Why the garden sprayer does not pump up pressure

Largely garden sprayers supplied with a pump. The latter is designed to create internal pressure. If, when using the device, instead of spraying, it simply produces a stream of liquid or the pressure leaves much to be desired, the problem should be corrected. Opening the tank, removing and inspecting the pump unit will help determine the cause of the malfunction.

The content of the article

Reasons why the sprayer does not pump up pressure well

If the pressure is low, then the required fluid flow will not occur. The reasons for such a failure in the normal operation of the device may be:

- Filter clogged. This part is a long stick that is located in the handle of the device. You can clean it yourself. To do this, unscrew the hose from the handle, pull out the filter using tweezers and rinse it.

- Lack of power. The reason is the low battery charge. Fixing the problem is as easy as shelling pears: you just need to turn it on for charging.

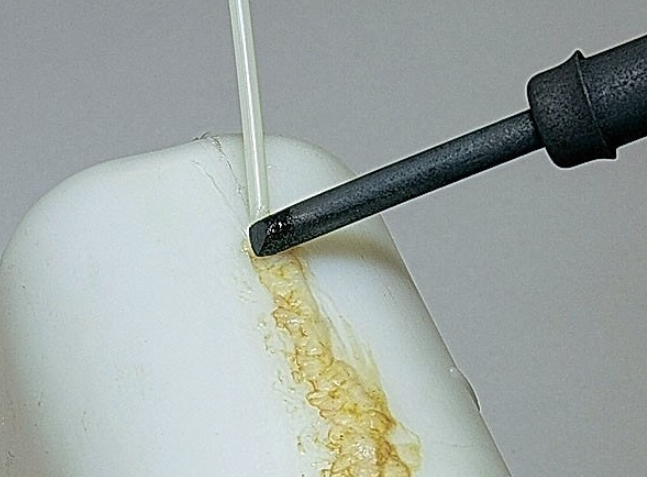

- Wear of pump parts. To check this, you need to open its block. When the adjusting shims, which are located on the opposite side of the drive shaft, wear out, the distance between the ends and the adjacent plates can be increased.

- Damage to parts. If one of them is cracked or worn, it needs to be replaced.

It is quite possible to fix the above problems yourself: this does not require any special skills. But if you lack confidence in your abilities, it is better to give the equipment to a specialist. This will guarantee that the situation will definitely not worsen, i.e., complete breakdown.

How to Prevent Pressure Problems with Your Garden Sprayer

Many of these problems can be avoided if you follow simple recommendations for caring for your equipment. These include:

- Cleaning injectors after use.

- Thorough washing and drying at the end of the summer season.

- Lubricating all rubbing areas. For gaskets, it is always a good idea to treat them with special machine oil, but regular Vaseline will also work. Lubrication prevents them from cracking and leaking.

- Proper storage of equipment. It should be placed in a dry room to avoid corrosion.

Regardless of the type of sprayer, it does not require any complex maintenance steps. Proper handling and timely preventive measures prolong the life of equipment.