DIY barbecue made of metal

You can build a barbecue oven yourself from scrap materials. The reliable design is made of metal. You need to find a suitable material and follow the manufacturing instructions.

The content of the article

Requirements for the metal structure of a barbecue roaster

To make the stove reliable, you need to know what needs to be taken into account at the initial stage. The following requirements must be met:

- BBQ Feature — presence of an open type camera. Because of this, special chimneys are rarely used to get rid of combustion products. But if you plan to add a hood to the product, it is necessary to provide for attaching the fryer to the base to add stability to it.

- The thickness of the selected metal should be at least 1.5–2 mm. Otherwise, the material will quickly become unusable due to constant heating.

- When choosing a suitable model for building a barbecue, you should consider how the temperature and smoldering of the coals will be maintained so that the process is as efficient as possible.

It is not recommended to overload the product with a large number of different decorative metal elements. This will add to the difficulty of cleaning the barbecue.

Types of structures

The fryer can have a different design.To choose the most convenient and suitable option, you should learn about the features of each type:

- Disposable. It is created from scrap parts - even tin cans can be used. It is built for one-time cooking.

- Stationary. It is stable, simple and economical. Sometimes it is supplemented with a lid or hood. Can be used both in open space and under a canopy.

- Collapsible. If in the previous version all elements are welded to each other, then in this case the parts are screwed with bolts. Therefore, it can be assembled and disassembled if necessary.

- Folding. The advantage of this option is mobility. It is folded and transported in the trunk. It looks like a suitcase, but it can be difficult to build such an option yourself.

It is recommended to choose a suitable design taking into account the area of the site and the characteristics of use.

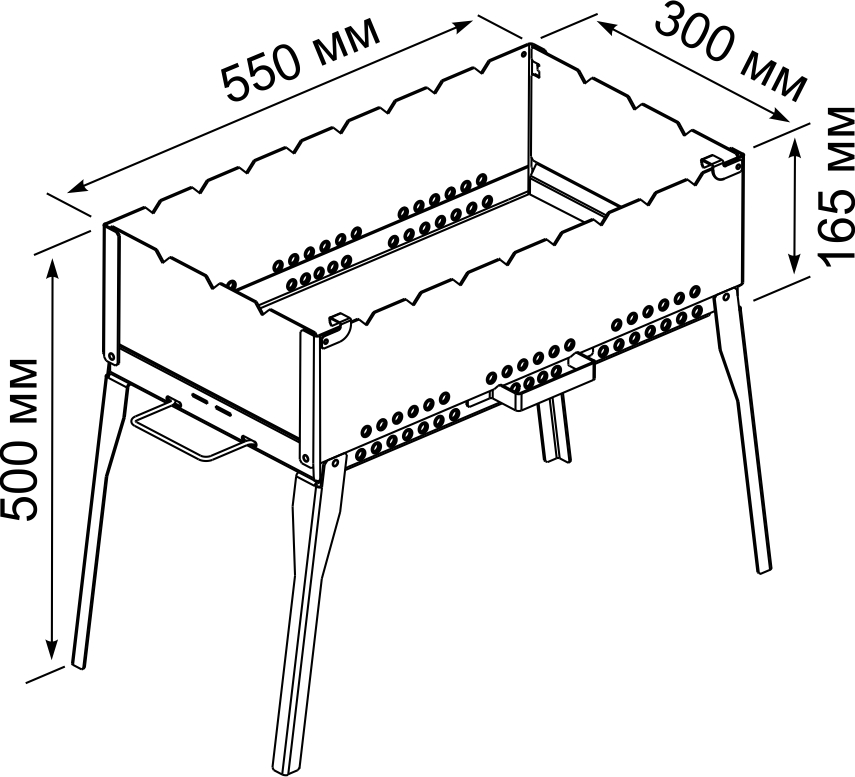

Drawings and dimensions

For convenience, you need to create a small project - a drawing of the future barbecue. This will allow you to take into account all the nuances and decide on the size. You can use a whole metal sheet or pieces. In the latter case, it is convenient to make a prefabricated structure when the bottom is thicker than the walls.

Profile pipes are suitable for constructing legs on which the product will stand. You can use metal corners.

The width of the box should correspond to the length of the skewers, from which about 10 cm is subtracted. The average value is 30 cm. The length is affected by the number of skewers that are planned to be used on the grill at the same time. The depth of the structure is 20–25 cm. Increasing this parameter will lead to higher fuel consumption and slower cooking of food.

The bottom of the barbecue is made double, which allows you to maintain stable heat of the fire layer without the risk of spilling coals.

Step-by-step manufacturing instructions

The process of building a barbecue with your own hands consists of the following steps:

- Marking. On a metal sheet it is necessary to draw the parts of the barbecue in disassembled form.

- Cutting out the resulting workpiece. A grinder is used. The sides are welded to each other. It turns out to be a box.

- Attachments for supports are welded in the corners of the bottom. It itself is made solid - without holes. A perforated part is placed on the bottom - a false bottom. Air enters through the side slot and holes in the perforated part.

- Grooving. Necessary for fixing skewers to the structure. They are made at the top of the long side elements.

- The legs are made and attached to the grill. This is the final stage of work.

It is not difficult to make such a stove with your own hands. This type is stationary. You can add handles or wheels to it to make it easier to move from one place to another.

You can also build a collapsible version of the barbecue yourself. The scheme of actions is similar to the previous one:

- Markings are applied to the metal sheet. It is important to leave a small allowance on each side.

- The walls and bottom are cut out along the drawn lines.

- Make holes for ventilation. On the left allowances, holes are made through which the elements will be attached to each other. Instead of welding, bolts are used to connect parts.

- The legs can also be attached rather than welded. The structure is ready. If necessary, it is disassembled and moved to another place, removed into the house.

Tips for use

In addition to the correct manufacturing of the structure, it is important to use it correctly so that it lasts longer and the dishes turn out delicious. After constructing the brazier, it is thoroughly cleaned of rust and dirt. In addition to standard napkins, they use a grinding machine: it perfectly removes traces of rust.

There is no need to thoroughly remove carbon deposits after cooking. A small amount will give the dish a special aroma. If you plan to paint the finished structure, you should use only products that are resistant to high temperatures.

The surface should be degreased and the structural parts should be soaked in caustic alkali for about 90 minutes. This will avoid corrosion and create a heat-protective film on the structure.

If the barbecue contains wood elements, they must be treated with moisture-resistant compounds and antiseptics. There should be no dry grass or branches at the location of the brazier. It is prepared in advance before installing the structure.

Making a barbecue from a metal sheet is not that difficult. All you need to do is select the appropriate material and follow the instructions.