Warm electric floor in the bathroom: how to do it, do you need waterproofing?

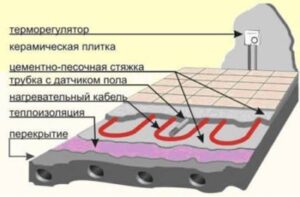

A warm floor in a bathtub is made using a heating circuit, to which a sensor and thermostat are connected to control the temperature. The work can be completed literally in one day, but after that you need to wait at least a month for the screed to fully mature, after which you can start using the system. The article provides instructions on how to make an electric heated floor in a bathroom, as well as recommendations for preparing the necessary materials and arranging waterproofing.

The content of the article

What do you need for work?

First of all, you need to prepare materials and tools for work:

- the base of the floor is a heating cable, which can be single- or double-core;

- temperature sensor;

- pipes for the floor - usually plastic ones are chosen because they are convenient to work with (length up to 1.5 m);

- mounting tape;

- temperature sensor;

- thermal insulation;

- waterproofing;

- perforator;

- hammer;

- chisel.

A separate important topic is waterproofing and heated floors in the bathroom. Covering with film is mandatory, because water greatly destroys concrete over time. Even if the apartment is located on the ground floor, and there is no risk of flooding the neighbors, protection from moisture will still be needed.

Most often, modern materials are used for this:

- thick polyethylene film;

- fiberglass;

- roofing felt;

- PVC film;

- cement-polymer mixture;

- mastic (water base).

Thus, there is no need to doubt whether waterproofing is needed under a warm floor.Despite the fact that the contour area is very small, the impact of moisture is felt more and more over time. The liquid penetrates into the cracks, directly into the screed and destroys it from the inside. If you do not provide for laying the film, within a few years the floor will begin to deform.

Step-by-step installation instructions

Installation work is carried out in several stages:

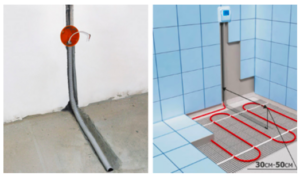

- A thermostat is installed to control the temperature and automatically maintain it within a certain range. It is mounted in a pre-made recess in the wall surface at a height of no more than 1 m.

- From this recess, 2 grooves are made vertically and the sensor wires are laid in one of them, and the power wire in the other.

- The base of the floor is cleaned of dust and a self-leveling mixture is laid (a cement screed can be used instead). When the floor is leveled, it is treated with a primer.

- Waterproofing is placed on the prepared surface. If the material is in a roll, it is straightened and heated with a hairdryer. Glue it onto the subfloor and process the seams. If it is, for example, liquid mastic, it is applied with a brush or spray. And it’s better to do 2 layers.

- Next, thermal insulation is laid. This step is optional, but desirable, because in the absence of insulation, quite a lot of energy is lost. This is especially true if the apartment is located on the ground floor. The material usually used is cork, foil polyethylene foam or penoplex.

- Lay the heating cable, moving from the junction of the power wire with the thermostat. A steel mounting tape is fixed to the thermal insulation material at intervals of 40-50 cm. The cable itself is placed in a zigzag and secured to the floor using a mounting tape.

- During cable installation, a minimum of 6 cm is left between its turns, and the distance to the wall is 10 cm. Several turns are made with a minimum radius equal to 5 diameters of this cable. Also maintain a gap of 20-25 cm from the pipe and the heating device.

- Now it’s time to install the temperature sensor - it is placed in the pipe itself and placed in the space between any 2 turns of the cable. A plug is placed on one side of this pipe to prevent the ingress of cement mortar. The sensor leads are fixed to both contacts of the thermostat. After this, you can seal the vertical grooves using plaster.

- Then you need to turn on the devices for a while to check its functionality. If everything is in order, you can pour a screed, the thickness of which can be from 3 to 10 cm. It is optimal to purchase a special mixture for a warm water floor.

The installation process itself is not very complicated, but it takes quite a lot of time in the sense that the finishing is done only 3-4 days after pouring the mixture. Next, you will have to wait another 4 weeks for the screed to fully mature. Only after this can you turn on the heated floor and start using it.