Soundproofing interfloor ceilings using wooden beams in a house: how to do it

Sound insulation of wooden floors is carried out using different materials that protect both from noise and from cold. This can be mineral wool, fiberglass, polyethylene foam and others. The pros and cons of materials, as well as installation technology, are described in detail in the presented article.

The content of the article

Material selection

Sound insulation of interfloor floors on wooden beams is carried out with various materials of natural or artificial origin. As a rule, these are loose raw materials in rolls or blocks that do not create a strong load on the floor. The main types of materials are:

- Glass wool – durable, elastic, vibration-resistant. Absorbs sound quite well and provides thermal insulation. It does not absorb water, but it is advisable to use a vapor barrier - this will extend its service life.

- Mineral wool – a natural material of low density, often used for interfloor sound insulation on wooden beams. Absorbs sounds well, protects from cold, but absorbs water. Therefore, installation is carried out with mandatory vapor barrier.

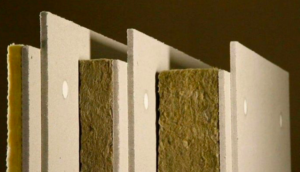

- Multilayer panels – modern materials based on sandwich panels and plasterboard sheets. They absorb sounds perfectly, although they are quite expensive and have a noticeable weight that puts pressure on the structure.

- Soundproofing of wooden floors between floors is also done using pressed cork. This is one of the most budget-friendly and at the same time effective options. The panels are rot-resistant, light in weight, and last 30-40 years.

- Foamed polyethylene absorbs noise and vibration well and has minimal density. However, it can shrink over time, is destroyed by exposure to the sun, and is a fire hazard.

- Bitumen and cork backing – kraft paper, produced in rolls, so it is very convenient to install. Thanks to it, sound insulation is provided between floors in a wooden house, while the load on the floor is small.

- Fiberglass It dampens structural noise well, i.e. sounds that travel through the frame. It is placed on a wooden floor, interfloor ceilings. The material is not resistant to constant pressure, so areas of hard contact should be isolated using a gasket.

How to lay the material

Soundproofing of interfloor floors using wooden beams is usually carried out directly during construction work or at the rough finishing stage. The step-by-step description of the instructions looks like this:

- First, the logs are treated with an antiseptic to prevent the formation of mold and other fungi.

- A rough flooring is mounted on the underside of the beams, for example, from wooden boards of small thickness 20-30 mm.

- In order for sound insulation in a house with wooden floors to be effective, it is necessary to overlap the vapor barrier by at least 10 cm, and secure the joints with construction tape.

- Soundproofing material is placed on the vapor barrier, which often also acts as insulation. For example, it could be a roll of mineral wool or polyethylene foam.

- When the floor between floors in a wooden house has been soundproofed, the material must again be covered with a vapor barrier membrane in the same way as the previous layer.

- Then a subfloor is installed, for example, from two layers of chipboard. The first is placed directly on the joists, and the second is laid so as to cover the joints of the previous one (in a checkerboard pattern).

Additional noise protection can be provided using different materials. Moreover, in order for the work to be done efficiently and the structure to withstand the load, you need to make a reliable subfloor and finishing. If, for example, a floating floor is installed, it will not be in direct contact with the beams, which will provide additional protection against vibration.