Soundproofing a toilet, bathtub and water pipes in an apartment: how to do it yourself

Soundproofing a toilet in an apartment is achieved in 2 main ways - using materials that dampen sounds well, and also by installing a duct. The second method may seem simpler; moreover, a well-made fence allows you to hide pipes and other communications that spoil the appearance. A detailed description of both noise protection technologies is presented in this article.

The content of the article

Use of sound-absorbing materials

High-quality insulation of a toilet in an apartment is planned already at the installation stage, when the pipe material and fasteners are selected. An overview of the main materials, their pros and cons is presented in the following sections.

Foam rubber

One of the modern types of materials that ensure sound insulation of a bathroom is foam rubber. It is characterized by high density (65 kg/m3) and at the same time elasticity, which ensures strength and durability. Rubber is produced in sheets and rolls.

The thickness starts from 8 mm, and even this is enough for the noise insulation in the toilet to amount to 26 dB (absorption of sounds comparable in strength to the whisper of a person at a distance of a meter). However, there is also a disadvantage associated with high cost.

Rigid polyurethane foam

This is a continuous shell around a sewer pipe, which consists of 2 “shells” connected end-to-end. They are quite strong and reliable, resistant to rotting. Density is 60 kg/m3. Polyurethane foam is quite affordable, although the sound insulation of the toilet is lower than in the case of rubber and corresponds to approximately 20 dB.

You should also keep in mind that the wall thickness is 40-50 mm, which is not always convenient in narrow rooms. Another disadvantage is that the joints and ties need to be additionally glued with clamps. But there are also advantages - the material is more affordable.

Foamed polyethylene

Another way to soundproof a toilet is to use polyethylene foam. This is an elastic, fairly light material with a density of only 35 kg/m3. It has good noise-absorbing properties. Even with a small wall thickness of 2 mm, it dampens sounds with an intensity of 32 dB, which corresponds to a quiet conversation or the ticking of a wall clock.

Another important advantage is the low price and ease of installation. The material is produced in the form of hollow tubes, which are mounted directly on top of the riser. It is also produced in the form of rolls, which are convenient to transport in any quantities. Some types of rolls already have an adhesive layer, which makes the instructions on how to soundproof a toilet much easier.

Regardless of the choice of a particular material, it is important to purchase a special fastening element. It is best to use shock-absorbing pads made of dense rubber, which are installed in the space between the clamp and the pipe. Places where pipes pass through a wall or ceiling should be insulated with rolled material or intumescent sealant.This ensures high sound insulation of water pipes.

Box installation

Soundproofing of the bathroom is also achieved by installing a box, which not only suppresses noise, but also provides an aesthetic appearance. The box can be purchased ready-made and assembled according to the instructions. The market offers mainly plastic models with average sound insulation. They are affordable, but will likely require additional sound protection, such as sealant or stone wool.

On the other hand, soundproofing a toilet bowl can be done with your own hands - the box is assembled independently from plasterboard sheets. This is a more reliable design that dampens sounds better. To work you will need:

- actual plasterboard sheets with moisture-resistant properties;

- metal profiles with a cross-section size of 40*40 mm;

- self-tapping screws of 2 types - for working with metal and drywall;

- construction level;

- roulette;

- hammer drill for drilling concrete;

- screwdriver;

- assembly knife;

- Bulgarian.

Soundproofing water pipes in an apartment is done with your own hands, the main steps are as follows:

- Taking measurements and creating a drawing. It is necessary to mark the attachment points for guides with U-shaped profiles, stiffening ribs, the location of partitions and a frame with an access door.

- Clean the old surface from dirt.

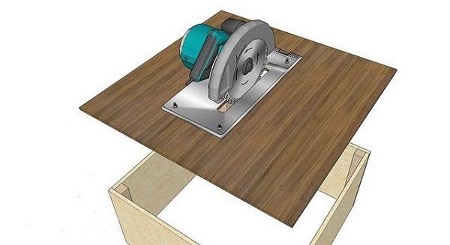

- They measure the profile, make marks and cut it into fragments with a grinder.

- They assemble the frame, fastening the profile with self-tapping screws, and use a screwdriver.

- Do-it-yourself soundproofing in the toilet is done with plasterboard sheets, which are also marked and cut. In this case, you need to ensure that there are as few chopped fragments as possible, and as many whole ones as possible. The edges are sanded.

- The sheets are secured using special drywall screws. This is how soundproofing of a bathroom in an apartment is ensured.

- Next, an access door and ventilation holes are made.

- The last stage is decorative finishing. You can cover the sheets with tiles or simply paint them. The surfaces are pre-treated with a primer.

Thus, sound insulation in the bathroom and toilet is achieved even at the stage of installation or replacement of the pipeline. It is important to use high-quality materials and connecting elements that provide good noise protection. You can also install a box, and to ensure maximum insulation, use both options. If the noise is noticeable, the walls in the toilet are additionally soundproofed. For this, modern materials are used, for example, stone wool, gypsum, balsa wood or penoplex.