Toilet cistern design

The toilet is an indispensable attribute of any modern toilet. Its most complex and important part is the tank. Read on to learn about the structure of this element, its functioning, its types and troubleshooting methods.

The content of the article

Description of the cistern with a “cutaway” button

The system consists of two interrelated processes: draining and supplying water. Let's take a closer look at the mechanism of operation.

Essential elements

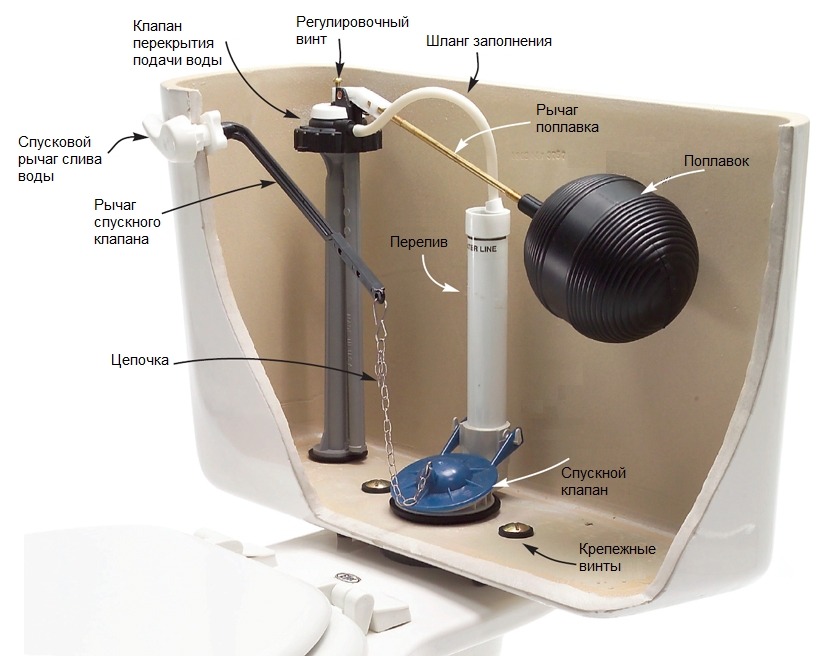

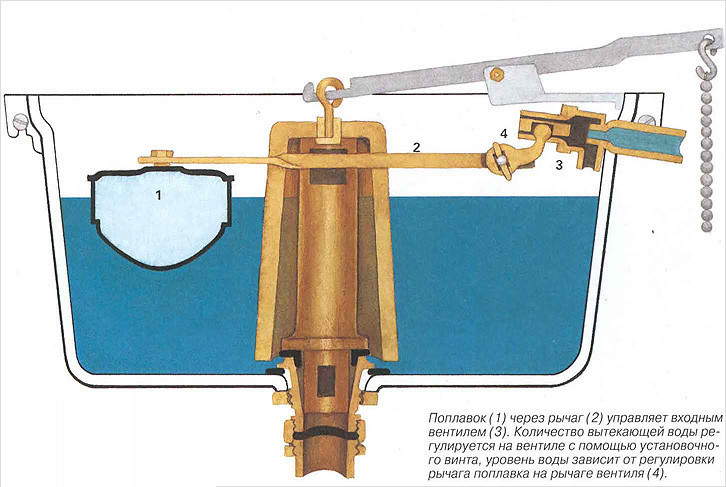

Technically, the tank is a reservoir with 2 (or 3) openings for supplying and draining liquid and contains three main mechanisms:

- inlet valve;

- a buoy on which the water level depends;

- lever system.

The liquid is supplied via a flexible water hose. The feed can pass through an opening located:

- on the side (left or right), the float is mounted on the edge of a horizontal rod connected to a ball valve;

- at the bottom, the float element is connected to a vertical lever built into the liner.

Scheme of work: as the water level in the storage tank drops, the float simultaneously drops (air holds it on the surface).In the lower position, it activates the water valve and rises higher until the tank is filled, then blocks further liquid flow.

The float component can be of two types:

- piston - equipped with a sealing gasket; when the tank is filled, it presses on the valve and shuts off the flow of water;

- membrane - this is a modern option, it is a silicone or latex membrane that operates almost silently and is reliable in operation.

Another important element is shut-off valves that regulate the flush into the toilet. We'll tell you more about its structure later.

Important! The pressure can be adjusted to reduce fluid consumption, but its minimum volume will not clean dirt well.

Sectional diagram:

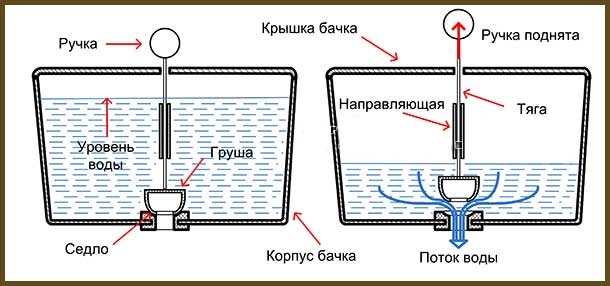

Operating principle of the drain system

This regulator performs two tasks:

- blocks accidental flushing into the toilet (blocks the opening until the button is activated);

- protects the tank from overfilling (via an overflow tube), interfaces with a lever and controls the liquid pressure when draining.

Technically, the circuit can be presented in the form of a lever, a pneumatic chamber or a rod (handle), their activation leads to the release of liquid.

