How to change and install corrugation on a toilet

Time moves forward. More and more new technologies are appearing, old ones are being improved. The plumbing industry is also trying to keep up with the times. Many things become simpler, more convenient and of better quality. Even in such a familiar and ordinary thing as a toilet, today materials and devices are used that in many ways make our life more convenient and easier. Just recently, the thought of changing the toilet made many men's hair stand on end. After all, to do this it was necessary to turn half of the entire knot. But the corrugation appeared, and everything became easier.

The content of the article

What types of corrugations are there and why are they needed?

When choosing corrugation, you need to carefully evaluate its quality, and also pay attention to who and where it was produced. This is not idle curiosity; this approach will help you choose exactly the product that will serve for a long time and will not leak.

Reference. As a rule, domestically produced products are of worse quality than imported ones. Sometimes it happens that devices from Russian manufacturers simply do not fit tightly to the walls of the sewer pipe. This causes leaks. And during operation, they sag more often than imported ones. Sagging causes leakage.

The highest quality products are supplied to the domestic market by manufacturers from the Czech Republic, Italy and England. Study the packaging carefully, and if you have questions, do not hesitate to ask the sellers. The assortment is huge and choosing something worthy is not always an easy task.

Attention. Another parameter that you should pay close attention to when purchasing is the wall thickness. You need to choose corrugations that have dense walls - they will last much longer. In addition, you need to look at how the fastening is made. The sealing rubber should go from the end part to the herringbone. In this case, the product is more reliable and, accordingly, lasts longer. In addition to the pipe itself, do not forget to immediately buy silicone sealant.

Non-pressure corrugations made of plastic greatly simplify repair tasks in the toilet room. In Soviet times, the entire toilet system was connected to the sewer system using cast iron pipes. These were very heavy things and difficult to install.

Now everything is much simpler and easier. Cast iron has been replaced by plastic. Moreover, in our small apartments, where every centimeter is accounted for, a toilet corrugation seems to be the only way to solve the problem of updating the plumbing fixtures.

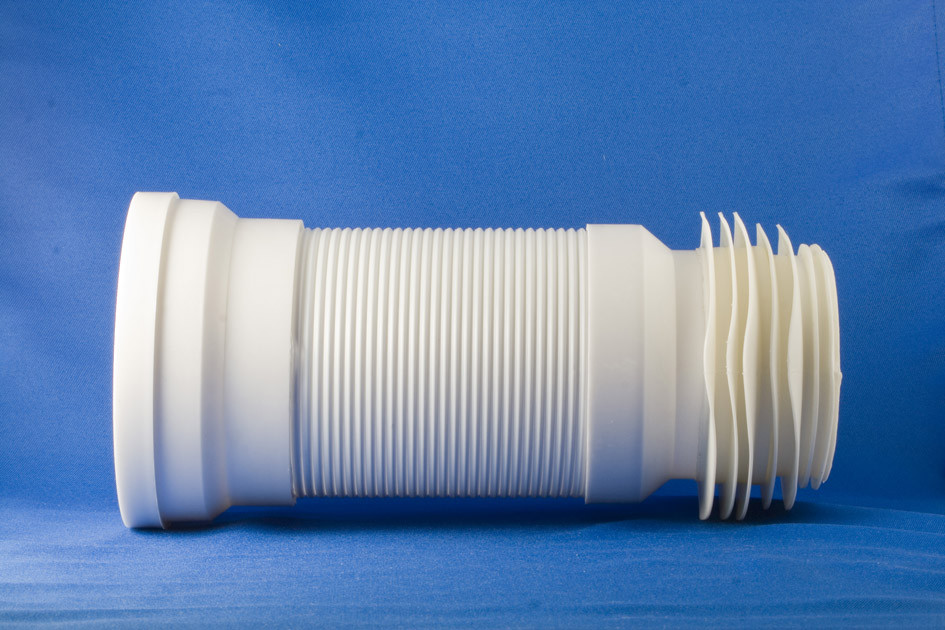

So what is corrugation? This is a kind of adapter whose task is to connect the toilet outlet to the sewage system. The pipe is quite wide and has a corrugated wall surface. The material for production is plastic.

