Do-it-yourself watering nozzle for a hose

The easiest way to water various plantings on the site is with a hose. However, the hydraulic hose itself is not entirely convenient. In most cases, it is difficult, if not impossible, to do without a special nozzle. These hose attachments often break. Craftsmen offer ways to make them yourself. We talk about two options for making homemade watering equipment.

The content of the article

Hose nozzle made from sanitary waste

This homemade product consists of:

- from two pieces of propylene pipe, which can always be found after repair;

- couplings made of the same material, equipped with metal threads on the outside;

- valve;

- shower head.

You should start by cutting threads on the pipes. The diameter should be 2 cm. This size is optimal for a 0.5 inch die. This process should be carried out by first clamping one end of the plastic in a vice. On the other, you can conveniently cut threads - the die will ideally perform this stage of the work.

Next, the threaded blanks are screwed into the valve on both sides. They are screwed in with tension, so the tightness of the structure will be ensured even without the use of FUM tape.

A ball valve equipped with a long handle is ideal. It will be easy for her to adjust the necessary pressure water.

The next stage is welding a coupling equipped with a metal thread on the outside to the pipe. The watering can is screwed onto the latter.

Build process

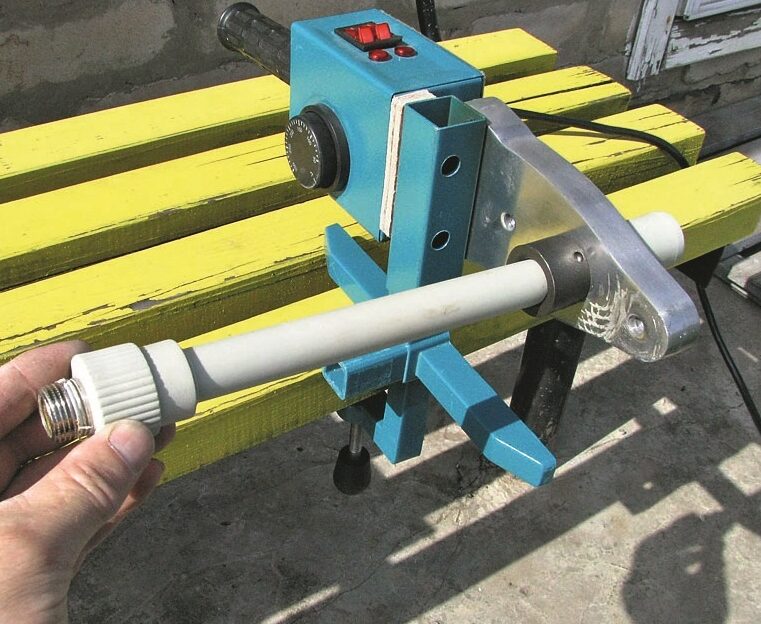

To connect polypropylene products, special equipment for welding plastic is used. The pipe is inserted on one side into the heated nozzle of the device, and on the other, a suitable fitting is put on. After five seconds, both parts are removed and connected. After the plastic cools, which occurs quite quickly, a perfectly sealed and durable connection is obtained.

A watering can is screwed onto the coupling thread. It should be without a handle and with a 0.5 inch thread inside. PVC electrical tape is wound onto the pipe on the other side of the nozzle. This will make the connection to the hose more reliable. The hose is put on the thickening and secured with a clamp.

That's it - the nozzle is ready! It is quite reliable, not afraid of shocks and allows you to properly regulate the pressure.

Similar nozzles can be made in different sizes. The long ones make it possible to conveniently water plants right to the roots - no need to bend over too much.

Homemade hose sprayer for circular watering

The homemade product, the manufacturing process of which will be described below, can be adjusted to different pressures. It will be able to spray water over a distance of up to four meters in a circle. In addition, it is many times more durable than its Chinese plastic counterparts.

Needed:

- profile pipe 20*20 mm square section;

- a piece of 0.5 inch round pipe;

- angle grinder;

- electric drill or screwdriver.

First of all, you need to make a section of profile pipe approximately 6 cm long. Next, it should be sanded.

Further actions:

- a piece of half-inch pipe is welded to the prepared profile pipe;

- a plug is placed at the other end - it can be a metal plate or a wooden chopper;

- a through hole is made in the center of the profile pipe - its diameter should be 5 mm;

- on one side this hole is drilled to a diameter of 1 cm;

- a thread is cut in a small hole and a bolt is screwed in;

- a nut is welded on the other side.

This process can be clearly seen in the video.