How to connect watering hoses

To connect hoses used for watering the garden or other household needs, both ready-made store-bought and improvised devices are used. Options are selected depending on the material, diameter and conditions of use of the products.

The content of the article

Types of connection fittings

The hose connector is designed to facilitate gardening work and ensure quality garden care. The device is needed to firmly connect two products into a single structure. Let's look at ways to do this.

Fittings

For connecting hoses, the simplest element is considered to be a fitting. The device is shaped like a bolt. It is hollow and has herringbone-shaped fins on the outside. It creates resistance for a secure hold. Clamps serve for additional fixation.

The fitting in the protruding part has a larger diameter. This feature serves as a limiter and for connection to another fitting. The hoses are put on both ends of the connector and secured with clamps. Devices can be made of metal or plastic.

A variation of this connection is adapters. They are designed for hoses of different diameters.

Docking with fittings is suitable for products made of rubber, silicone, PVC, TPE, corrugated.

Couplings

These devices can be of several types.

To connect products of the same size, the easiest way is to use a repair coupling. You need to purchase a device of the same diameter. The process looks like this:

- both nuts are unscrewed from the coupling;

- nuts are put on the hoses;

- the hoses are inserted one by one into the coupling;

- the nuts are screwed onto the coupling.

The nuts, thanks to the cone-shaped inner surface, compress the coupling petals during the screwing process. The latter clamp the ends of the hoses. A reliable connection is ensured - a collet clamp.

Universal repair couplings are produced. They are suitable for connecting irrigation products of different sizes.

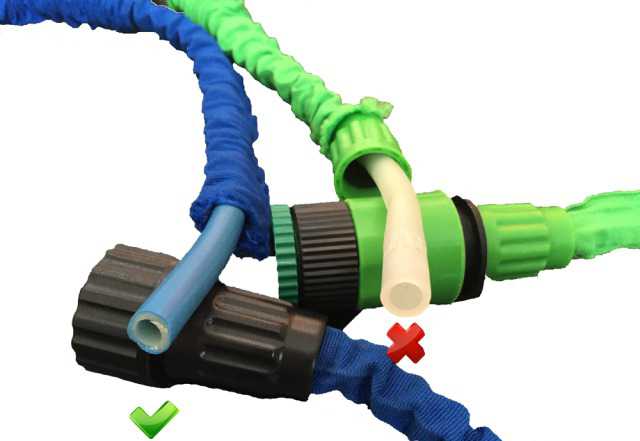

The so-called The quick-release connection is made using two couplings and an adapter. The coupling has a collet clamp on one side - it performs the function of fixing the hose, and on the other there is a spring fastening. The latter, when putting the coupling on the adapter during the joining process, snaps onto the protrusion. To do this you need to press until it clicks.

The joint is sealed using rubber rings on the connectors. To disconnect, you need to move the ring in the direction of the hose. After this, the clamps will be released from the hook and the coupling can be easily removed from the adapter.

Quick-release connections can be in the form of a tee, herringbone or cross.

An improved type of coupling is aquastop. They are equipped with a valve that prevents water from leaking out when disconnected. The best option for connecting to systems under constant pressure.

How to connect hoses with your own hands using improvised elements

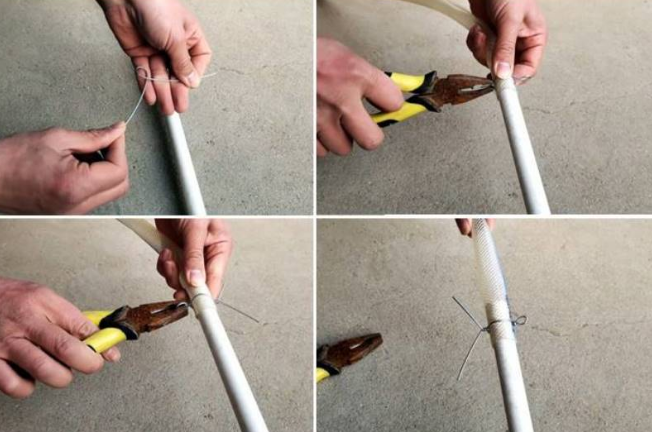

A homemade fitting can be made from a piece of polypropylene pipe of suitable diameter. The role of a clamp can be performed by a steel tie wire 1–3 mm thick. If you can make a twist with a loop out of it (see photo), then you can tighten it on both sides.

To join corrugated products without any fittings, you need to do the following:

- cut their ends so that one has a depression and the other has a protrusion;

- slightly cut the end part transversely to the tube;

- screw the ends into each other as if threaded;

- tightly wrap the joint area with tape.

These options and methods of connecting hoses will help you choose the right one for a specific task.