Do-it-yourself electric garden branch chopper

The process of pruning trees is usually accompanied by a large amount of debris, which ultimately remains on the site. Disposal of such waste often becomes too labor-intensive. If large branches can be used for heating a house, then small brushwood simply accumulates in mountains on the territory, and subsequently it has to be burned at the stake.

However, there are more profitable and practical options for using such waste. For example, as an organic fertilizer. But for this it is necessary to first chop branches. In addition, wood shavings have the ability to retain moisture, thanks to which they can nourish the soil well, increasing productivity and reducing the number of weeds in the summer and protecting tree roots from severe freezing in the winter.

Another good use for shredded wood is wood chips for lighting and cooking smoked food.

To process trimming waste into shavings useful for the household, a chopper (shredder) is used. The cost of factory copies is high, so it is better to make such a unit yourself.

The content of the article

Basic elements of a garden shredder

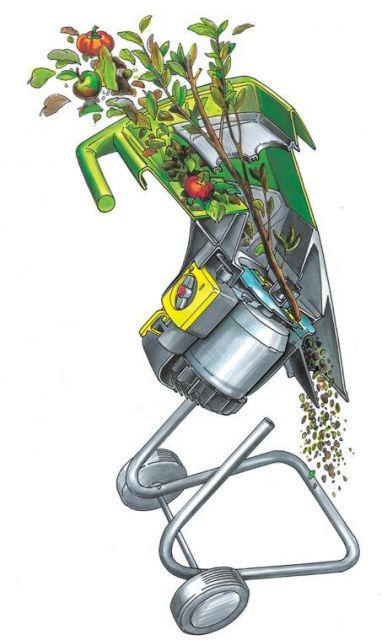

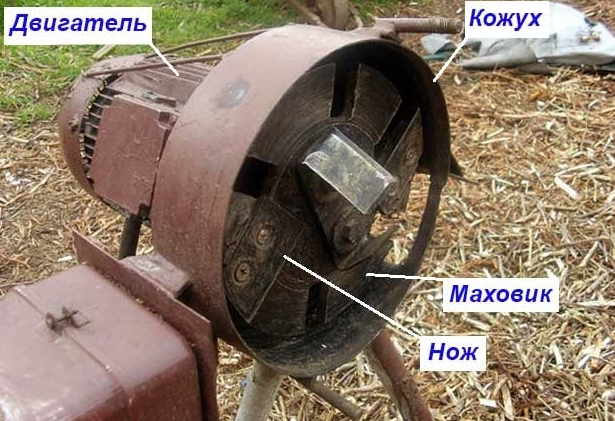

In order to assemble a shredder yourself, you first need to study what the mechanism consists of and the principle by which it works. Knowing all the nuances, it will be possible to make changes to its design in the future. Elements common to all shredder models:

- Power unit.

- Cutting element.

- Starting system.

- Frame.

- Protection casing.

- Box for receiving branches.

The frame is assembled from scrap materials, often using ready-made frames from various products or angular-section metal. The casing is made of durable material, since this structural element is constantly exposed to chopped parts of vegetation. Old buckets or small barrels are often used as boxes.

Depending on the type of design, the device can be stationary or mobile. In the case of the latter, in addition to all of the above, you will also need wheels and a handle to move the shredder.

The principle of operation of the device is as follows: through the shaft, rotation is transmitted directly from the motor to the knives. Arrangements are also possible where the role of the shaft is played by a chain or belt drive. The vegetation is fed directly to the knives, and after the cutting process it ends up in a box. In different versions, the operating principle may be similar to either a meat grinder or a coffee grinder.

Making a homemade garden shredder: where to start

When starting to develop such a tool, you need to clearly understand that it is unlikely that you will be able to construct something that works without having metalworking skills and the ability to carry out such work. The production of parts such as shafts or bearing housings is impossible without special machines, so you need to either order work on their production separately, or look for ready-made units from old equipment.

Manufacturing is divided into the following stages:

- Choice of design.

- Search for power unit.

- Calculation of the main gear.

- Calculation of parameters and production of spare parts that require a lathe.

- Frame design.

- Installing the power unit on it.

- Fixing the protective casing and box.

Design selection

During the preparation process, you need to decide on the operating principle of the future tool. The design, which is chosen based on the needs, will depend on this:

- if small chips are required, it would be best to make a shredder from circular saws;

Small shavings are used to prepare compost, mulch or briquettes for subsequent heating of the house.

- if you need a large fraction, then the option where a circular saw is taken as the base will be the best;

- If you need to process small branches in large quantities, a disc crusher is suitable.

Engine selection and belt drive calculation

The power of the selected engine determines how thick branches the shredder can process. Based on this, there are several recommendations for choosing a drive:

- The power unit power for the crusher should be in the range from 2.5 to 3.5 kW. A shredder with a 1.5 kW motor will only be able to crush grass and small branches; more than 4 kW will run idle and waste too much electricity.

- Power is about 5–6 liters. With. for a gasoline or diesel engine - a guideline for normal operation. This kind of power units can often be seen on walk-behind tractors. The number of drive revolutions does not matter, since the rotation speed will be regulated using a V-belt drive.

- The blades must have a rotation speed of about 1500 rpm in order for the shredder to work reliably with branches of medium thickness.To do this, you need to correctly select the diameters of the pulleys that will regulate the transmission of torque. It is this parameter that will be decisive. For an example of calculation, you can take an engine at 3000 rpm. Reducing the speed to 1500, we get a twofold difference in the diameters of the pulleys. If the size of the driving pulley is 120 mm, then the driven pulley, being on the working shaft, should have a diameter of 200 mm.

- When making pulleys, you can make them with 3 or 4 grooves. In this case, when rearranging the belt, the revolutions of the working shaft change. This will allow the tool to work in different conditions - both with large branches and with something smaller.

Do-it-yourself electric garden shredder: options and manufacturing stages

The task of designing and assembling a homemade shredder may seem difficult only at first glance. In fact, a person who knows how to work with a tool will cope with this task without any problems.

Initially, you need to draw a detailed sketch of the future instrument. All dimensions should be very accurately indicated on the diagram, especially those nodes that are considered key. This procedure will greatly simplify the task of making a chopper.

As a rule, the basis for a shredder is some old unnecessary tool that is no longer useful. The most common conversion schemes are the following.

From the Bulgarian

This tool is available in almost every household. It is used everywhere, including as a donor for the chopper. The advantage of this scheme is a powerful power unit.

From the washing machine

When throwing away an old washing machine, you can keep at least the engine from it, since it is perfect as a basis for a shredder. With this tool you can easily cut small branches and grass.

From a circular saw

There is no better base option for a chipper than a circular saw. A tool made from it will perfectly turn branches into large chips and shavings, for which there is always a use on the farm.

To simplify the task, you can install the mechanism directly on the working saw drive, using its base instead of the frame. This will significantly reduce the number of steps required to manufacture a shredder.

From a drill

The main thing you need to understand is that the drill drive is much weaker than all the others listed above. Because of this, it can be used for chopping grass, leaves, and various vegetables for feeding animals.