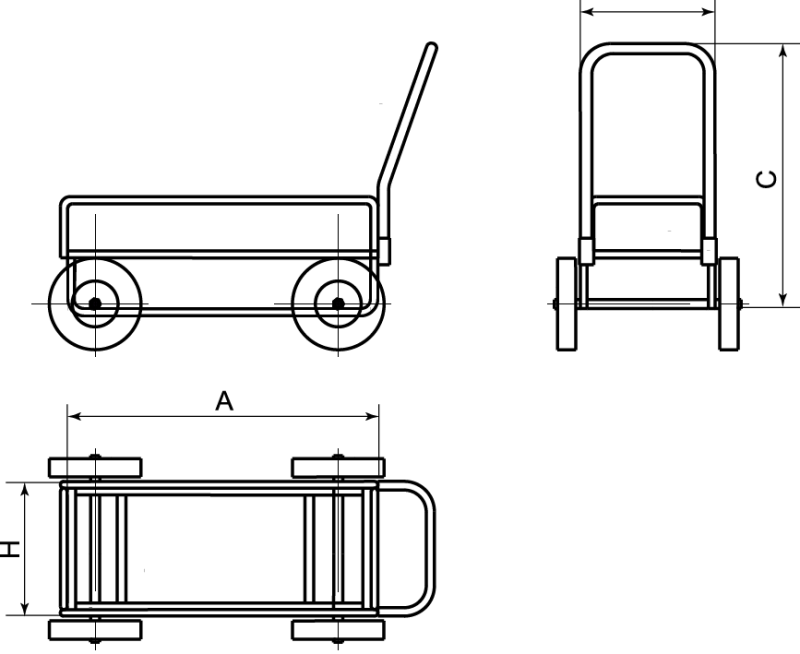

DIY 4-wheel garden cart

For the owner of a private house or cottage, the cart is the first assistant. It is used to transport various goods, which saves effort and time. The device has a simple design, differing only in the material of manufacture and the number of wheels.

Many craftsmen undertake to make such a garden device with their own hands. Let's figure out how to make a four-wheeled cart and find out what common features such devices have.

The content of the article

Main design elements

As already mentioned, there are different models of wheelbarrows, each of which has its own peculiarities. However, all devices have the following basic elements:

- Frame. It is made from a corner, a profile - square or round. The advantage of the last two options is the ability to withstand heavy loads. Some craftsmen do not weld the frame, but attach the wheels with a handle directly to the body.

- Body. To independently produce this element, pieces of sheet metal are cut out and welded. For better joining, a metal corner is used - it is placed on the ends of the product.

- Wheels. Different ones can be used, but the most convenient ones are chamber ones. A garden cart with them moves very easily around the site. Craftsmen use wheels from a bicycle, moped or motorcycle to make them. You can also buy ready-made copies in stores - there are ones specifically for wheelbarrows.

- Lever. May be different in shape.The most common ones are in the form of the letter “P”, “T” or “N”.

Manufacturing recommendations, tools

Before you start assembling the cart yourself, you should consider the following tips:

- It is better to make production according to a drawing - you can find and use a ready-made one or slightly modify it depending on your own preferences;

- It is worth deciding in advance on the volume of the body - you need to focus on what and in what quantity you often have to transport;

- the upper edge of the sheet steel used for production should be edged to prevent accidental cuts;

- the profile pipe from which the frame is made must remain end-to-end or welded tightly - this will prevent water stagnation;

- it is important to make an accurate calculation of the position of the wheel axle to evenly distribute the load;

- It will be more convenient to use if you put rubber on the edges of the handle;

- It is advisable that a stop be provided on the back of the device.

To construct a wheelbarrow from metal, you definitely need to take a welding machine, an angle grinder, and a set of metalworking tools.

Manufacturing process

The sequence of actions for creating a garden device on four wheels for transportation looks like this:

- the frame is welded;

- the body is being constructed;

- a handle is made;

- wheels are attached.

Now in more detail about each stage. The frame structure is made from a profile pipe. Welding is used for its manufacture. To ensure greater reliability along the length of the product, the product is equipped with jumpers - they will serve as stiffening ribs.

Now the body of the 4-wheeled trolley is being constructed. Some improvised devices can be used for it, for example, a steel trough or half a metal barrel.

The body is made from scratch. To do this, vertical posts are welded at the corners of the frame, and metal walls are attached to them on the outside. Inside there is a base or bottom. For the walls and bottom, it is optimal to use a steel sheet with a thickness of 2–3 mm.

To make a handle, take a pipe with thin walls. All that remains is to install the wheels, and the device for transporting goods is ready.

It should be noted that the use of pneumatic tires will increase the weight of the transported cargo. The device can be painted or treated with a special compound.