DIY rake-tedder

The use of tedder rakes greatly facilitates the hard work of the farmer. This attachment shows quite high efficiency in hay harvesting. However, it is expensive. Craftsmen offer options for making it yourself.

The content of the article

Types of tedder rake designs

There are several of them, but the most popular are rotary and wheel-mounted. The first is a finger design. It is based on horizontal rotors. That is, the composition includes rotating parts of the engine, onto which the beams are fixed by means of springs. The latter are used for raking hay.

Another type is also called “sun”. Its peculiarity is the presence of three to five wheels located obliquely from each other. This design allows for increased work efficiency. And the simple fastening - each agitator is mounted on two bearings - facilitates the repair process, which is also important. In addition, this type of rake is the easiest to make yourself.

Rake-tedder: DIY manufacturing process

First you need to make a frame. The basis for it will be metal pipe. It can be round or square. A good option is a frame from an old motorcycle. It is also necessary to prepare:

- wire for raking elements - a product with a thickness of 4 to 8 mm is ideal;

- steel sheets (4 mm) - wheel rims will be made from them;

- brackets for fixing wheels;

- two bearings for placement in the hubs;

- parts for assembling the attachment, which is necessary for attaching to the equipment.

If you need to make a homemade rake for smaller equipment - a walk-behind tractor - then you should choose the option with three wheels. For a mini-tractor, it is recommended to increase their number to five.

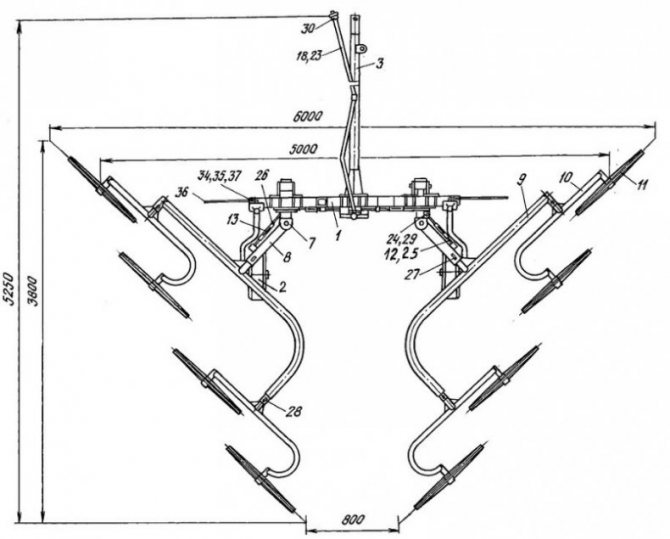

To help the craftsman, the following diagram:

If the frame is made of a metal pipe, then using a grinder and welding, cutting and fastening of parts is carried out. Further:

- brackets intended for wheels are fixed to the formed main frame of the device;

- the wheels are made of prepared steel disks (frames from bicycle wheels can be used, but they additionally need to be reinforced with metal rods and overlays);

- raking elements are made from wire, and in order for them to be replaceable, it is necessary to provide clamping mechanisms or bolted fastenings;

- To mount each wheel, two bearings are used - they are placed in the hubs (the latter are best taken from the classic VAZ model, where the bearings are tapered).

All that remains is to mount the attachment for docking with the vehicle. It needs to provide shock absorption (steel springs are suitable for this) and a special lifting mechanism. The latter’s task is to lift the tedders off the ground in the right places and return them to their original position when the vehicle takes a certain position.