DIY shower cabin

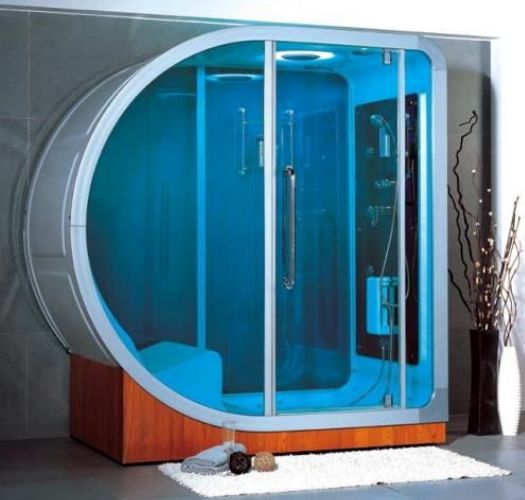

You don’t need to be Vanga to guess that today in most apartments the bathroom is equipped with classic bathtubs. And with a greater degree of probability, we can assume that many people walk around shower stalls and figure out in their minds how it would fit into the interior, how stylish and convenient it is, and... they pass by. The fact is that most people, to put it mildly, cannot afford high-quality, functional and stylish options.

Needless to say: hydromassage, built-in telephone, lighting and relaxing music cost a lot of money. Some may object that the purpose of a shower cabin is to help you take a shower and wash off the sweat and dust of a working day. All this is true, but... somehow I don’t want to use cheap options. It’s easier then to lie down in warm and pleasant water, you can even with a book in your already familiar bath. And what? That's all? Not really! You can always build a shower stall yourself. How? Let's see.

The content of the article

Examples of do-it-yourself shower cabins

Where to start when creating your own shower stall? Yes, it’s probably better to study the experience of those people who have already passed this stage and are now enjoying the fruits of their own efforts.

If we talk about a shower stall in a private house, then it can be placed anywhere. Or rather, where it fits. If you pay attention to the photographs, the booth is comfortably located in the space between the wall and the stove, in an ordinary kitchen. This creation of engineering does not have a steel tray; it is replaced by tiles, which are laid at a slight angle to the drainage drain.

The floor in the cabin is raised above the floor in the kitchen. In this case, this is a necessary measure so as not to dismantle the floor to install a drainage funnel. To prevent water from the cabin from getting into the kitchen, it was separated by a threshold with two degrees.

The craftsman needed bricks, tiles and moisture-resistant drywall to create his booth. Seamless plastic panels are installed on the ceiling. Even the kitchen stove looks harmonious with the shower cabin, as they are finished together in the same style.

Water is supplied using a pumping station from a well. There is a compact size water heater. All this made it possible to obtain a small shower cabin with cold and hot water.

A shower stall will look very good and unusual if you assemble it yourself from glass blocks. This material is no less durable than brick, but at the same time it looks very decorative. You can learn how to lay glass blocks very quickly, and you can make the most unusual shapes from it. If you look at the photo, you can see how stylish the glass block looks paired with tiles that look like natural stone.

On the floor of the cabin there is a concrete screed, on top of which there are porcelain tiles. The walls are also made of ceramic tiles.

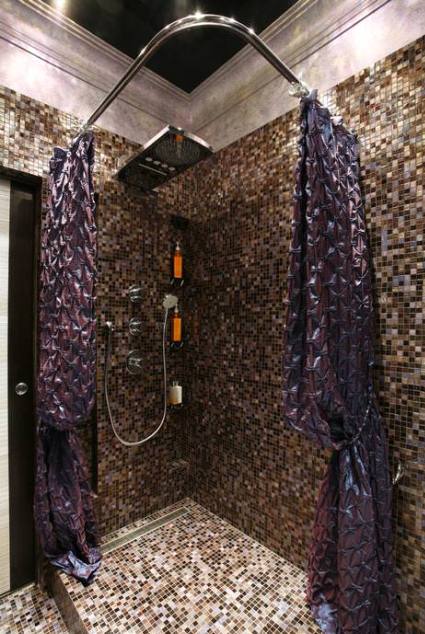

Not every person likes the option of replacing a transparent screen with a film curtain, but in this case it looks very good.

