Insulation for a wooden entrance door in a private house: how and how to insulate it

The insulation for the front door must be resistant not only to temperature changes, but also to high humidity. For these purposes, polystyrene or foam rubber is often used. Before starting work, it is worth considering the insulation of the gaps between the leaf and the door frame. How to do this and what material to choose is described in the presented material.

The content of the article

Types of insulation

Insulation of the front door is carried out in cases where the structure has begun to dry out due to natural wear and tear, for example, due to humidity or temperature changes. This can be determined by sensations (strong wind blowing from the street), as well as by external signs:

- Gaps form between the door frame and the surface of the opening wall. The voids must initially be foamed - this is the main means of insulating doors in this case. But the layer begins to collapse, especially from the outside. Therefore, there is a need to install new material.

- Gaps form between the sash and the frame - mainly due to poor-quality wood of the door itself or errors during installation work.

- It is also necessary to figure out how to insulate a door in cases where the insulation material itself wears out. It may suffer due to dampness; for example, mineral wool shrinks greatly in these cases.

There are 2 ways to insulate the front door - you need to do it from the outside and from the inside. And first you need to choose the material itself. Examples include:

- Mineral wool is inexpensive, retains heat well and does not allow sound to pass through. But it quickly deteriorates in the presence of high humidity, so it is not suitable, for example, for a door to a bathhouse.

- Polystyrene foam also protects well from the cold and dampens sounds, but it begins to crumble, especially when laid outside.

- Door insulation is often done with polystyrene foam. Unlike polystyrene foam, it does not crumble because its strength is 8 times greater. Resistant to moisture and temperature changes.

- Foam rubber is also suitable for insulating a wooden entrance door, because it is not afraid of moisture and freezing temperatures. However, if it is too dry outside or indoors, it may begin to crumble.

- Polyurethane foam has high wear resistance and is well fixed on the surface. But this door insulation can only be installed if you have the equipment - you will have to call a team.

The materials for insulating the door itself are described above. You can also use box seals, among which the following types of products are distinguished:

- The foam strip is inexpensive, easy to install with glue, but wears out in one season.

- The silicone strip is resistant to moisture, but as it wears, it splits into several pieces.

- Insulation of doors in a private house is also done using a rubber seal. It is more reliable because it is resistant to moisture and wear.

- Polyurethane insulation is no less durable. Such strips have a sticky base, due to which they reliably adhere to the surface.

- The best in terms of durability can be considered thermoplastic.

How to insulate a door: step-by-step instructions

Once the insulation for the wooden entrance door has been selected, you can proceed directly to installation. The work is being carried out in several stages, and most likely it will be necessary not only to replace the old material, but also to repair the door frame and openings.

Preparatory work

Before insulating the front door, it is recommended to carry out the following preparations:

- Reinforce the hinges with new long self-tapping screws.

- If you use dense material, add another loop.

- Repair the distortion of the frame and the door leaf itself.

- If necessary, change the lock, handle and other types of door hardware.

Seal installation

Now you need to understand how to insulate the front door in the openings, i.e. what strip to fix on the box so that there are no gaps. Most often, polyurethane or thermoplastic is chosen for this. The work is carried out in several stages:

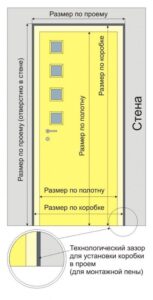

- Take several measurements of the gaps between the frame and the door.

- Cut the tape to the appropriate thickness.

- Glue it into the groove along the perimeter.

- If the material does not have an adhesive base, it is secured with staples using a construction stapler.

- If the box is worn out and the gaps have different thicknesses, it is necessary to widen and deepen the groove, and go along the edge with a grinder.

- Check how the material is laid - the door should close freely, but at the same time there should be no gaps.

Insulation of the canvas

Next you need to insulate the door - the main steps are as follows:

- The fabric is removed from the loop.

- Dismantle the old insulation.

- Measurements are taken and the dimensions of the insulation are determined.

- Cut out a part from foam rubber or other material that is slightly larger compared to the dimensions of the canvas - about 10 cm on each side.

- Fix it around the perimeter of the door with a stapler.

- All excess parts are cut off.

- The top is covered with artificial leather. If foam rubber was used, rollers are formed from the edges.

- A pattern is formed on the surface of the canvas by nailing at a certain interval.

You can perform insulation using polystyrene. In this case, MDF is chosen for the final cladding. The canvas increases in weight, so you will need to install a third loop.

Thus, you can carry out insulation yourself, but only after taking accurate measurements. If the door is too dilapidated, it is better to completely replace it along with the opening. If it cannot be dismantled, you can temporarily glue a seal between the box and the canvas, and carry out major repairs in the summer.