Soundproofing an apartment in a panel house: how to do it yourself

Sound insulation in a panel house can be done with or without the installation of a frame. The first method is more effective; it is used to decorate walls shared with neighbors. The article discusses the features of each technology, types of materials, as well as step-by-step instructions for installing acoustic panels.

The content of the article

Types of noise and types of sound insulation

Sound insulation in a panel house is required more often than, for example, in a brick house. This is due to the small thickness of the walls, which allow sounds from the street, but especially from neighbors, to pass through. This is due to the characteristics and types of noise that spread throughout the panel house:

- Air – spreads directly through the air, i.e. not in a solid, but in a gaseous wall. These are any household noises, from conversation to music to barking dogs.

- Shock – vibration noise that spreads along the walls, floor, ceiling from neighbors. For example, if the music itself comes through the air, then the rhythmic beat and bass come through the material of the walls.

- Structural – one of the types of impact noise, differs from it in its greater range. For example, on the first floors of high-rise buildings, vibration from the metro or from very loud music from neighbors may be felt. In this case, the sound wave travels throughout the entire structure of the house.

When considering how to make sound insulation in an apartment of a panel house, it is recommended to consider several technology options:

- Frameless - The easiest way. In this case, slabs of the required size or membranes are attached to the surface of the walls, floor, or ceiling.

- Frame method – first, guides are installed from a metal profile or wooden slats, after which the sound insulation of the walls in the panel house itself is installed. This is a more efficient technology because the frame provides durability and the ability to lay an almost unlimited number of layers of material.

- Floating – such soundproofing of a panel apartment is only suitable for the floor. The material is spread on the surface, covered with waterproofing, and then a reinforcing screed is installed. After this, a finishing coating is applied, for example, linoleum or PVC tiles.

Thus, sound insulation of walls in a panel house can be implemented using different technologies. Moreover, if you are planning a major overhaul, you can use all 3 methods. Thus, the interior walls of your own apartment are finished with ordinary membranes without constructing a frame.

But it is better to install it to insulate the walls and ceiling that lead to the neighbors. In order to protect yourself as much as possible from noise and not cause inconvenience to the residents below, you should also install a floating floor. This is the most reliable way to make sound insulation in a panel house.

What materials are used

All materials that absorb noise, depending on their density and texture, can be divided into 2 categories - soft and hard. As a rule, for effective noise protection, both types are used, including in combination with each other (structure of 2-3 layers).

Soft materials

Soundproofing an apartment in a panel house is often done using soft materials:

- Membranes – fragments of bitumen or rubber with a polymer coating. They usually have an adhesive backing and are already cut into squares or rectangles, so installation takes literally a few minutes. Typically used for interior walls.

- Needle-punched fabric – more effective soundproofing of an apartment in a panel house, recommended for finishing walls, ceilings and floors leading to neighbors. The material is quite dense and does not contain hazardous substances. It can also be used for insulating pipes (finishing a decorative box).