Mosaic cladding and fabric that does not get wet and is suspended on a chrome-plated arc. This whole composition looks like the work of a real designer.

When choosing a material to create your shower, you should pay attention to cellular polycarbonate. It is quite durable, not afraid of water and looks beautiful. Based on it, you will get nice transparent cabin walls and a door.

The edging for it is made on a base made of aluminum or plastic. The door itself can be hinged, or you can install a sliding one. This is easy to do if you attach the wheels from the cabinet to the bottom side of the polycarbonate and insert them into the guide.

Due to its flexibility, polycarbonate allows you to create a wide variety of shapes.

Plexiglas is no less popular for creating shower stalls. It is not as durable as polycarbonate, so it will have to be framed with stainless steel corners.

Based on glass, simple and airy homemade structures are obtained.

It is easy to combine with tiles.

A quite good cladding option is plastic lining. It can be easily and quickly combined into a single panel that is not afraid of moisture. It attaches to absolutely any surface.

The walls can be made from a homogeneous material, or they can be composed of different ones.

By using your imagination, you can create a cozy relaxation corner from durable plastic. As if in an oasis, you can not only take a bath here, but also relax under the streams of warm water and practice meditation.

It is quite easy and quick to make a cabin frame from plasterboard, then finish it with moisture-proof material and cover it with tiles. The design will be inexpensive and easy to install.

The right place for a shower stall

The main limitation that is imposed on the location for installing a shower stall is the size of the room and, naturally, the presence of communications for drainage and water supply.

First of all, before you start making your dream come true, you need to carry out preparatory work:

- Check the water supply and sewer system. Make sure there are no leaks or rusty areas. Evaluate the quality of connections and seals. If something is of poor quality, these elements should be updated.

- You definitely need to check the condition of the partitions: walls, ceiling and floor. Particular attention should be paid to the part of the floor in the place where you plan to install the booth. If necessary, level the floor and ensure good waterproofing.

Important! The shower stall is an open structure. It is difficult to protect fences from contact with water, and, accordingly, from the impact of water on the energy system. Make sure to replace all electrical appliances in the immediate vicinity of the booth with waterproof ones.

Calculation of dimensions and selection of materials

Once everything has been decided on the installation location of the cabin, you can begin to calculate the dimensions of the future structure. The main thing is that the cabin does not take up all the available space, but also does not lose functionality due to its small size.

According to the standard, the shower cabin measures 900 by 900 millimeters.If the pallet is low, then the height is 2000 millimeters, and if it is deep, then the height of the structure will be 200 millimeters higher.

Important! All sizes are relative values, because you will need to select them individually for a specific case. All family members should be comfortable using the design.

To construct the cabin, you can select materials that are available in a wide range on the market. Widely used:

- cellular polycarbonate;

- plastic panels;

- glass.

The most inexpensive way to attach these materials is aluminum profiles. To build a fence, it is quite possible to take moisture-resistant plasterboard, which then just needs to be tiled.

You can make a fencing based on glass blocks on a budget and beautifully.

Preparing for work: tools and materials

Any work should begin with the preparation of the necessary tools. Materials for work should also be selected based on the features of the future design. To summarize, you need the following:

- sewer pipes with bends and seals;

- waterproofing;

profile, fasteners, etc. To lay out the pallet, you can take bricks or expanded clay blocks. To fill the tray with cement mortar, you will need plastic to form a mold from it. If the fence is brick or block, you will need to prepare:

To lay out the pallet, you can take bricks or expanded clay blocks. To fill the tray with cement mortar, you will need plastic to form a mold from it. If the fence is brick or block, you will need to prepare:

- trowel with hammer;

- mixer for solution;

- building level.

For plastic pipes you will need:

- soldering iron;

- pipe knife;

- screwdriver

In addition, you need to have on hand:

- sealant gun;

- roulette;

- construction square.

It should be remembered that laying out the pallet is not enough. It also needs to be lined. As a rule, tiles are used for finishing.It may require adjustment in size, so you need to have a tile cutter or grinder with a stone wheel.

If a factory acrylic tray is installed, you will need screwdrivers and sealant.

