How to sew with a double needle on a sewing machine

Every year more and more special accessories appear on sale, allowing you to significantly expand the capabilities of household sewing equipment. Among the abundance of presser feet, rulers and other devices, the double needle deserves close attention, because with its help you can easily and quickly perform a lot of decorative seams and operations.

Every year more and more special accessories appear on sale, allowing you to significantly expand the capabilities of household sewing equipment. Among the abundance of presser feet, rulers and other devices, the double needle deserves close attention, because with its help you can easily and quickly perform a lot of decorative seams and operations.

The content of the article

Device and types of double needle

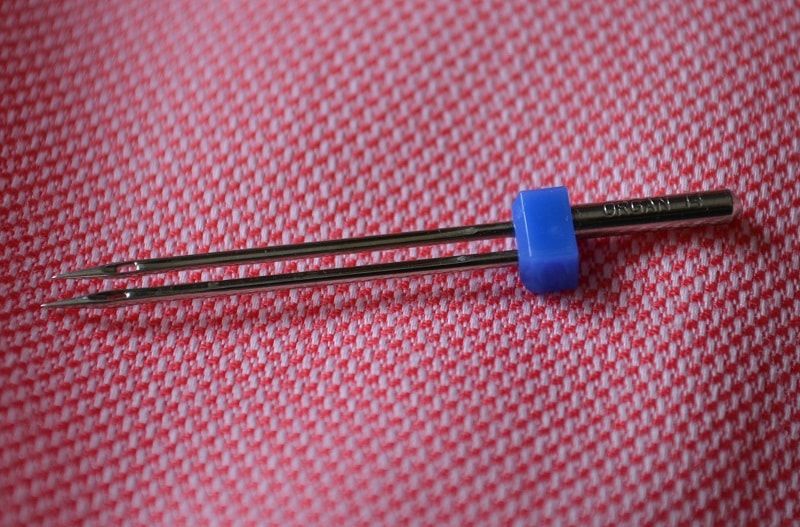

The main distinguishing feature of a double needle is the presence of two blades at once, attached to the flask using a jumper. Thanks to this design, it is possible to lay 2 lines at the same time. This structure makes it possible, without much effort, to form 2 absolutely identical lines with the same distance between them along the entire length.

ATTENTION! Double needles intended for old-style machines and new household machines have slight differences in structure. Not every craftswoman is able to notice that the grooves - the indentations located on the blades of the needles - are several millimeters longer or shorter than usual (especially if she does not know about their presence), but the capricious technique immediately identifies this feature and refuses to sew. Therefore, when purchasing, be sure to focus on this nuance.

There are twin needles:

- for decorative stitching, low-stretch fabrics;

- for hemming knitted fabrics (twin stretch).

They differ from each other:

- blade diameter;

- space between the points.

They are usually marked with two numbers separated by a fractional line. Where the larger value corresponds to the needle number, and the smaller value corresponds to the distance between the points.

Needles with a distance of 4 to 6 are used:

- for hemming lower cuts;

- for sewing pockets and flaps;

- for seaming connecting seams to improve the aesthetic appearance.

Samples with a distance between blades of 1.6, 2.0, 2.5 are more often used to form decorative finishing stitches. Using threads of different colors or shades allows you to achieve a highly artistic effect with a minimum of effort.

Of particular interest to many seamstresses is the combined double needle, one blade of which is regular and the other is winged. This design is indispensable when hemming tablecloths, napkins or finishing light clothing.

Features of working on a sewing machine with a double needle

You should immediately note that the seams made with such a needle have a decorative purpose rather than a functional one. This is why they are used:

- in finishing works;

- when hemming the bottom of the product and sleeves;

- when sewing pockets.

They are never used for those nodes where significant load is expected.

Despite the fact that you can sew with a double needle on any household machine that has a zigzag function, not all manufacturers equip the equipment with an additional spool pin and paired thread removers and thread guides.Of course, enterprising seamstresses can easily get out of this situation by using a bobbin winder as a second rod, or simply installing 2 spools on one rod (sometimes you have to use a bobbin with wound thread instead of a spool).

The innovative method has a right to life, but it is not applicable to all household machines. Some capricious models tolerate such experiments very “painfully”. For their operation, it is very important that the threads unwind at the same speed and enter the needle with identical tension, because even a slight imbalance leads to stitch defects.

In such cases, long hours of setting up the machine and kilometers of sewn samples will not lead to the desired result - the stitches will turn out to be of poor quality. To solve this problem, it is best to purchase a creel. It doesn’t matter whether it’s a sewing accessory purchased in a special store, or a homemade holder for 2 spools.

Increasing the length of the thread from the spool to the thread tensioner, together with the same speed of unwinding the bobbins, will do the trick - the quality of the seams will increase several times without any additional manipulations with the equipment.

