Thermal insulation of the floor in an apartment: how to make insulation, options

Insulation of floors in an apartment is mainly relevant for rooms on the ground floor. If there is extreme cold coming from the concrete, it is recommended to use penoplex, mineral wool or their varieties. How to choose the right material and how to lay it correctly is described in the presented article.

The content of the article

Choice of insulation

Thermal insulation of the floor in an apartment is carried out using different materials, for example, loose materials, different types of cotton wool, and also based on foam plastic. The most common types are:

- Mineral wool – relatively inexpensive, durable, protects well not only from cold, but also from sounds. But it crumbles due to prolonged exposure to moist air, so waterproofing should be used during installation.

- Penoplex – universal insulation for different rooms. Lasts a long time, is not susceptible to moisture and rotting. Particularly suitable for apartments located above cold basements (ground floor).

- Polyurethane foam - another effective insulation. It is applied by spraying, which eliminates seams and joints. Resistant to moisture, rodents, and not susceptible to rotting. Such insulated floors in the apartment will last a very long time. However, installation requires special equipment and protective clothing.

- Expanded clay – bulk insulation, affordable. It is used directly when forming the screed.Quite effective, but takes up a lot of space, so it’s not suitable for low rooms.

- Gypsum fiber durable, has a safe composition, and is easy to install. It has a smooth surface and small thickness. At the same time, it costs more than some insulation materials.

- Fiberboard does not protect against the cold so well, but is quite suitable for apartments not located on the ground floor. The panels are cheap and easy to use.

How to insulate a wooden floor

Options for floor insulation in an apartment can be different, they depend on the characteristics of the surface. For example, if the base is wooden logs, then the material is placed between them. They work like this:

- The old covering is removed, which will require opening up the floor. They clean it from dust, lay the waterproofing overlapping by 15 cm. This can be a plastic film, the joints of which are taped. The edges extend 5 cm onto the wall.

- Take measurements, if necessary, cut sheets of insulation and place them in the interval between the joists. The joints should be as tight as possible, without gaps.

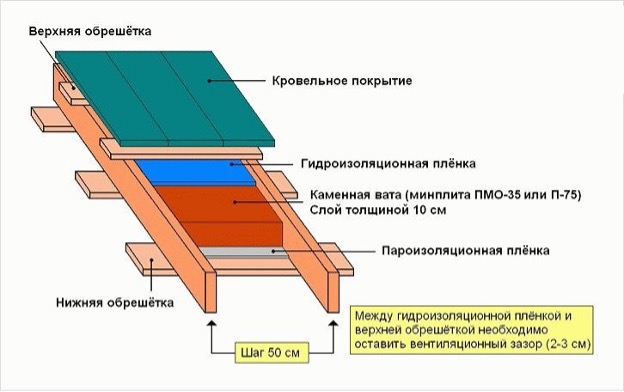

- If wool (stone, mineral) is used as the material, a vapor barrier must also be installed. It is also mounted with an overlap, the joints are fixed with tape.

- Next, it remains to lay wooden boards or thick plywood, OSB.

- At the last stage, the finishing coating is installed, for example, linoleum, laminate.

How to insulate a concrete floor

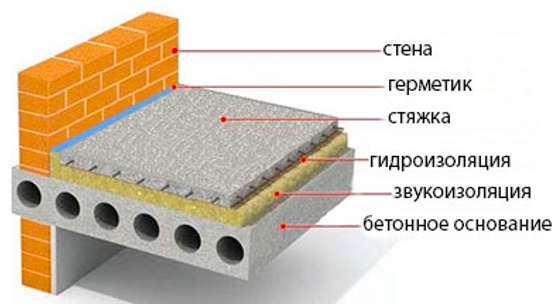

The insulation technology in this case differs from that described above, the main stages are as follows:

- If the screed is old and there are signs of severe wear, it is advisable to dismantle it.

- Cleaning of dust and debris.

- Lay waterproofing.

- Then comes the turn of insulation, for example, polystyrene foam or mineral wool.

- It is covered with a vapor barrier.

- Next, install a metal mesh with fairly large cells from 5 to 10 cm.

- Prepare the solution and pour a new cement screed.

- Level the surface and let it dry for 2-3 weeks.

- Only after this can the finishing coat be applied.

Thus, the insulation methods are somewhat different from each other, but the sequence of laying the layers is similar. In the case of a concrete floor, you can either pour a screed or place wooden logs on the finished surface. To ensure durability, it is important to use hydro- and vapor barriers.