Do-it-yourself shower cabin: stages of creation

It's time to get started with the creative process of creating the shower stall of your dreams. As mentioned above, you can make a pallet yourself, or you can purchase a ready-made one in a store. The second option is easier to install, so let's start with it.

We use waterproof plasterboard as a fencing material. Before you start, you need to stock up on the necessary building materials. You will need:

- sheet silicate glass;

- expanded clay concrete blocks;

- brick for laying sides;

- facing tiles;

- moisture-resistant tile adhesive;

- cement mortar;

- waterproof screed;

- waterproofing.

Naturally, you will need to purchase a drain and a siphon. The water must somehow get into the sewer system.

Installing the factory pan

To install the purchased pallet, you need to make a frame. It may take the form of a metal frame or be assembled from timber, which must be treated with a moisture-proofing compound.

The sequence of work will be as follows:

- We secure the frame to the pallet with metal pins. We attach one end to the frame supports, and the other to the holes on the edges of the pallet.

- We attach metal beams to the studs using nuts. After their position has been adjusted, they need to be locked.

- We install the pallet, adjust its height and inclination. It should have a slope towards the drain.

After this, we install a drain with a siphon, if they are not already installed at the factory. We treat the joints and joints with sealant.

Making your own pallet

Creating your own pallet has the advantage of allowing you to make a cabin of any size and shape. This is especially true for a small bathroom. We adhere to the following work plan:

- First of all, prepare the solution. The mixture must be diluted following the proportions specified by the manufacturer. It would be better to use a large bucket and a mixer. Instead of a mixer, a drill with a special attachment will do.

- We place the blocks on a prepared and waterproofed base. Between the blocks we lay communications and a ladder for draining water. To facilitate further maintenance, free space should be left between the blocks and communications.

- Along the edge we build sides from bricks laid on their sides. This will be the basis for the fence.

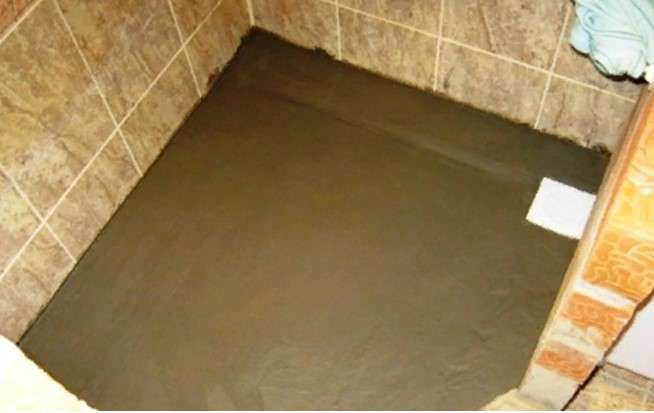

- The pallet is filled with waterproof screed. Filling layer, up to about five millimeters.

We are building a corner

We use brick as a material for building walls:

- We will apply mortar to the sides and lay bricks horizontally in a row on it - you need to lay it edgewise;

- In order for the masonry to be monolithic, proper dressing should be ensured - for this, the longitudinal seams lying in adjacent rows should be shifted by half of the brick;

- the corner is erected to a height of seven rows - the thickness of the seam should be twelve millimeters;

- The brick is attached to the wall using steel rods - the rods are laid in the seams between the bricks and driven into the main wall.

Important! To prevent water from the cabin from entering the external space, you need to lay out a curb.

Installing a fence

Once the corner is laid out to the desired level, you can begin to install the fence.For example, consider a silicate glass fence six millimeters thick:

- We attach a plastic corner profile to the walls of the corner and to its upper edge. Dowel plugs and impact screws will help securely fasten it.

- The glass in the profile is secured with sealant. To ensure safety, the edges of the glass that remain exposed are chamfered.

- A curtain will be installed as a booth door. It will be supported by a frame made of stainless pipe. The pipe will be secured to the wall with flanges.

As you can see, everything is quite simple. With due diligence, patience and dexterity, the task can be completed quite easily and quickly. However, we have considered the simplest options; if the task is to create a shower stall of a more complex shape and with additional functions, this will require more time and work experience. In any case, if you do nothing, then nothing will happen!