Installation Rules

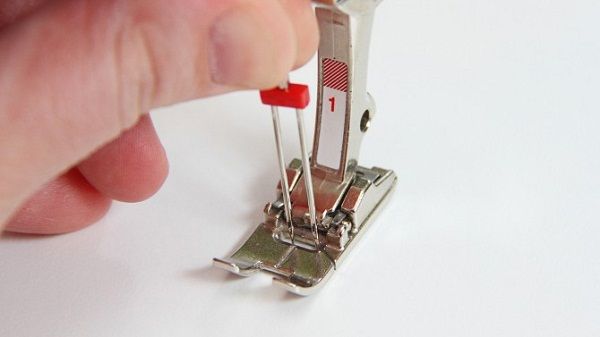

In order to install a double needle in a sewing machine, you should follow the same rules as in the case of a regular one:

- Take a close look at the needle flask; one side of it always has a slight truncation, the so-called flat. This design feature allows you to accurately place the needle in the machine. The flat side should always be facing away from the seamstress.

- Make sure that the distance between the blades does not exceed the size of the slot in the work plate.

- Insert the flask into the hole until it stops and tighten the fixing screw tightly.

- Insert the bobbin with the thread wound into the hook.

- Place 2 spools on the rods and thread according to the instructions for the machine. In models that are not designed with paired thread tensioners and thread guides, the threads of both spools are threaded together and only near the needle - the first of them goes into the thread guide, and then is threaded into the hole, the second is immediately threaded into the hole, bypassing the thread guide.

ATTENTION! When threading a sewing machine with a double needle installed, the thread from the left spool should go into the left blade, and the thread from the right spool, respectively, into the right blade.

How to sew with a twin needle

Unfortunately, there is no single algorithm by adhering to which it would be possible to force sewing equipment to perform perfect stitches the first time. Few craftswomen manage to immediately set up the machine in the right way when sewing; very often it:

- skips stitches;

- breaks the thread;

- tightens the fabric;

- does not form stitches;

- forms an unaesthetic bottom seam.

However, with due diligence and methodical experimentation, you can achieve an ideal result on any sewing machine that has a zigzag option.

ATTENTION! When sewing stitches with a double needle, the thread tension should be minimal. If, when stitching parts with a regular needle, the thread tensioner toggle switch is set to 5–6, then when stitching with a double needle, it should be moved to position 1–2.

When working, it is very important not to violate the correspondence between:

- fabric thickness;

- needle number;

- thread number.

Even if, when sewing with a single needle, failure to comply with these conditions does not lead to noticeable flaws, then it is worth installing a double needle on the machine, and all possible seam defects will appear fully.

Therefore, before starting work you should:

- make sure that the thread and needle are in numerical correspondence;

- make sure that the selected type of needle is suitable for sewing this type of fabric;

- check that the machine is refueled correctly;

- reduce thread tension;

- make a sample.

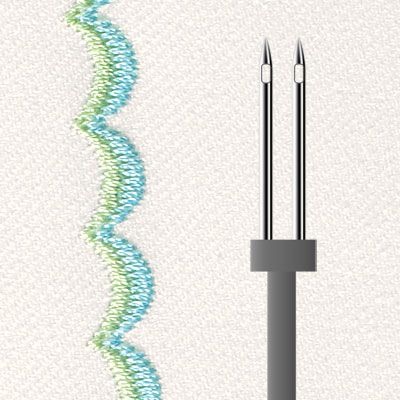

A high-quality seam made with a double needle consists of 2 parallel lines on the front side and a zigzag stitch on the back side. In this case, the fabric between the rows of stitches should not be pulled together, and the lower thread should protrude outward.

How to make decorative designs and finishing

To perform decorative stitches, remember that the selected pattern cannot be too wide. The blade moving from side to side should not extend beyond the hole in the plate. Otherwise it will come into contact with the metal and break. To minimize the risk, it is best to choose needles with a small point spacing of 1.6 mm to 2.5 mm. Before starting work, check the patency of the needles at idle speed without threads, slowly rotating the flywheel by hand.

Sometimes clothing design involves ruffles. You can make them using the same double needle. You will need for this operation:

- a needle with a large distance between the points (5.0–6.0 mm);

- a thin elastic band that should be wound onto a bobbin instead of thread.

Then all that remains is to sew a stitch; the inserted elastic band will itself create even, neat gathers.

The presence of a special foot and a double needle in tandem allows you to perform a lot of additional operations:

- sew on cord or thin beads;

- form tucks.

Rules for safe operation

The impact of the tip on a steel plate, at best, simply leads to bending of the part, and at worst, to a violation of integrity. At high speed, a fragment of the rod may well bounce off and cause serious injury. Therefore, before you start sewing:

- check the alignment of the needle and the slot in the plate;

- Be careful to ensure that the machine is set to straight stitch only and does not accidentally switch to zigzag, decorative stitching or embroidery.

Always remove pins and bobby pins before using the machine. Even if they do not come into contact with the rod and do not violate its integrity, they will loosen the rack.

Do not use blunt, much less bent, needles. The presence of such defects will inevitably lead to failure.