DIY bicycle cultivator

The summer resident’s spring efforts in cultivating the soil before sowing will be less burdensome if he acquires small-scale mechanization equipment, which includes cultivator. The price of a store-bought device seems prohibitive for many, so folk craftsmen (honor and praise be to them) offer ways to create such equipment from scrap materials. One option is to use some parts of an old bicycle for a homemade cultivator.

The content of the article

What is needed to make a cultivator with your own hands?

In addition to the base, from which you will need a wheel with a fork and a steering wheel, you need to prepare:

- circular saw blade;

- profile pipe 20*20 mm;

- reinforcement 8 mm;

- sheet steel;

- a 30 mm metal strip and a half-inch tube.

The tools you will need are a welding machine, an angle grinder, bolts, and a wrench.

How to make a cultivator based on a bicycle: steps

You will need a wheel with a radius of approximately 21 cm. First of all, the rod of the fork going to it is cut off. Then a steel plate is welded onto it.

Further:

- two profile pipes are fixed to the resulting peculiar steel platform using a welding machine (their length is selected depending on how tall the user of the homemade device will be) - they will serve as the basis for securing the steering wheel;

- to securely fix the pipes under them, it is necessary to make spacers - for the construction of the latter, fittings are used;

- in the upper part of the pipes are brought together, then the steering wheel is fixed (welded) to them;

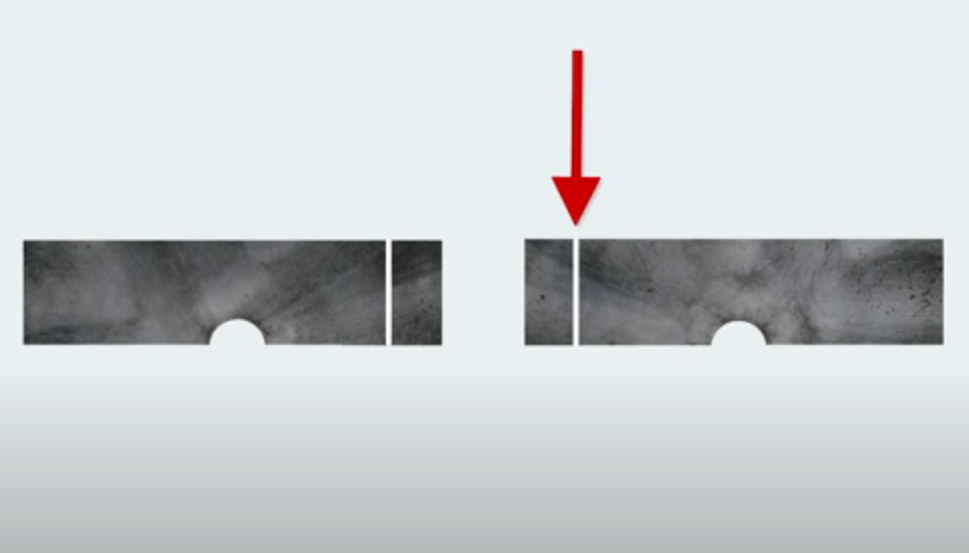

- now a working knife is made, which should be V-shaped - for this, two plates are cut from a circular disk;

- excess pieces are cut off from the plates;

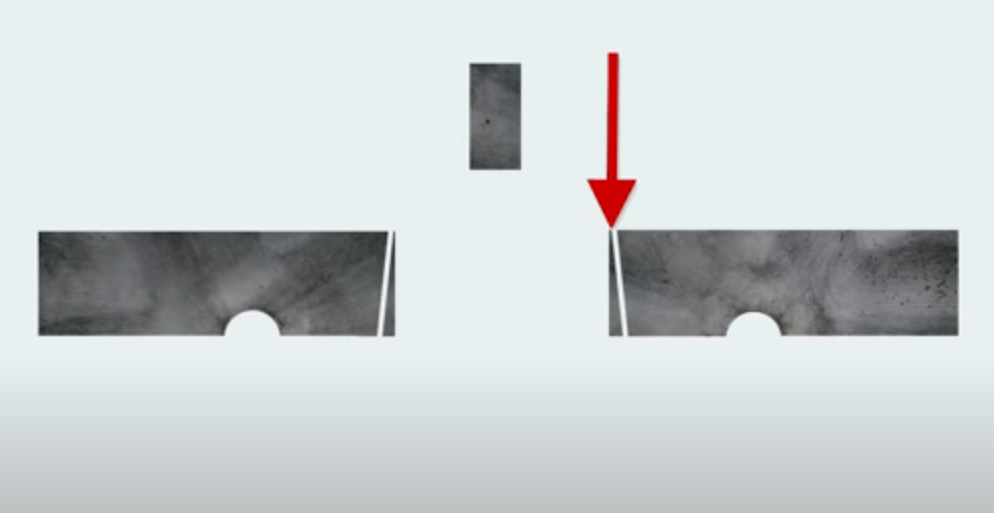

- then the edges of the prepared strips are cut at an angle;

