Barbecue from a gas cylinder

If you have an empty gas cylinder left, you can use it to build a barbecue. It can be without a lid or closed. The second type of fryer combines several functions, including grilling. The closed design allows you to bake or smoke dishes, while the open design allows you to fry food. You can make a barbecue with your own hands, having carefully studied the process.

The content of the article

Why you should use a gas cylinder for a barbecue: the pros and cons of such a solution

The gas cylinder is a durable and simple design. It allows you to build grill pretty quickly. It is the cylinder that most often becomes the basis for a barbecue.

The advantages of its use include:

- good quality material;

- requires a minimum of financial investments;

- capacity - you can cook several products at a time, which is especially important when large groups gather;

- multifunctionality - the design allows you to fry, bake, smoke, adding variety to the preparation of dishes;

- The barbecue turns out to be reliable and durable.

But there are some disadvantages. Among them:

- large amount of work;

- the product turns out to be large and bulky - moving it will be difficult;

- requires a lot of coal;

- after several uses, the appearance suffers and becomes not very attractive;

- Food may not cook evenly.

Before starting work, it is necessary to select the right materials, including the container itself.

Which cylinder to choose

Products are classified into several types:

- Propane. They are cylindrical in shape and come in a variety of sizes. Volume varies from 27 to 65 liters. Most often, cylinders with a capacity of 50 liters are used.

- Oxygen. Their body is painted blue. More often they take containers with a volume of 40 liters. The walls are about 5–7 mm thick, which has a positive effect on the preparation of food. The design is perfect as an open barbecue grill. If you add a lid, then due to the shallow depth the product is only suitable for steaks. Larger pieces of meat will not fit.

- Automotive. A special feature is the absence of welds.

- From under freon. It has a wall thickness of about 1.5–2 mm. For a barbecue this is quite small.

To construct barbecue grills, it is recommended to use containers made of alloy or carbon steel.

Even in an empty cylinder there are gas residues, which are important to carefully remove first, because it is enough to start working with an angle grinder and the first spark will lead to an explosion. It is not recommended to perform any actions with the cylinder near an open flame.

Stages of making a barbecue from a cylinder

Creating a Dutch oven involves several steps. It is recommended that you familiarize yourself with the process to get the job done correctly.

Preparation

It was noted that some gas may remain in the product. Using such material is dangerous, so they start by removing the residue. It is enough to fill the container with water, which will allow the gas to escape.

Cylinder markings

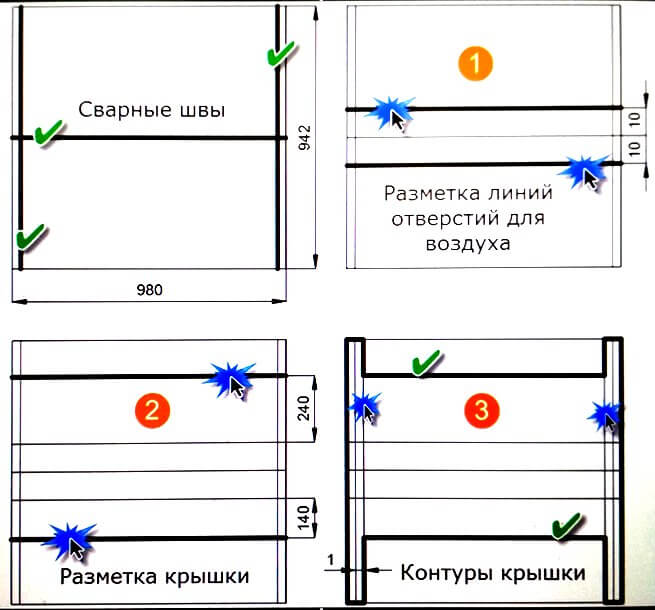

When the dangerous substance has been removed, markings begin. To do this, use a waterproof thick marker. It is necessary to measure the circumference of the product and subtract 1–1.5 cm from the obtained data per welding seam.

The remaining length is divided into 4 parts. On both sides of this line additional ones are applied at a distance of ¼ of the circumference. It is recommended to label each section to avoid confusion when welding the hinges.

From the back line they retreat half the distance to the middle line. This will be the border of the lid. Then they begin to mark the holes for the skewers. It is enough to step back a certain distance from the edge, and divide the length by the number of skewers. A grinder is used for cutting.

Making the lid and holes for the skewers

A long incision is made along the posterior line. Then 2-3 loops are created in this area and welded. This must be done before making any other cuts on the body to ensure proper placement of the cover later. When the hinges are welded, you can start working on the lid.

The cuts are made slowly and carefully; there is no need to rush. When the process is completed, the lid is lifted and checked to see how well it fits in place.

When creating holes for skewers, they begin to work with a small-diameter drill, setting the direction. Then use a tool with a larger diameter. It is recommended to start from the back. After this, they begin to drill holes in the front of the structure. They should be in the shape of the letter P. When all the holes are ready, they are finalized using a file of a suitable cross-section.

Creating a boost for oxygen circulation

To organize the air supply, several holes are made on the sides of the structure.It is important that they are not large in diameter, otherwise the coals will begin to fall out when using the grill. Therefore, it is better if there are more holes, but they will turn out to be small. To perform them, a grinder is used. The holes should be on the side parts of the structure. The bottom holes won't do any good.

Making legs

For the legs, any available materials are used. Profile requirements with a section size of 20 by 40 mm are better suited. The height of the legs and the angle between them must be selected taking into account the dimensions and features of the resulting barbecue. It is convenient to use a corner and a level when placing them to ensure that they are as even as possible. The parts are secured by welding. To ensure stability of the structure, it is recommended to use clamps when fixing the legs.

Finishing

When all the parts and holes are completed, start painting the barbecue. Heat-resistant paint must be used. It is recommended to first wrap the handle on the lid with electrical tape. The color is chosen based on your own preferences.

The result is a barbecue that will decorate your yard. You can cook dishes on it in various ways. The main thing is not to forget to take care of the structure so that it does not soon become unusable.