Replacing the antenna socket on a TV

Before repairing or replacing the antenna socket, you need to carefully study the causes of the breakdown and also become familiar with the replacement procedure.

Before repairing or replacing the antenna socket, you need to carefully study the causes of the breakdown and also become familiar with the replacement procedure.

The content of the article

When do you need to replace the antenna socket?

It happens that the antenna socket of the TV fails; there may be several reasons why the malfunction occurs.

- It often happens that when moving equipment, they forget to remove the antenna plug from the connector on the TV.

- Sometimes pets play with the cable and loosen the connector, thereby rendering it unusable.

- This part breaks due to switching several cables from different signal sources.

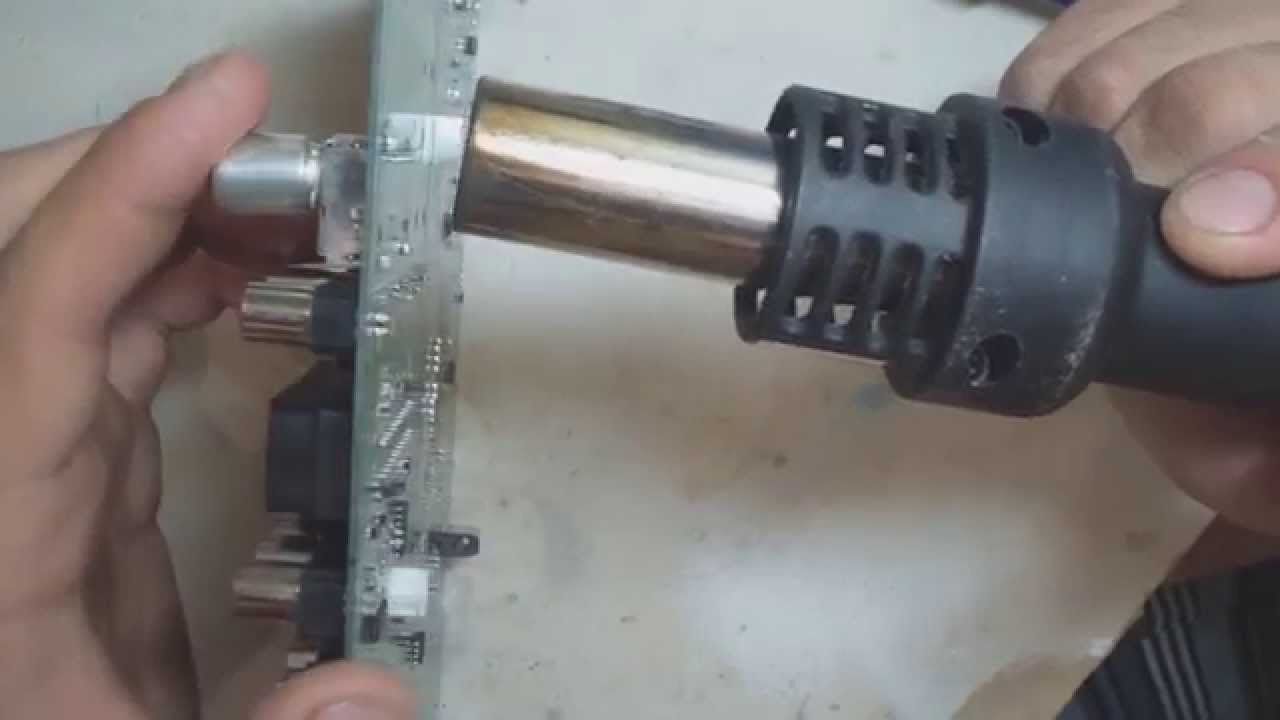

TV antenna socket repair process

If the socket comes off and the conductor, which is located in the center, is broken, but part of its element is located in the tuner board. You must carefully perform the following steps:

- The cover of the device is removed.

- Rotate the board in such a way that the soldering process is convenient.

- The capacitors located nearby that prevent the lid from opening must be bent, the same can be done with the side strips located next to the lid, thus pulling it back and removing it.

- It is necessary to indicate with marks how the covers were positioned; it is important not to confuse them, since they are equipped with contact lamellas.

- After removing the closing elements, they begin to repair the old connector.

- A wire is soldered to the central contact core.

- Before soldering, the wire is bent to the protruding connection to pass into the existing hole located on the device board.

- The remaining central contact is carefully soldered with a cleaned soldering iron. Everything must be done carefully to avoid tin flooding of nearby parts, and make sure that they do not shift.

- Before the soldering process, the place where the conductor is installed is inspected very carefully; as a rule, planar elements are soldered there.

- It is important to choose the right angle when heating the conductor so as not to touch the printing pad.

- Next, the conductor element is carefully removed, this is done using tweezers.

- Then the updated connector is inserted, and the wire is inserted into a special opening on the device board.

- Next, the tuner is soldered to the body of the socket, then the main conductor.

If you don’t want to repair used connectors, you can replace it with a new product (with a whole central conductor). Sometimes there is a protrusion on the flange, at the point where the base of the socket is soldered, in some cases it needs to be cut off.