Do-it-yourself rake for walk-behind tractor

Rake for walk-behind tractor help to rake, turn and double windrows of mowed grass. This is a convenient and effective device that facilitates the work of farmers during haymaking. If you put in the effort, you can create a good homemade rake with characteristics that are not inferior to factory models. To do this you will need a set of materials and welding skills.

The content of the article

What is needed to make a rake for a walk-behind tractor

To make a useful mechanical tool with your own hands, you will need to assemble a set of materials. The rake for the walk-behind tractor is made from the following raw materials:

- disk from a grain seeder;

- steel strip 170 cm long, 4 cm wide, 1.5 cm thick (wheels);

- 2 metal plates 9 cm long, 3 cm wide, 2 mm thick (frame fastenings);

- retaining ring;

- 2 squares 25*25 mm (stands for support);

- metal pipe with a cross section of 14 mm (axis);

- thick-walled pipe with a cross-section of 30 mm and a length of 140 cm (drawbar);

- metal wire with a diameter of 6–8 mm (working parts);

- set of springs

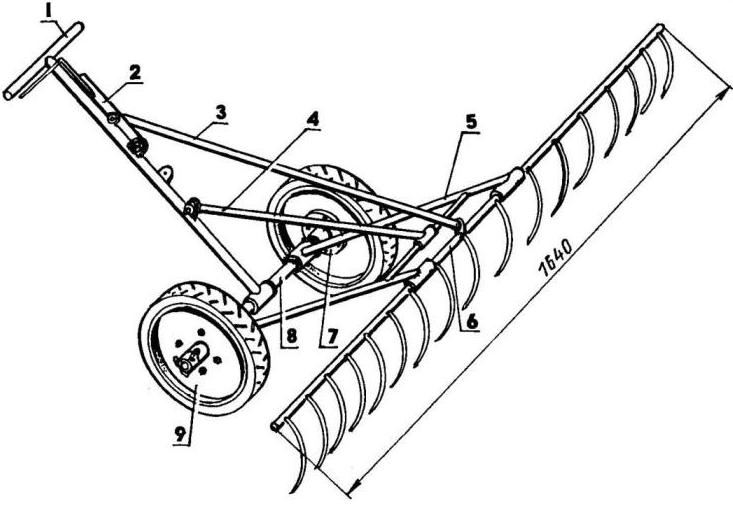

To design the device correctly, it is necessary to prepare a drawing of the rake. On it you can see the main structural components of the unit. The device consists of a drawbar (1), a lever (2), a rod (3), a strut (4), a stand (5), a hub (7), an axle (8), wheels (9), and the rake itself (6).

Do-it-yourself rake on a walk-behind tractor: manufacturing process

First we make the wheels. We take the disk removed from the grain seeder, remove the bearing from it and insert a metal rod inside. We wrap a metal strip around the disk and weld it to its end side using corners.

Let's make the basis of the future device. We thread the axle pipe into the wheels of the device, leaving 2–3 cm on the outside. We attach a locking ring from the inside, and drill a locking hole from the outside. At a distance of 10–12 cm from each wheel, we attach two steel strips on which the frame will be installed. In the central part of the axle we drill a hole for installing the drawbar.

Let's construct a working mechanism. We attach oblique supports to the wheel axle. They should be located parallel to each other. We grind the protruding parts with a grinder.

We attach a pipe with thickened walls to them - this is the drawbar of the structure. If you take a pipe that is not thick enough, it may not withstand the load created by the rake. We attach a loop to the end of the drawbar, forming a joint with the walk-behind tractor. We place locking rings on both sides of the pipe so that the rake acquires a stable position. We install a lever on them that will allow the teeth to be raised and lowered.

We make teeth for the working part of the rake. For this we use wire 6 mm thick. Give them a C-shape. We fix them by drilling or welding.

Installing additional elements - the seat on the drawbar and the spring on the lever. Lubricate moving parts with grease to reduce friction. If the teeth are too long to work with, shorten them.

We create reinforcement for the rake to avoid its breakdown in the future. To do this, take a metal plate 15*15 cm and strengthen the weak nodes with it.First of all, it is necessary to fasten the racks by welding a support to the middle. You should also strengthen your traction. Otherwise, a high fracture load will occur. After completing the manufacturing process, you need to check how the working part rises and falls and what force it creates.

Mechanical hay rakes allow you to cope with a significant amount of spring work. The made model is universal. It will fit any brand of walk-behind tractor. Horse rakes, which have been used by people in Russian villages since ancient times, were taken as a sample.