it is screwed into the nut inside the neck);

- the second side of the adapter is equipped with a nut, threaded outwards, and a conical gasket; it is connected to the sewer pipe with a corrugated liner (the latter is purchased separately);

- place the gasket in the upper part of the overflow pipe, inside the union nut, then connect it to the overflow connector;

- in an identical way, we combine the specified pipe with the drain pipe;

- We place the rubber gasket on the overflow part, which we press against the overflow of the container from the outside;

- We equip the overflow with a grille and secure it with a screw (screwed into the neck nut).

Important! We have provided a general installation diagram; in some cases there may be differences.

Manufacturer

The stores offer products from both domestic and foreign companies. We recommend choosing a product whose manufacturer has international quality certificates. List of reliable manufacturers:

- Geberit, a Swiss brand, produces plumbing systems at average market prices, in a wide range. Raw materials used: plastic, brass, copper, chrome steel. Swiss companies are known for the quality of their products, reliability and long service life.

- Kaiser uses bronze and chrome steel. Its systems are worth paying attention to in situations where a siphon of non-standard dimensions is needed (for deep bowls).

- Viega - products are characterized by a variety of designs and are affordable. Plastic, bronze, brass, and stainless steel are used in production.

- Hansgrohe manufactures structures based on polymer, steel, and combinations thereof.

- WasserKraft uses both white and black plastic, steel, bronze and a combination of raw materials.

- The Czech company Alcaplast produces simple and reliable devices, the largest supplier in Eastern Europe.

- The French company Jacob Delafon specializes in polymer sanitary ware and combinations with other materials. In our country, its products are in demand due to their quality, ease of installation and operation.

- The Russian manufacturer Triton produces products from plastic and mixed raw materials. The models are distinguished by an affordable price combined with fairly reliable characteristics.

Use our information, and choosing a drain-overflow system will not present any difficulty. There are only three modifications: manual, semi-automatic and automatic modes. By focusing on the best manufacturers, you will make a quality purchase that will last for many years. You can install a simple circuit yourself, but we recommend entrusting complex installations to specialists.