DIY pruner repair

Garden pruners, like any tool, can sooner or later fail. The reasons for this are simple non-compliance with operating recommendations or poor quality of manufacturing materials. Let's figure out what can be done if the pruning shears break.

The content of the article

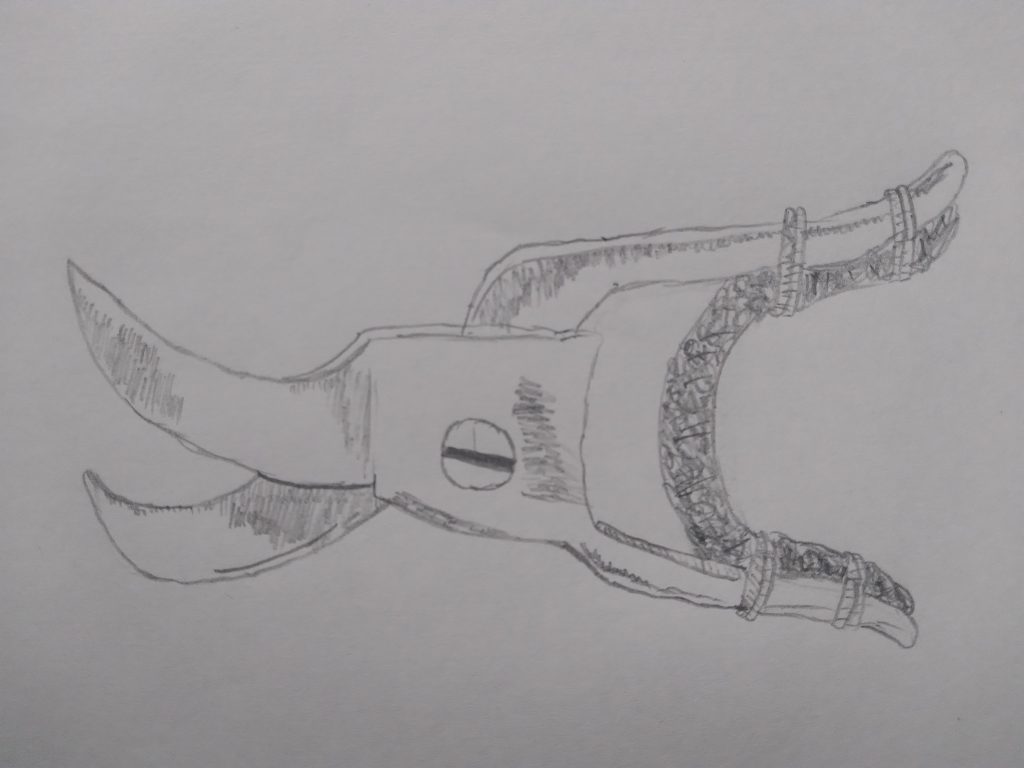

A little about the design of the tool

Conventionally, all devices for trimming vegetation on a site can be divided into conventional and more advanced. Their difference is a different implementation of auto-unclosing of the working blades. In conventional tools, a spring is responsible for this, and in newer models - ratchet mechanism. If the latter is present, there is no need to apply great physical force to “bite through” thick branches. This is the main advantage of such a tool.

Repairing the spring of a conventional pruner

The problem with this particular element usually happens quite often. If there is something to replace the part with, then the repair is simple. You need to disconnect and remove the “original” spring and replace it with another, more or less suitable one. Only a part that has sufficient rigidity will be suitable, which will not allow the handles to dangle.

It is necessary to firmly secure the new element in the mouths of the handles. Sufficiently wide aluminum plates can be used for fixation. The ends of the spring will be located under them.The plates themselves should be wrapped and, as it were, riveted around the handles.

A regular hose can replace a failed spring. It should be thick-walled and elastic. You need to cut a piece equal in size to the spring being replaced and insert it in its place. For more “serious” repairs, you will need a longer piece - approximately two lengths of the tool handles. We place it on the inside of the handles and secure it with electrical tape or tape.

Repair of tools equipped with a ratchet mechanism

The following types of breakdowns occur most often:

- failure of the latch;

- problems with the release mechanism;

- chip formation;

- misalignment of knives.

All of the above problems can be easily resolved on your own.

A broken instrument must not be used. This is inconvenient and unsafe.

If the release mechanism fails, the problem can only be solved by replacing it. Let's consider what to do with the other faults mentioned.

If the latch is broken

The solution to the problem depends on the element type. If the latter is located on the handle, then you can glue the plastic retainer using a heat gun.

If the plastic element is lost, then you need to make a wire ring at the end of the handle. It will help to squeeze the handles. It is better to fill the location of the fixing element with glue from a hot-melt gun. This is necessary so that the latch does not move on its own during the process of trimming branches and does not jam.

If there are no holes for attaching the wire, they can be made with a drill. Another option is to make a bracket. It should be in the form of a plate with a hole. It should be attached to the handle using electrical tape.

Skewed knives

Such a nuisance leads to a decrease in the quality of the cut.In addition, the operation of such a tool is simply inconvenient.

Attention! The malfunction should not be corrected by bending the support blade. Such actions will make the problem worse.

The correct and only solution is sanding. This must be done until the convergence of the knives becomes uniform.

Chip formation

Only grinding the surface of the cutting part with emery until the defect is completely eliminated will help solve such a problem.

Even more about repairing pruners in the video.

You should purchase only high-quality tools, use them correctly and maintain them regularly. Then its operation will be long and problem-free.