Do-it-yourself trimmer carburetor adjustment

Sometimes, for a device to work well, it does not require repairing a particular part, replacing it, or, worse, replacing the device itself. Sometimes it is enough to understand the principle of its operation and configure it correctly. For example, a lawn mower's carburetor can be adjusted to avoid high fuel consumption or more serious problems.

The content of the article

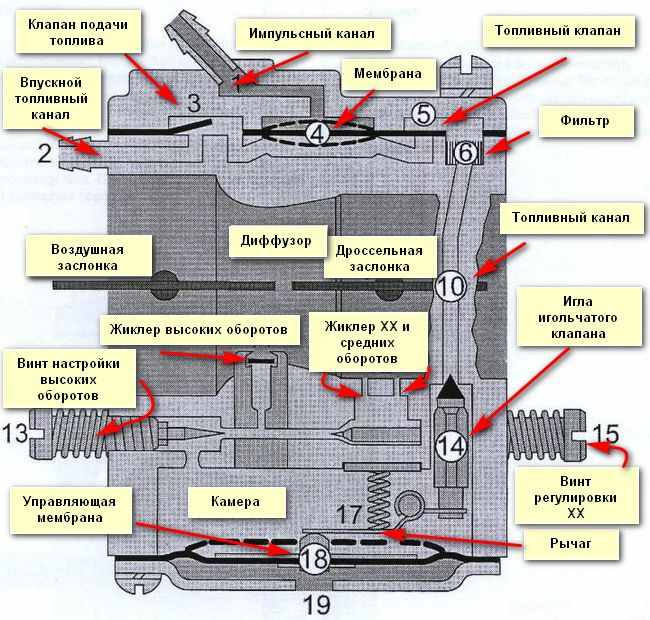

The structure of a lawn mower carburetor

A gasoline lawn mower, as the name suggests, is equipped with an internal combustion engine that uses gasoline as fuel. In order for it to burn internally, it requires air to form a reaction. The latter creates thermal energy, which then turns into mechanical energy.

A carburetor is used to supply fuel with air into the engine cylinder.

First, gasoline mixed with oil is transferred to the float chamber. There it continues its flow further, but when the required level is filled with fuel, the float rises, closing the fuel supply valve. The jet is a plug that prevents fuel from leaking out of the float chamber.

Gasoline passes into the mixing chamber, from above which air is supplied. The throttle blocks the access of fuel to enter the cylinder.When you press the mower pedal, it opens, fuel is supplied inside, and the internal combustion engine picks up speed. The maximum throttle valve can rotate up to an angle of 90 degrees, which depends on the force of pressing the gas pedal. A vacuum is formed in the mixing chamber, a strong air flow mixes with the fuel and transfers it into the cylinder.

At low speeds, an idle system is used, in which the throttle does not open completely, but partially.

The carburetor filter cleans the fuel from dust and other small elements, protecting the jets from their harmful effects. If they are clogged, the engine power will noticeably decrease.

The carburetor's job is to quickly direct fuel to the cylinder using air and mix it with oxygen, which allows the gasoline to burn. The difference between a car carburetor and a trimmer is only the presence of a membrane in the latter, which is used to suck gasoline from the tank.

How to understand that a lawn mower's carburetor needs adjustment

The following signs may indicate this:

- Difficulty starting the engine, low speed.

- Increased fuel consumption.

- The engine is unstable and the speed fluctuates frequently.

- There is a large amount of exhaust gases.

Checking the spark plug will help determine whether the carburetor is adjusted correctly. First, we free it from the casing and disconnect the contacts from the igniter.

We clean the spark plug socket with a device that pumps air. A compressor with a small tube is ideal for this purpose. Using a torque wrench, remove the spark plug.

Afterwards, pour solvent into the spark plug socket to flush the threads, and after a short period of time, unscrew the spark plug completely. If the electrodes are black, then this is carbon deposits that are associated with poor carburetor adjustment. If it is brick-colored, then everything should be fine with the lawn mower.

After a long period of inactivity, the tool also needs to be adjusted. For example, after winter.

It is also recommended to carry out adjustments when changing the composition of the fuel mixture: oil or gasoline.

How to adjust a lawn mower carburetor with your own hands

First you need to prepare:

- Flushing the engine can be done by draining the old oil and replacing it with new one, but with a high base number, the ideal is a diesel version. You can also use mineral. You need to work with it for some time and the internal combustion engine should clean up. If this option is not suitable, you can use a heavier and more expensive one. Remove the unit and wash it with a high pressure washer. We completely disassemble it and place it piece by piece in a bath of chemicals.

- Then you need to pull out the candle using the method described above, replace it with a new one. It is worth considering the spark plug as a consumable item that needs to be replaced in case of malfunction.

- Next you need to check how well the carburetor is attached to the cylinder-piston group.

- The next step is cleaning the air filter. To do this, you just need to blow it with compressed air, the best way is with a compressor.

- Cutting knives or a reel are mounted in the spindle.

- The adjustment springs are checked. They may be too tight and thick, which prevents precise carburetor adjustment. If this is the case, then it simply won’t be possible to configure it normally. To solve this problem, you need to purchase a new spring and insert it in place of the previous one.

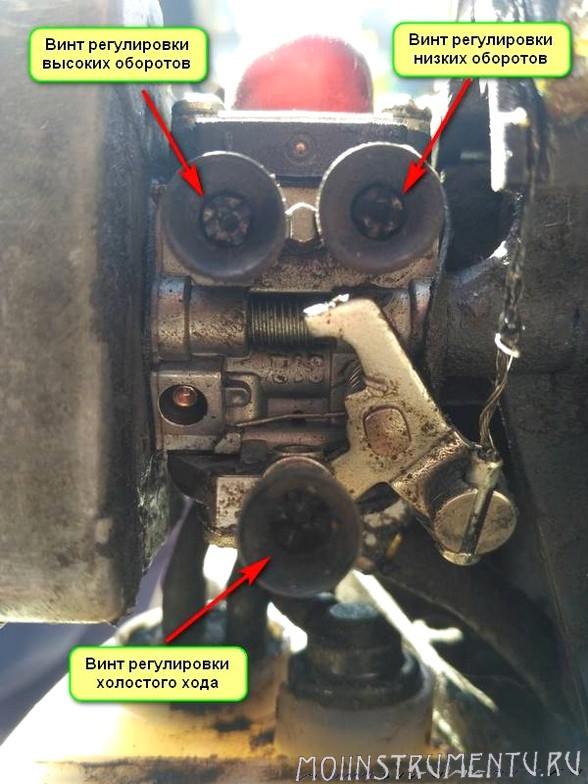

Adjustment

Sequencing:

- Let's start the engine. When running it on XX knives should not rotate, if the opposite happens, then we reduce the idle speed.

- We regulate screw L. It is responsible for the mixture at low speeds. First, scroll all the way clockwise, then unscrew it 90 degrees counterclockwise. If dips are found, we repeat this action, weakening it by 1/8, that is, by 45 degrees.

- We regulate LA screw, the more common name is T. As the XX rpm increases, more air is added to the mixture. Power is lost. But if there is not enough air, the fuel burns worse. We unscrew the screw so that it works perfectly at low speeds, while knives should not rotate. During the tuning process, you need to feel the speed, it should work stably at XX.

- We regulate screw H, which adjusts the mixture at high speeds. To identify their maximum number, we use a tachometer. When the maximum number of revolutions of the internal combustion engine is reached, unscrew the screw to the left 180 degrees, the adjustment is complete.

Sometimes only correct setting and using the device reveals its full potential. There is no need to neglect it and carry it out as needed.