Do-it-yourself woodchip cutter: how to make it, drawings and size of the machine

At home, you can design a wood chip cutter with your own hands. To do this, you will need to choose a gasoline or electric engine, make a stage and decide on the size of the frame. Step-by-step manufacturing instructions, as well as examples of drawings, can be found in the presented material.

The content of the article

Tools, equipment and drawings

First of all, you need to clarify the dimensions according to the drawings of the wood chip cutter with your own hands. You can take one of several options as a basis:

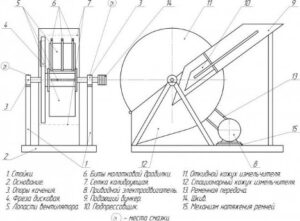

- Classic design.

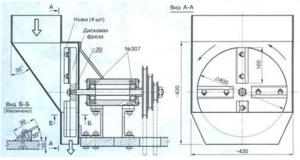

- Do-it-yourself wood concrete wood chip cutter (side and back views).

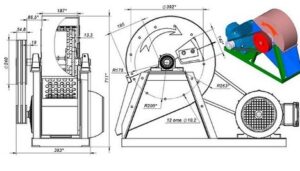

- Compact device.

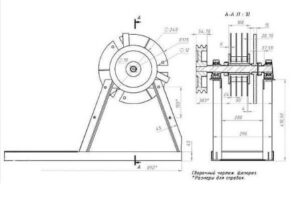

- Another option for wood chip cutting.

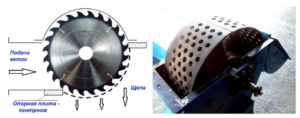

As you can see, the basis of the design is an asynchronous motor, a gear transmission mechanism and saw blades. It is for them that the dimensions of the body and frame are selected. Moreover, in order to construct a homemade wood chip cutter, you need to take care of the following equipment and tools:

- electric or gasoline engine power 2.5-3 kW;

- disks made of sheet steel (you can purchase ready-made ones or turn them on lathes or milling machines);

- shafts and pulleys with belts;

- gears;

- grinder and discs for working with metal;

- welding machine with electrodes;

- hammer;

- drill and set of drills;

- roulette;

- square;

- marker for marks;

- open-end or adjustable wrenches;

- thick gloves;

- helmet for welding.

Step-by-step instruction

To make a chip cutter with your own hands, select drawings, determine the dimensions and materials, and then proceed as follows:

- Cut off part of the channel and remove the excess length of the longitudinal part.

- Drill 4 holes in it, into each of which a bolt will be inserted.

- Insert 2 housing bearings and secure them with bolts.

- This workpiece is welded to steel. To do this, cut off part of the plate, form a hole and weld it perpendicularly.

- Take a fragment of a round pin (it should be thick enough). To make a do-it-yourself chip machine, a bolt is made from this pin. A steel washer is put on it and scalded.

- Take the shaft and fix it to the bearings (the washer is needed for additional support).

- Discs for working with wood are fixed onto the shaft (2 elements with the same diameter and spacing between the teeth). 2 washers are fixed between them.

- Another plate for the shaft is cut out and welded.

- To make a wood chip crusher with your own hands, as in the photo and drawings, you need to weld the third plate to the ribs of the first two. All surfaces after welding are carefully cleaned with a grinder.

- Next, the mechanism is welded to the object stage, which is made in advance, focusing on a convenient height.

When the do-it-yourself woodchip crusher is ready, it needs to be tested. It is important to understand that the quality of work directly depends on the engine power. For example, if it is within 3 kW, you can work with small fragments 5 cm long. And if you increase the power to 4 kW, it is quite possible to process wood waste 7-8 cm long.