- they are then welded to form a V-shape;

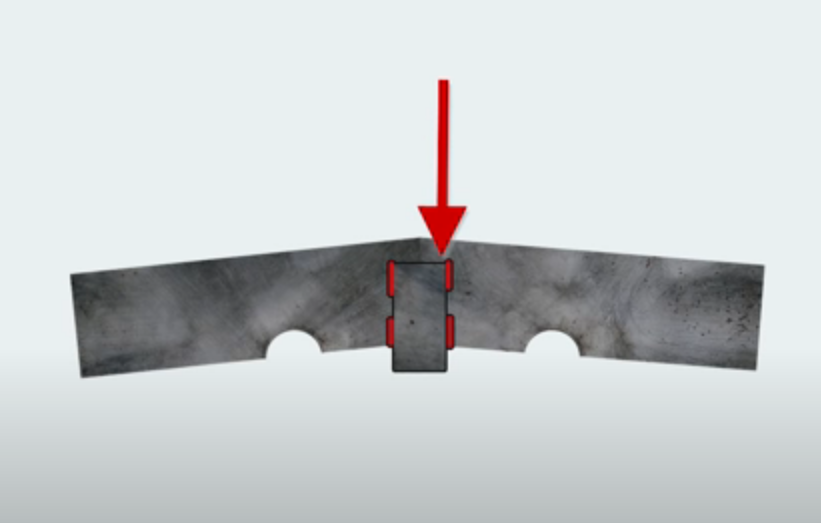

- their joint at the top is secured by a welded plate;

- the knife is sharpened on one side at the top;

- a frame in the shape of the letter P is fixed to the knife - on top it is made of a profile pipe, corners are placed along its edges;

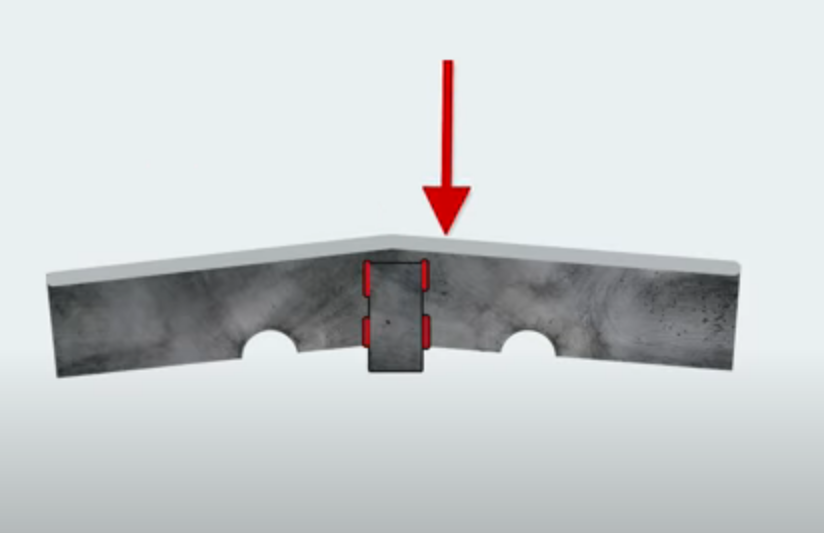

- the legs of the cutting element are made of a metal strip - this is necessary for fixing them to the corner using bolts;

During further operation, it will be possible to add holes to change the immersion of the bipod into the ground.

- the blade on the frame is positioned so that there is a slight downward slope of the nose - the final height of the bipod should be approximately 20 cm;

- The bipod is fixed to the fork maintaining a distance of 30 cm from the wheel axis.

The width of the bipod is adjustable so that you can work between rows without disturbing the stems. 24–25 cm is considered optimal. The distance between potato bushes is wider than that of other crops, so treatment with a cultivator will need to be done in two passes - first in one row, then moving to the second.