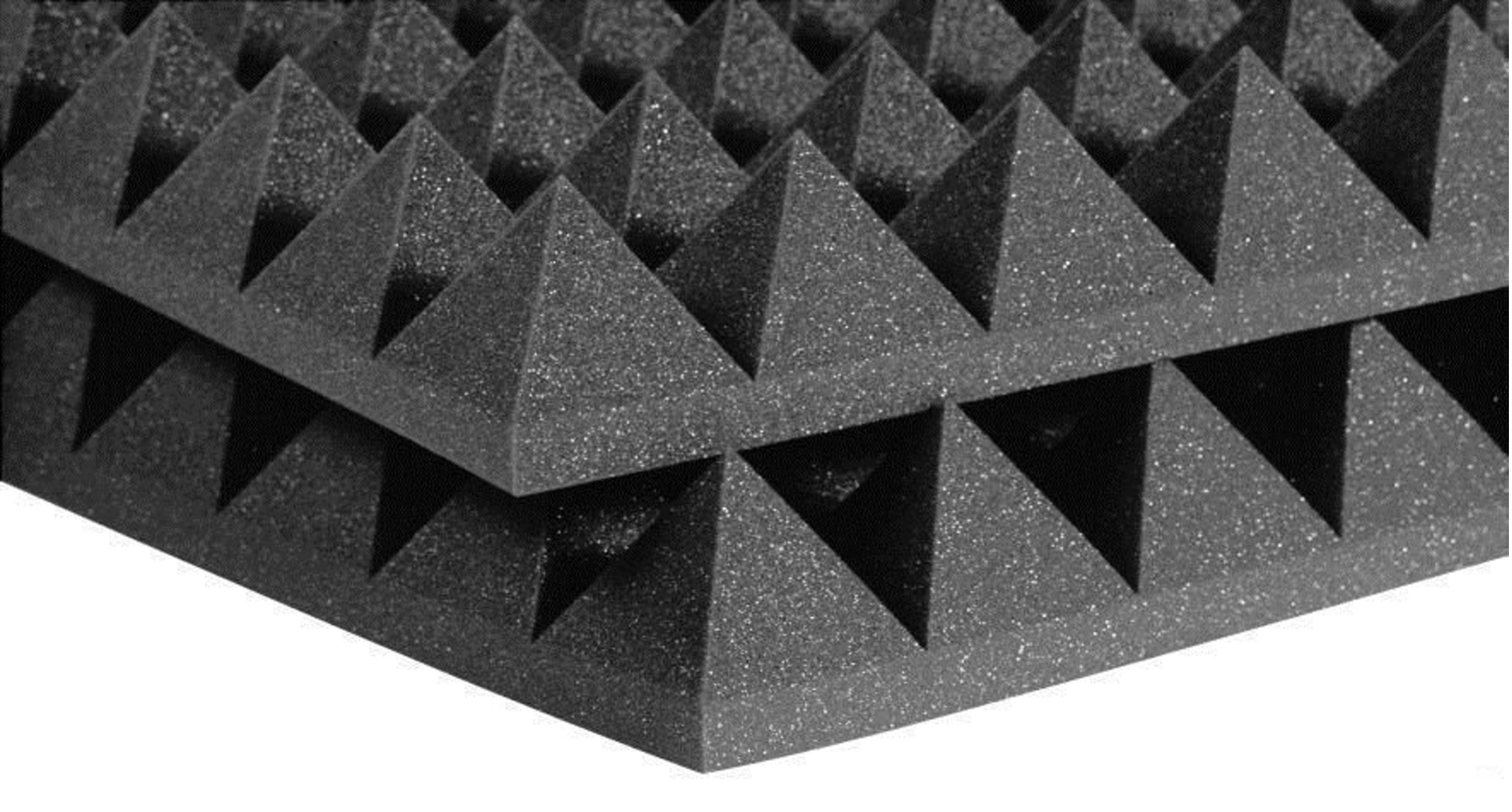

- Acoustic foam rubber - a lightweight and very comfortable insulator that dampens the sounds of music and even vibration well.

Hard materials

Soundproofing of a panel apartment is also done on the basis of solid materials:

- Basalt slabs – protect not only from noise, but also from cold. They do not collapse under the influence of moisture, are durable and are relatively inexpensive.

- Minvata – a traditional heat and sound insulator, has a natural composition. It dampens noise well and is easy to install. But you need to keep in mind that it absorbs moisture, so mandatory waterproofing is required.

- Combined type panels – consist of several layers based on cellulose, sand and coniferous wood residues. Very convenient for frameless soundproofing. They are used correctly in a suspended ceiling system, as well as for finishing walls between rooms.

Step-by-step instruction

Do-it-yourself soundproofing in a panel house is carried out in several stages. If we take the simplest frameless method as a basis, the technology will be as follows:

- First you need to take measurements, calculate the number of panels, and make cuts if necessary. The surface is also prepared - wallpaper or slabs are removed from it and completely cleaned of dust. If there are strong unevenness (from 1 cm), smooth out with putty.

- An acoustic substrate is made, for example, from Wolf Vlies vibration-isolating canvas. It is sold in rolls that are simply unrolled and run from top to bottom like wallpaper. It must be mounted very tightly so that the joints have virtually no gaps.

- Dowel nails are used as fasteners.

- To properly soundproof an apartment in a panel house, acousticians recommend drilling holes directly through the panels. That is, first apply the material, and then substitute a hammer drill or drill with a 6 mm drill.

- Then a dowel-nail is driven into this hole using a regular hammer. All joints are carefully treated with sealant.

- After sealing the seams, you need to wait a few minutes. At this time, you can install adjacent panels. Where necessary, holes are pre-made, for example, for sockets.

- Upon completion of the work, the seams are additionally taped using construction tape.

- The result should be something like this.

At this point the main work can be considered completed. All that remains is to start finishing. But first you need to install slabs, for example, from plasterboard. Then the surface is primed, after which they begin painting or wallpapering.