Products are widespread and popular with one or two keys. Pressing the solid button releases the water completely, and the double button has both full and half volume modes. In some models, one button combines both modes (the depth of pressing determines the amount of fluid released). This allows you to save water resources if there is no need to completely empty the container.

Types of toilet cisterns

Products vary depending on the material:

- ceramics: characterized by reliability and affordable price;

- metal: it is characterized by durability, but has an unattractive appearance;

- plastic: stands out for its minimal weight and ease of installation.

By location and installation method:

- above the toilet: the components are connected by a drain pipe, a powerful pressure is created here (the greater the distance, the stronger it is), a chain is used for flushing;

- attached to the device (compact toilet): the most common option;

- built into the wall of the room (hidden installation): a release key is mounted outside the wall.

On a note! The shape and appearance of the products vary, but they are usually made with a volume of 4 or 6 liters, and the drain openings have standardized parameters.

Nuances of troubleshooting

If there is a malfunction with the supply or drainage of fluid, this indicates the need to repair the tank. Let's consider situations that may arise.

Liquid fills the container above or below the required level

We adjust the float so that the volume corresponds to the specified parameters. If the manipulation does not work, perhaps the problem lies in the levers; their failure will require replacement of the system.

On a note! It is recommended to replace a worn inlet valve with a new one; repairing it will not cost much effort.

Water is continuously collected and immediately flows into the toilet bowl

The problem is the buoy. Possible sources:

The filling valve is damaged. This is due to wear of the cuff in the piston displacer or membrane. These parts will require replacement.

The filling valve is damaged. This is due to wear of the cuff in the piston displacer or membrane. These parts will require replacement.- The lever is in the wrong position, bent - return it to a horizontal position, about 20 mm below the water supply opening.

- The float is not functioning.

Possible malfunctions of the buoy, their elimination:

- The part may become cracked over time, fill with liquid, and sink. The defect is corrected by installing a new element.

- The axis of the control lever has failed. Replace with a piece of thick wire (nail).

- The problem is the stop cap. A similar part can be made from a dense base.

Important! Do not rush to completely change the mechanism; carefully check the functionality of each element. In many cases, minor repairs will be sufficient.

The tank fills with a loud noise

Let's solve the problem by adjusting the size of the filling opening, or by installing a plastic (rubber) tube in the container so that water flows through it. We will need a pipe within 35 cm, one end of which is connected to the inlet. When the tank is empty, lower the second edge to the very bottom. Noise effects will be significantly reduced. However, this method only works in products with top eyeliner.

The tank is leaking

The obvious reason is screws are rusted or rotted, securing the container to the toilet shelf. We purchase new fasteners and dismantle the tank:

- use a valve to turn off the water;

- wait for the product to dry;

- remove the nut securing the inlet valve and disconnect it;

- unscrew the old fasteners connecting the tank to the shelf;

- separate the reservoir from the rubber cuff;

- we take out the bolts and replace both, regardless of their condition;

- we clean the contact surfaces between the container and the toilet;

- We perform the steps in reverse order: replace the cuff and place the product on top.

Important! We screw in the new screws carefully to avoid damage to the plumbing.

Upon completion of the work, we turn on the water, monitor its supply, and check for any leaks.Over the course of several days, it is necessary to check the reliability of the fastenings from time to time.

Reference! Bolts can be metal (such as brass) or plastic materials. The second option is preferable, because it does not corrode, and if tightly tightened, it will not damage the coating of the plumbing fixtures.

If old parts cannot be removed, you can use multi-purpose lubricant. In exceptional cases, use an angle grinder for dismantling.

Water constantly leaks into the toilet

It means wear of the drain valve membrane, located in its lower part and responsible for the strength of the connection. Replace the gasket:

empty the tank;

empty the tank;- disconnect the drainage device from the lever, unscrew the nut securing it;

- remove the worn tires and install a new part;

- reassemble in reverse order.

Important! A leak may appear if the overflow adjustment is incorrect. In its operating condition, there should be a distance of 2 cm between the liquid level and the cut of the drain tube. We eliminate the malfunction by re-setting the required filling limit.

No water supply

The problem can be caused by one of three reasons:

- Checking the supply hose. To do this, close the valve and unscrew the pipe from the tank. Place its free edge over a tank or other container and turn on the water. If moisture does not enter, the connector must be replaced.

- An option would be to clean the interface between the hose and the tank and the water pipe, using a screwdriver or other object. In some cases, these areas may become clogged with sand and other debris.

- The third source of trouble is a coarse filter that is covered with dirt. To check it, use duckbills to remove the element from the disconnected liner and clean it under a strong stream of water.Stubborn stains are softened with vinegar or citric acid (place in the solution for a couple of hours), then they need to be removed with a brush with stiff bristles.

How to replace the “insides” of the tank?

If a complete replacement of the “filling” is required, consider the dismantling procedure:

turn off the water;

turn off the water;- carefully unscrew the key;

- separate the lid;

- unscrew the supply hose;

- we disassemble the drain system from the top, which needs to be rotated 90º;

- unscrew the fasteners between the tank and the toilet;

- remove 2 nuts on the outer surface of the tank that secure the valve and drain, remove the equipment;

- We install a new structure and carry out the assembly in the reverse order.

The plumbing cistern performs functions that ensure the normal operation of the toilet. Knowing the device and the operating principle of its main parts, the owner will be able to independently carry out preventive maintenance and simple repairs of the product. Even if a complete replacement of the tank mechanisms is required, all this can be done on your own, without calling a technician.