DIY brick barbecue

A stone barbecue oven on the site is a beautiful and original element of the recreation area. It can be located either in a gazebo or in the open air, be an integral structure or part of a kitchen complex. How to post it yourself brick oven with our own hands - we’ll find out further.

The content of the article

General design requirements

A barbecue can be equipped with two or more fireboxes, which makes it multifunctional and practical. Sometimes a smokehouse, stove or even oven is installed in it.

Any barbecue oven has a grate and a roasting pan. The gratings should fall twenty centimeters below the edge of the walls.

The tray may not have holes, resulting in an even draft that allows food to cook evenly. The walls should always be high, so the food comes out smoky.

What is needed for construction

Before starting work, you need to prepare:

- a small amount of concrete;

- unedged boards for the frame;

- iron reinforcement for laying the foundation slab;

- edged boards;

- material for waterproofing (roofing felt, etc.);

- metal pipe with a diameter of 15 cm.

How much material is required depends on the size of the future structure.

Making a barbecue oven

Construction of a furnace is a labor-intensive process that takes from 4 to 7 days. By adhering to all the rules of construction, you will be able to make it not only beautiful, but also durable.

Foundation

A strong and reliable foundation plays an important role in any structure. The ideal option for this is to use a slab, which is excellent for weak and floodable soils. It may seem that pouring such a slab requires a lot of concrete. However, in this case this is not the case.

Even during design, it is necessary to calculate the excavation depth and the thickness of the slab so that the latter protrudes above the surface by about half a meter. If you plan to build an oversized stove, then the thickness of the slab is approximately 10 cm.

For functional large complexes, this parameter should be increased to 15 cm. The foundation is laid in several stages:

- In the chosen location, a hole up to half a meter deep is prepared, and the bottom is leveled and compacted.

- Formwork is installed from prepared edged boards, and a mixture of crushed stone and sand no more than 20 centimeters thick is poured.

- This mixture is poured with water and compacted, and a separating layer of waterproofing material (most often roofing felt) is covered.

- The reinforcing mesh is laid, but it should not reach the formwork by 3–5 centimeters.

Now you can prepare the concrete and make the foundation. You need to fill it in one day to avoid the formation of “cold seams”. During work, it must be compacted to expel all excess air. For this, a crowbar is used so as not to disturb the reinforcing mesh.

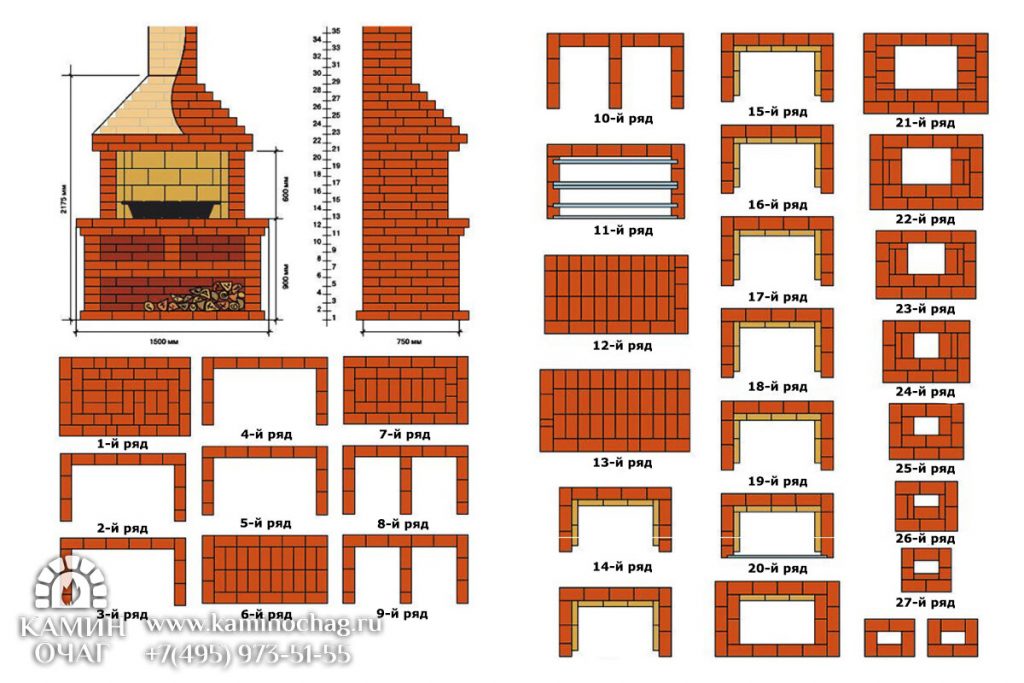

Brick laying, ordering

The foundation will finally harden in 3–4 days. Afterwards, roofing material is laid on it. This material, laid in two layers, will protect the furnace walls from moisture and water from the ground.

Afterwards, you should choose what openings there will be, as well as lintels for them. For standard rectangular ones, a regular iron corner is often used.If the openings are in the shape of an arch, you need to create a template in advance, according to which the vault will be built in the future. After this, masonry work begins, taking place in several stages.

Initially, the lower tier is laid out. The walls are built in half a brick, leaving openings. Their height should be 60–80 cm - the most practical option and suitable for almost any height. If necessary, the height can be increased at will.

Important! If you are planning a building with a sink, then when laying the walls you need to install not only a pipe, but also run water hoses through it.

The top row is made with a slight protrusion outward, which will allow you to install the formwork for pouring the screed. To ensure a high-quality and durable design, you should adhere to several important recommendations:

- the seams must be made the same size;

- the height of the openings is calculated so that at least two more rows of bricks can be placed between the table and their upper edge;

- The arched opening is additionally decorated with one brick in the center.

The concrete frame must be laid on a pre-designed step inside the oven. The base for the firebox and tabletop is prepared in a similar way.

If you plan to install a sink, you need to leave space for it, which is covered with another formwork, fixed with spacers. The concrete mixture is poured, hardens for three days, then a countertop is installed from any material you like.

The second tier represents the combustion chamber and the walls that cover the stove. Such partitions are laid out in half a brick. Particular attention should be paid to the arrangement of the firebox.Its peculiarity is a two-row design, made of refractory brick inside and ordinary brick outside. The masonry is done in the traditional way.

The recommended firebox parameters are:

- height - seven rows for an arched opening or nine for a rectangular one;

- depth - approximately 60 cm;

- width - about 70 cm.

When the firebox is ready, you need to lay an additional two rows of masonry on top and install a smoke exhaust pipe. To obtain a chimney of the required diameter, you should alternately reduce the length of the laid out walls. Side ones - a quarter of the width of the brick. In this way, about seven rows are laid out. The chimney should be constructed in the shape of a rectangle, and its recommended height is from twelve to fourteen rows.

Which brick to use

In the case of building such a furnace, it is worth stocking up on three types of bricks: regular, refractory and facing. The latter is used optionally, if you need to give an aesthetic appearance to the stove or hide the ugly brick from which it was built. Building materials marked M-250, M-200 are excellent. In extreme cases, you can use the M-150. If we talk about sizes, they may differ: 250*120*65 mm, 250*120*80 mm, 288*138*138 mm.

Important! It is prohibited to use silicate clinker due to its properties. You should also not use hollow ones or those with holes.

A barbecue oven in a summer cottage, built with your own hands, is not only a device for preparing delicious dishes. It will become the highlight of the recreation area, and sometimes part of a real open-air kitchen.