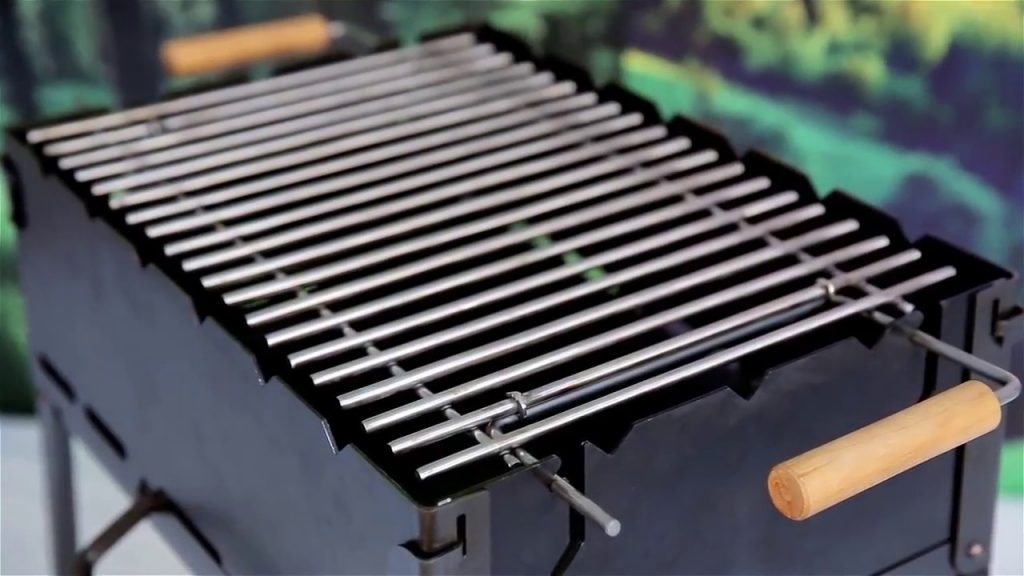

DIY barbecue grill

Those who like to cook food over a fire acquire various devices for this. One of them - B-B-Q. You can buy it or make it yourself. Cooking in such an oven is not complete without the use of various accessories. One of them is the grate on which food is placed. This cooking method allows the heat from the fire to be evenly distributed over the entire surface. You can make this barbecue accessory yourself.

The content of the article

Selecting grating material

The manufacturing materials for store-bought versions can be iron, stainless steel and cast iron. Each of them has pros and cons:

- iron is the most affordable, durable, but over time it burns out and becomes rusty and requires careful maintenance;

- stainless steel - a product made from it is lightweight, resistant to high temperatures, does not corrode, and is easy to clean;

- Cast iron is heavy and durable, does not burn out, and food does not burn on it.

What material to choose for a homemade grill so that it is practical and useful? The following mistakes should not be made:

- you cannot take an unknown metal - you cannot make a mesh from whatever comes to hand;

- use light alloys;

- use thin wire.

A grate made of high-quality material will last a long time.

The ideal choice for a homemade accessory would be stainless steel wire 3–5 mm thick. You can buy it at the construction market or in a store.

The outline of the future product is made either from steel of a larger diameter or from a stainless frame. Since the rest of the rods are attached to it, it must be rigid and durable.

Reference. It is not recommended to use different metals to make the frame and rods.

Cast iron is a good choice for a homemade grate. It will be strong, heavy and durable. To make such a barbecue accessory, solid rods made of this alloy or old grates from stoves are suitable, from which you can cut out the necessary elements.

Barbecue grill manufacturing process

Having decided on the material, it is worth choosing the shape and dimensions of the future product. Then prepare the rods, mount the frame, and secure the handle.

The step-by-step process looks like this:

- We choose the shape and determine the required dimensions. The most common is the rectangular accessory. As a rule, the optimal dimensions of a barbecue grill are 35*26*2 cm. This area can accommodate 1.5–2 kg of meat. If you need a surface for large portions (3–3.5 kg), then you should double the length and height - 70 and 4 cm, respectively. The width of the product should then be 45 cm.

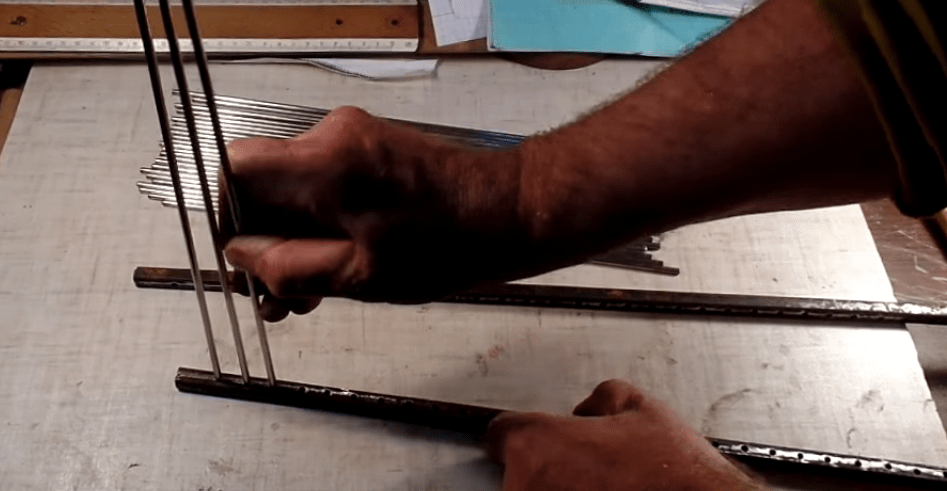

- We prepare the longitudinal parts of the frame. To do this, take two rods made of ordinary steel 8 mm thick and measure the required length. We make marks for the holes every 1.5 cm. This is the optimal distance at which you can cook both large and small pieces. Using a punch and a hammer, we make small notches along the serifs. We drill holes in them with a 5 mm drill.

- We assemble the grid. We take rods made of thinner stainless steel. The diameter of the elements is 5 mm. We make them to the required length. We clean the cut corners. We insert them into the holes on the longitudinal parts.When finished, level with a hammer. We fix the thin rods to the longitudinal ones by welding.

- We make and attach the handle. It’s easier to use a store-bought one - it’s inexpensive. You can weld two handles on both sides.

Creation of a grate gratings made of cast iron will require forging skills. This is a complex and time-consuming process. A cast iron grate cannot be made using conventional electric welding. The material melts at lower temperatures, so special electrodes with graphite should be used. In addition, you need to remember that rapid cooling of the weld is inadmissible. Cast iron is a brittle material and can crack.