Do-it-yourself walk-behind tractor trailer

The walk-behind tractor is used for land work in agriculture. Farmers love it for its versatility and the ability to save money on technical devices. Additional units are connected to the unit for different types of work. For example, you can turn it into a mini-truck by making a trailer with your own hands.

This auxiliary device is purchased in stores specializing in gardening equipment. You can also buy additional trailers for it there. The product will cost a considerable amount, and a hand-assembled unit costs three times less.

The content of the article

Design features of a trailer for a walk-behind tractor

The towing mechanism consists of a body, frame, hitch and wheels. There are three main types of such devices. They differ in their maximum transportable weight:

- Carts with one axle have the simplest and cheapest design. They are capable of transporting loads up to 70 kg.

- Carts carrying between 110 and 120 kg are considered the most versatile and inexpensive option.

- Structures with a load capacity of more than 120 kg. The frame and cladding are made of expensive material.

The trailer's folding mechanism is needed for loading and unloading operations. This is one of the additional elements that improve the design and facilitate the operation process.To provide stability, regardless of the walk-behind tractor, stops should be used.

The simplest frame creates a load on the axle, hubs, and wheels of the cart. A more complex design affects the towbar carrier.

What is needed to make a homemade trailer for a walk-behind tractor

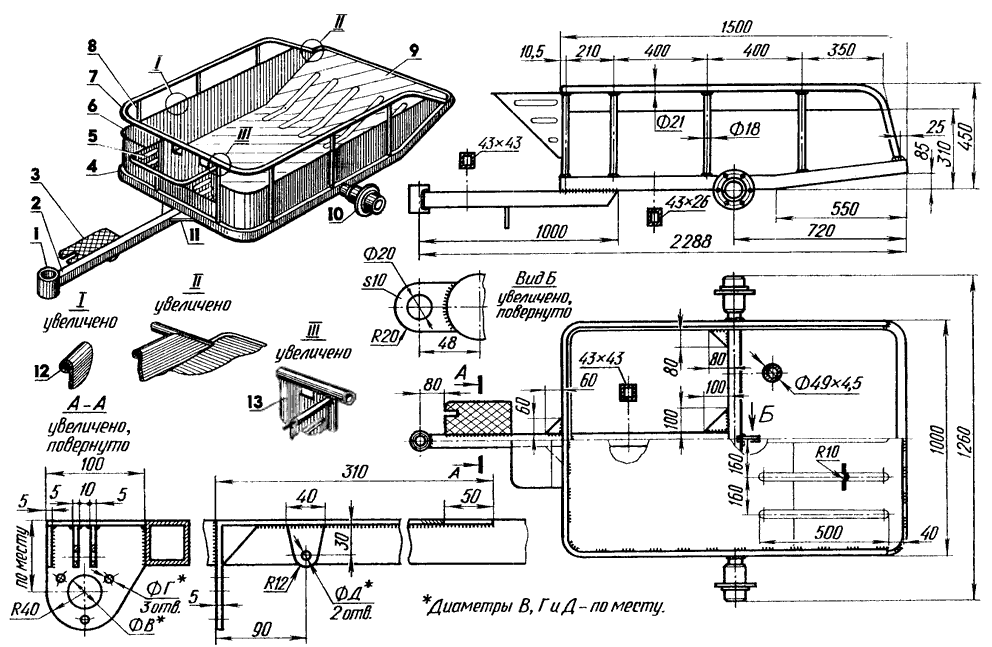

Cart for walk-behind tractor It has a complex structure, so it is manufactured in several stages. Before you start working on a homemade unit, you need to properly prepare. First of all, you will need a clearly drawn up schematic drawing of the future mechanism.

Next you need to collect a set of materials. A homemade trailing mechanism consists of the following elements:

- iron pipes - 60*30 mm and 25*25 mm;

- wheels and springs - 2 pcs.;

- duralumin plates - 2 mm;

- steel plates - 0.8 mm;

- set of bolts and nuts;

- channel No. 5.

For assembly you will need the following tools:

- Bulgarian;

- welding machine;

- jigsaw;

- screwdriver

It is worth setting up a special place for working on a walk-behind trailer. This must be taken care of so that nothing interferes with the creation of the mechanism. It should be organized in such a way that all the necessary tools are at hand at any time of work.

How to make a trailer for a walk-behind tractor with your own hands

We cut out metal parts from prepared sheets. The dimensions of each structural element must correspond to the diagram.

Creating a Frame

First, we will make a frame for a walk-behind trailer. The metal part must be reliable and durable. These qualities will allow it to withstand heavy loads without deformation. The frame is made of metal profiles. The more elements the frame lattice has, the more load-bearing the trailer will be.The profiles are connected by welding. Particular attention should be paid to the corners of the structure.

Let's create a standard version with a rectangular cross-section and a connecting angle of 25*25 mm. Two 60*30 mm steel pipes are suitable as the left and right side members. To create the front and rear crossbars, we will take smaller profiles. To form the lattice, the structure is combined using five transverse pipes.

Body manufacturing

We create the basis for the body. We attach perpendicular profiles 25*25 mm to the metal mesh. We connect them with longitudinal metal tubes. Then we weld four vertical posts to the corner parts of the structure. We attach the strapping to the tops of the posts.

If you want to install a wooden body, you should choose boards 20 mm thick. At the corners of the structure we fix reinforcing metal linings. We place 3 support frames on the cart frame and use them to secure the body part. We take beams measuring 50*50 mm. Bolts are used as fastening elements.

If you plan to install folding sides, then the sides and rear sides of the frame must be made in a separate order. We take narrow tubes and combine them into rectangular structures.

Subsequent stages of work

The chassis consists of a long pipe and two axle shafts welded together. Channels are installed at the edges and in the center of the pipe to secure it to the frame. We weld the latter to the trailer beam. We make a drawbar from two 60*30 pipes. We connect the front parts of the pipes and fasten them to the base. We fix the rear parts to the side members. Leave an overlap of 20 cm.

Wheels with hubs from a motorized stroller, garden cart or Zhiguli are suitable for the towing mechanism.The only requirement for the wheels is that they must be the right size for the towed structure. We make the wheel axle from a durable steel rod. Its length must match the dimensions of the body.

We attach the longitudinal shaft and side members to the axle by welding, using metal corners for fastening. We strengthen the structure with scarves. We put the bracket support on the side members.

We make a pallet from a metal sheet 2 mm wide. First, it is lightly processed with a welding tool, then a seam is made around the entire perimeter. To create the cladding of the frame you will need metal, boards and corrugated sheets. The bottom lining is made of duralumin, the sides are made of metal sheets. We fasten the casing with bolts.

To attach the trailer to the walk-behind tractor, we use a console. It must be compatible with the hitch. The upper part of the console is an axis with a swivel unit, equipped with two bearings and anthers.

With certain skills, you can make a trailer for a walk-behind tractor with your own hands in 2–3 days. A homemade product will last for several years without needing repair. To give it a factory look, additional parts are attached to it: brake lights, side lights.