The ends of the pipe are made in the form of a cuff. This is what makes it easy to connect the toilet and the sewer pipe. On average, the device reaches thirty centimeters in length, the diameter of the cuff along the outer edge is 13.4 centimeters, and along the inner edge - 7.5 centimeters.The diameter of the end of the pipe facing the sewer is 11 centimeters.

In installation, corrugated pipes are much more convenient and simple than cast iron pipes. This is due to the lightness of plastic, lower cost and long service life.

However, it is not necessary to use corrugation in all cases. Most often, a plastic pipe is used as connecting elements. This is due to its greater strength.

The use of corrugation is justified:

- In case of displacement of the toilet from the entrance of the sewer pipe. The most common reason for this is the laying of tiles. Or when moving it to another place. In such cases, an accurate connection is simply impossible and only the use of corrugation can help out. When installing a new toilet in another place, the length of the corrugation should be at least fifty centimeters.

- When the toilet outlet is non-standard. For example, when installing new plumbing equipment in a house with an old layout.

How to choose corrugation for a toilet

Depending on the technical characteristics and design features, corrugation is divided into:

- Hard and soft. Soft corrugations are made from thin plastic. This type is flexible and can be installed on any type of toilet, regardless of the outlet. It is easy to install, as it bends perfectly. The rigid type of corrugation is less elastic, since the thickness of the plastic is higher, but its wear is much lower.

- Without reinforcement and with reinforcement. Reinforcement gives the product more rigidity, strength, and makes it resistant to wear. Thanks to reinforcement, the service life is greatly increased. The corrugation is reinforced with thin wire, which is distributed in plastic along the walls. Typically, imported products are classified as reinforced.They cost a lot more, but in this case it’s not worth saving.

- Long and short. The length of the corrugation is selected depending on the distance between the toilet and the sewer drain. It does not need to be stretched much - this reduces the service life and deteriorates the appearance of the product. If the product is stretched, it will begin to leak faster.

Reference. For particularly unusual situations, you can find models whose angles are bent at forty-five, or even ninety degrees.

To accurately install plumbing in a small room, you can purchase a corrugated pipe with a special outlet into which the drain from the bathtub or sink is connected.

How to change an old corrugation to a new one with your own hands

The need to work with corrugation arises before us in two cases:

- new plumbing fixtures were purchased;

- An old pipe started leaking.

Installing a new corrugation or replacing it is somewhat different in its technology. After all, in order to install a new corrugation in place of the old one, you first need to get rid of the damaged one. Accordingly, some preliminary preparation is required:

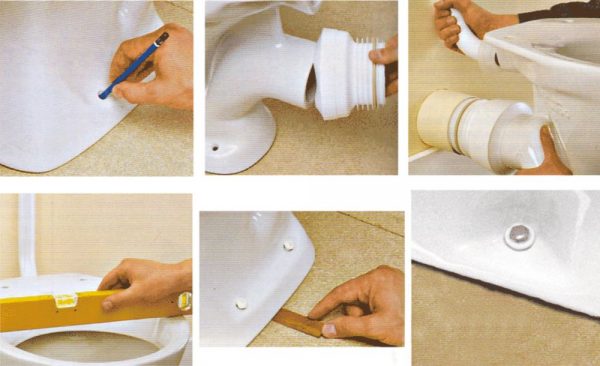

- Initially, you need to drain all the water from the toilet, turn off all structures and disconnect the pipes.

- Clean off all old cement.

- Remove any remaining sealant.

- Clean and rinse the sewer pipe.

All further actions are performed in a certain sequence:

- We treat the places where the pipe connects to the sewer and toilet with silicone sealant.

- We stretch the corrugation (make sure that this is done evenly along the entire length and without distortions).

- We insert one end of the corrugation into the hole in the sewer pipe, and install the other end into the toilet outlet.

- Fill the toilet with water.

- We look at the joints to see if there are any traces of water leaks.

- We remove the corrugation and mark the places where the toilet will be fixed.

- We place our entire structure on the floor, fix it with bolts (the toilet should not wobble, we check its correct installation with a level).

- We install the adapter and reconnect the corrugation.

- To prevent leaks, we treat all joints with sealant.

- We fill the screed and finish the floor.

We hope that our recommendations will help you install the corrugation on the toilet yourself.