Sharpening a lawn mower blade

The blades of such a convenient device for any owner of a country house as a lawn mower are made of high-quality steel. However, their sharpening also has to be updated. Of course, you can also mow with a dull knife. But then cutting the grass will be rough, which will lead to its delamination and ruin the appearance of the lawn. You can do the sharpening yourself. We tell you how to do it correctly.

The content of the article

Preparing to sharpen lawn mower blades

Before removing an element that requires sharpening, you should protect yourself and the device itself. If this electrical equipment, then it will be enough to disable it. For a gasoline unit, you must first perform some steps:

- remove the cap from the spark plug;

- prevent leakage - you can turn off the fuel valve or drain the fuel;

- turn the device towards the handle (rarely, but the instructions may indicate a different action, then follow it);

- take care to block the rotation shaft - to do this, place a block resting on the ground under the blade;

- unscrew the fixing elements holding the knife counterclockwise.

If you cannot immediately release the cutter, you should soften the threaded connection so as not to damage the edges of the bolt or key. This can be done with oil or grease. Afterwards you need to wait a few hours.

Cleaning and straightening the blade yourself

The first stage is to remove adhering dirt and hardened plant juice. There is no need to clean so that the surface shines. It’s enough just to rid the blades of everything unnecessary.

When using the device, hard objects often get into the working area - stones, chips - which leads to deformation of the blade. To correct it, you need to use a hammer with slightly rounded edges of the striker.

The knife is placed on the anvil and with gentle blows the desired shape is achieved. It is necessary to edit from the edges of the bent part, carefully moving towards the center.

The process of removing descents

This is the name of the area on the knife blade - the boundary between the base of the working part and the surface of the tip. If the cutter has not been sharpened for a long time, chips appear on it. By bringing the edge of the blade at the same angle over its entire surface, you can get rid of any defects that have appeared. To do this, you need to take an electric sharpener or a small file. It is important that the metal is removed evenly from both blades. This can be achieved by applying equal effort and approximately counting the number of passes.

The more smoothly the triggers are pulled out, the longer the blade life will be.

Sharpening

This manipulation can be performed using an emery block with a grit rating of 400–600. During the process, the device should be periodically moistened in soapy water. The sharpening itself is carried out on the grain by pulling the bar from the center of the processed area to the edge.

To increase the productivity of the process, you should use a drill with an adapter. A sharpening device - a stone or a circle - should be attached to its chuck. After switching on, you need to start with the serrated tip.It is convenient if you can fix the drill and move the knife along the edge of the grinding wheel.

Do not apply excessive pressure during processing. Movements should be smooth. It is necessary to avoid overheating and try to keep the sharpening angle in one position.

Straightening edges

After sharpening, the blades require straightening or grinding. If this is not done, then due to the small burrs formed on the thinnest part of the blade, it may curl.

To do this you will need sandpaper. You can take a type with a grain size in the range from 600 to 800 grit. The sandpaper must be moisture-resistant, since before use it must be moistened and rolled into a small cylinder - a centimeter to one and a half in diameter. It should be slightly pressed against the surface of the thin part and carefully pulled out, moving from the center to the edges.

If the above manipulations - removing the slopes and subsequent sharpening - were carried out only on one side, then straightening the edges requires processing the back surface as well.

You can also carry out grinding using an emery machine. To do this, the sharpening stone is replaced with a felt wheel. A uniform layer of GOI paste is applied to it.

After turning on the engine, the sharpened element must be pressed against the felt and moved in any direction. It is necessary to ensure that the tip does not turn towards the fibers of the circle.

Do not allow the blade to overheat.

Balancing

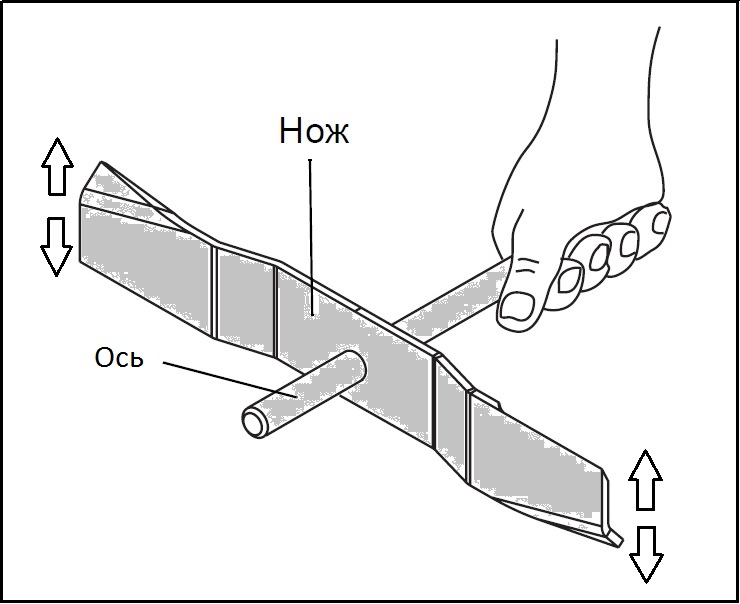

Before reinstalling the knife, make sure that its halves have identical weights. As a rule, double-sided single and compound cutters require balancing.

To check, the blade is placed on a rod or pin clamped in a vice and aligned horizontally. If it works and there is no advantage, the balance has been maintained.If there is a deviation, it is necessary to grind off a small amount of metal from the back of one of the halves.

If after processing the cutter was able to fix itself strictly horizontally for at least a few seconds, grinding off the excess is stopped. Now everything is ready - the blade can be returned to its place and you can start caring for the lawn.