DIY lawn mower

Every summer resident has to look at an overgrown area once every two weeks. Weeding it takes a lot of time. It’s good that back in 1832 the lawn mower was invented. Today such equipment can cost from 50 thousand rubles and more. For a person living on the average salary in Russia, a lawn mower is a rather expensive purchase. That is why now you can find a large number of ways to make it yourself using available materials, without wasting money.

The content of the article

DIY lawn mower engine

It can be taken from the following devices:

- old vacuum cleaner;

- washing machine;

- Bulgarian;

- drill;

- chainsaw.

An excellent option could be an electric motor, the power of which starts at 400 W. Although the optimal figure would be 600 W.

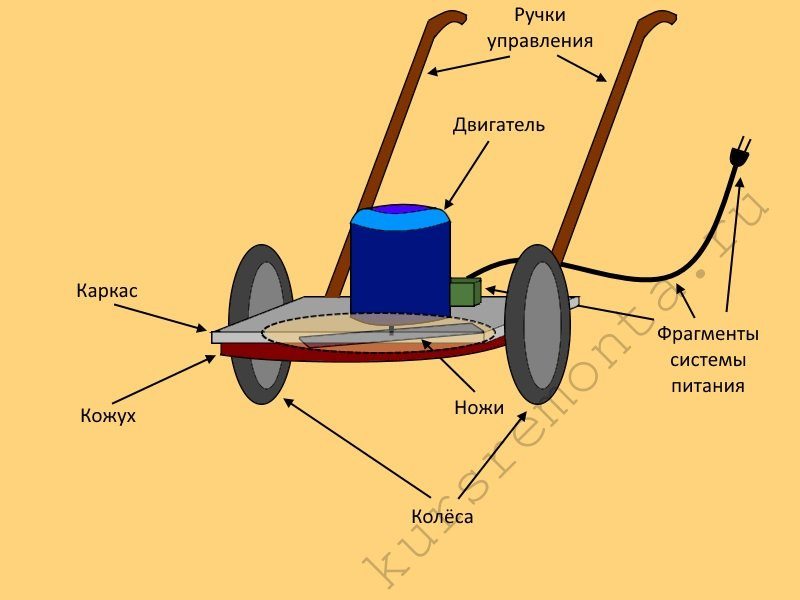

If you take a smaller one, you have to sharpen the knives quite often. A lawn mower must have at least 3 of them, which means that sharpening them takes up a lot of time that could be usefully spent. The engine must be asynchronous: its mechanism makes working with the unit less noisy. The engine should be mounted on the lawn mower shaft down - to twist the cutter.

Frame and assembly

Ordinary plywood with a thickness of at least 8–9 mm may also be suitable for the motor, but it is always better to use a sheet of metal with a thickness not less than 4 mm. Its size should not be large (40–55 cm). In the center of the sheet or plywood you need to drill a hole for the motor shaft to which the cutter will be attached.

The frame can be made from a part of an old stroller, cart, or you can weld it yourself using metal pipes. The casing must be high.

It is recommended to rid the iron of rust. A mechanical way to get rid of corrosion is with metal brushes. Chemical - using acetic, sulfuric, citric acid or a mixture of phosphoric and tartaric acids.

The wheels are metal, covered with rubber, diameter is 50–70 mm. If it is smaller, the wheels will be difficult to move, and the mechanism can easily break. If, on the contrary, it is larger, then the resistance of the grass will increase. It will stop cutting and will wrinkle. The number of wheels is four, but there are options with two, which, however, quickly break down.

It is recommended to install a switch on the case for comfortable operation, which will come in handy in case of an unforeseen situation.

The knives should be secured with bolts so that when moving they can move freely relative to the body, that is make the cutter prefabricated. This will help in case of a minor accident, which can be caused, for example, by a child's toy lying on the ground or a stone. The knife will not hit with all its might, which would lead to breakage. It will gently bend under the body and straighten after moving around the object during the operation of the electric motor.

Knives must be made of high quality steel, sharpened stronger further from the base.You need to work with them as carefully as possible for a visible result. The deck can be made from an old frying pan.

Near the knives, using a small concave sheet of metal, you need to build a protective bumper that will prevent grass from getting into the person.

It is recommended to make a collection bag so that most of the grass does not remain on the ground. It can be made of fabric, but in this case it will tear quickly, so it is better to make it from a hard material, such as plastic.

It is recommended to cover the body with protective paint or varnish: it will protect the device from rust and transform its appearance.

How the lawn mower works

It can be briefly represented by the following list of processes:

- Electric current is transmitted from the outlet to the switch.

- From the switch it moves along the wire to the electric motor.

- Electricity powers the shaft.

- The electric motor shaft begins to spin rapidly, spinning the cutter.

- The blades quickly cut the grass, and if they hit a heavy object, they bend inward without breaking the mechanism.

- The grass ends up in a collection bag, from where it can later be removed.

- If there is no bag, it falls into an iron bumper, which prevents it from getting into the eyes of the person using the device. In this case, the grass falls to the ground.

Lawn mower made from vacuum cleaner

When disassembling a vacuum cleaner from an electric motor, we need to remove the turbine: we no longer need it. Instead, we attach a cutter with knives. Then you need to connect the wire from the motor to the switch, and it to the outlet. For safety, you should use an RCD (residual current device).

It may have a high probability of failure, so it is better to consider the following options.For mobility of the unit, you can use a reel wire - one that will correspond to the power of the electric motor.

Washing machine based

Engines from washing machines are excellent in power for lawn mowers. We remind you: it is better to take an asynchronous one, because it will produce much less loud sounds.

The washing machine body can be used for a lawn mower without wasting time creating a new one. This is perhaps the main advantage when choosing this method.

Video

Based on the grinder

This option is one of the cheapest. We take the torsion disk from a circular saw so that the size matches the one required by the trimmer. You can replace the disk or change the diameter at any time. This is another advantage of this manufacturing method.

Chainsaw lawnmower

The frame should be welded from pieces of pipe. First we need to make a pipe telescopic shaft for the motor. We unscrew the tire from the chainsaw and “helm", take "asterisk" We place a piece of pipe with a circumference of 5 cm on it.

Before this, we take another piece with a diameter of 5.8 cm, and thread the first one inside it. For pipe fastening we use high strength M6 bolts, and they must be equipped with locknuts.

After this work, the cutter should be welded to the shaft, then as in the standard version.

Video: chainsaw mower

From a drill

Using it, you can make both a large lawn mower and a more compact trimmer with two wheels. The drill should be attached to the frame along with the handle, the wire is pulled through the handle of the frame and connected to the network.

It's best suited low speed drill. The motor, as in the case of the one that is recommended for use in a device made from a washing machine, must be asynchronous. The advantage is compactness, easy work in narrow spaces.

Rules for using a lawn mower

Recommended:

- Before turning on the device, be sure to check every one his detail. You should make sure that the wheels are screwed on, whether the knives are sharpened, and whether the bumper that protects from grass is not broken.

- Clean out excess trash from the work area.

- Warn and fence off people and animals from the effects of a lawn mower.

- Absolutely forbidden use it in areas with an angle of more than 20 degrees, on a wet lawn, during rain, in poor lighting.

- Smoking and open flames are prohibited. A person should not forget about overalls, shoes, and safety glasses.

- During long-term use, check the engine temperature as often as possible by placing your hand near it, but not touching it.

- Use RCD.

Remember: a lawn mower is a dangerous device, so use it wisely.