Do-it-yourself trailer brakes for a walk-behind tractor

Without brakes installed on walk-behind trailer, the device is likely to get into an unpleasant situation when descending from a hill. Homemade brakes are removed from a car or motorcycle and converted to work on a tow hitch.

The content of the article

What brakes are needed for a walk-behind tractor trailer, what else is needed?

There are different types of brake mechanisms. For example, hydraulic, locomotive and so on. When choosing brakes for your unit, you need to pay attention to their features.

Most often, parking ones are installed on the trailer to the walk-behind tractor. However, they don't fit him too well. This variety is not suitable for heavy loads: it is difficult to stop a full trailer. In situations where the device is going downhill, they become even more useless.

Another type is band brakes. When installed on a trailer to a walk-behind tractor, they also do not perform their main functions, so installing them is mostly useless.

Brake design drawing, principle of operation

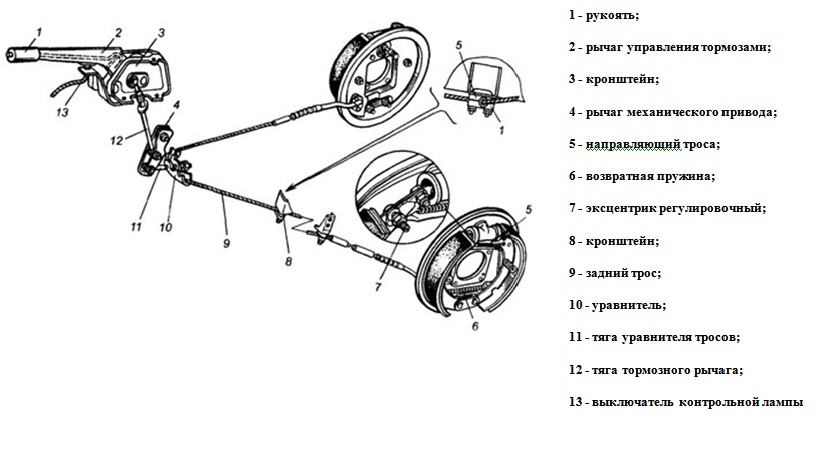

The mechanism includes three cables, two of which are connected to the wheels, and the remaining one to the lever. To apply the brakes, you must operate the lever.It is connected to the mechanism by a front cable, which starts the brake drive, which transfers the work to the mechanism. The front cable, activated by a lever, pulls the other two.

The adjusting nut can change the length of the drive. This device is useful if the brakes have been removed from a vehicle that is not suitable for its dimensions. To remove them from the hitch, you need to move the lever back. This is done using a return spring located on the main cable, the brakes themselves, or the brake cable equalizer.

Procedure for installing brakes yourself

Many walk-behind tractor owners planning to make homemade trailer brakes decide to remove them from their old motorcycle. You will need to take brake pads and a metal drum from it. We take a motorcycle wheel and get rid of the rim and spokes, leaving only the disc. We remove the rod and cable from the latter, and then sharpen it.

We put the drum on the wheel hub and wrap the free space with wire. We place the machined disk on the axle, cover it with a bushing and weld a piece of pipe to it. To control, we place a lever and attach a cable to it.

Brakes from VAZ

We insert the front axles together with the hubs removed from the old VAZ car into the axial part of the towing mechanism. We connect these parts to the rear brake drums. It is recommended to take used brakes from a VAZ 2101-07, since they have the largest diameter, which facilitates the operation of the mechanism. We take brake pads from the same brand of car so that the parts fit together. Using rods and levers, we install the blocks on the trailer.

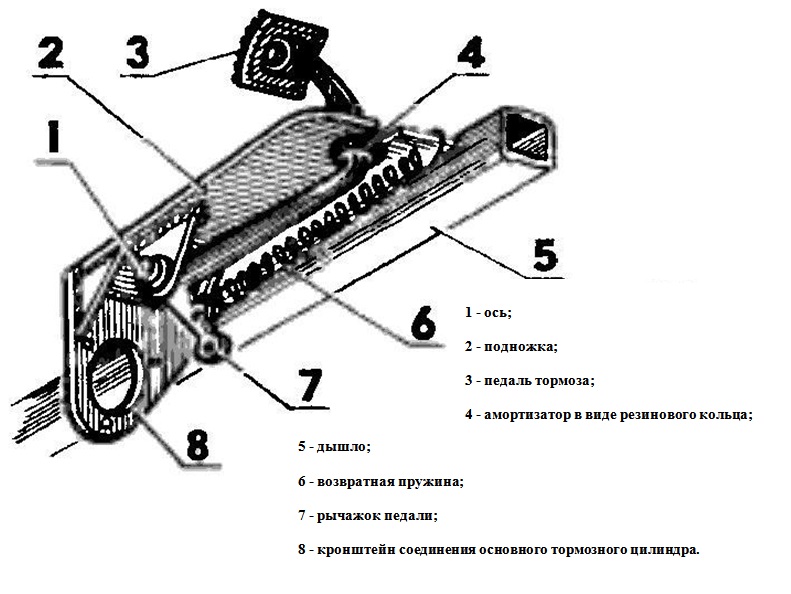

We insert the brake pads into the drums, press them with a transverse rod and weld them to each other.Next, we attach the main link to the brake pedal located on the trailer drawbar.

On the upper and lower sides of the transverse rod we attach guides by welding along which the rod will move during braking. Due to this, the brake pads will remain in working condition and will not move after the drums.

Homemade brakes, similar to those described above, can be made from any hubs equipped with brake drums. These could be spare parts from Moskvich, Volga or Zhiguli.

DIY brake installation option in the video.