Do-it-yourself Russian housekeeper stove made of brick or metal: drawings

The housekeeper differs from the classic Russian stove in its smaller size. Its width does not exceed 1 m with a standard height of 2-2.5 m. Thanks to this, such a structure can be installed in almost any room. Step-by-step instructions for assembling a housekeeper stove, drawings and masonry diagrams can be found in the presented material.

The content of the article

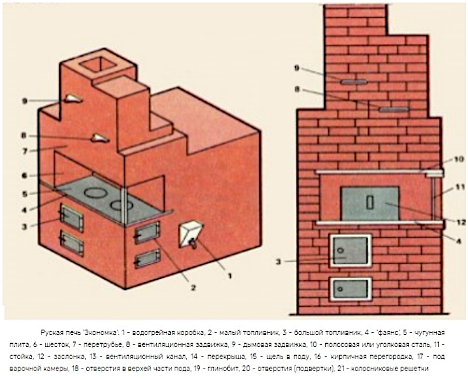

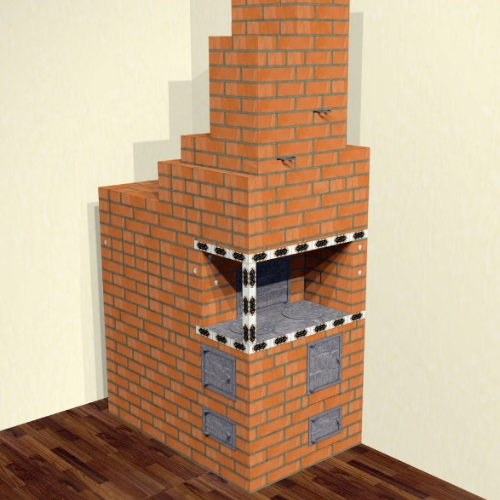

Furnace design and drawings

As a rule, you build a housekeeper stove with your own hands from brick. This is a small structure, with a height of 2-2.5 m, a width of no more than 1. It consists of several elements:

- Base with 2 combustion compartments. Each has its own container for falling ash, an ash pit and a grate.

- The first row is brickwork with 4 inspection grooves necessary for cleaning the firebox chimney.

- The base with the hob is located above the fireboxes.

- Auxiliary combustion chamber - for heating in the warm season, as well as for cooking.

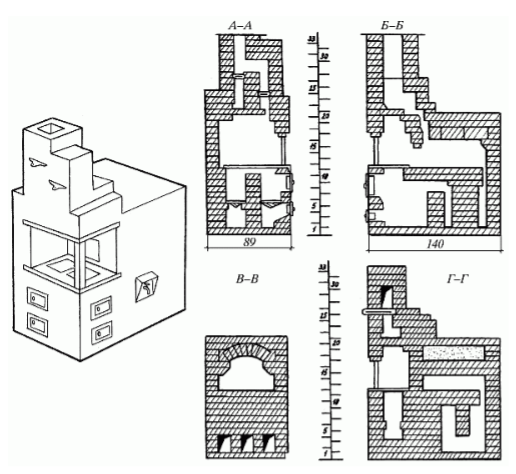

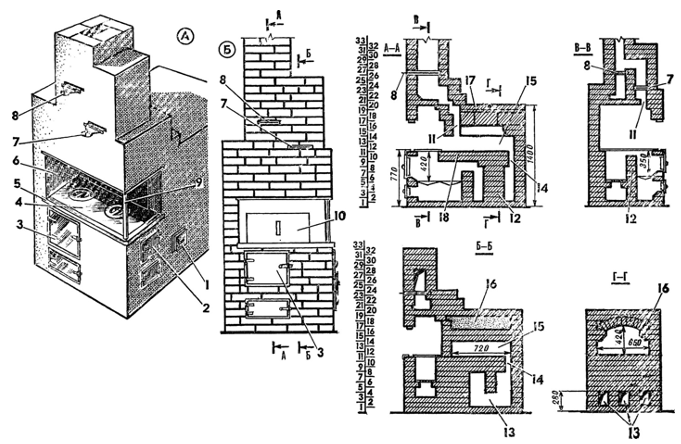

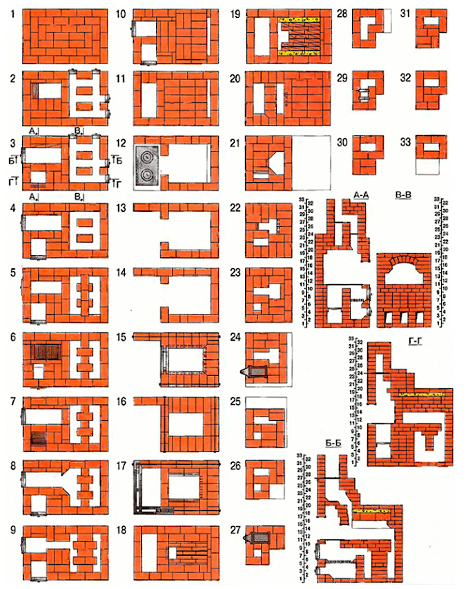

The order of the Russian housekeeper stove is shown in the diagram.

View from different sides.

You can also use this diagram (A – general view, B – front side).

What you need for work

The housekeeper stove is made from brick with your own hands and has the following dimensions:

- length 140 cm;

- width 89 cm;

- height 225 cm.

The following tools and materials are used for work:

- Master OK;

- construction tape;

- ceramic bricks – 1300 pcs.;

- kneading container;

- clay 2.5 tons;

- sand 2 tons;

- file;

- building level;

- steel corner;

- grate;

- door;

- chimney damper;

- hammer;

- pick.

Brick oven

Do-it-yourself wood-burning stove-stove is installed in stages, the main steps are shown in the diagram.

The procedure is as follows:

- Mix a solution of sand and clay, add a little water to get the consistency of thick sour cream. Lay out the first row according to the diagram.

- The second row is placed taking into account the arrangement of the ash pit channels, as well as the blower.

- An asbestos cord is placed on the frame of the blower door and a new row is placed on top of it.

- On the other side they put a door for a compartment with an air vent.

- Now we need to install the grate bars. To do this, pre-cut the edges of each brick on the inner row.

- When installing the grate, leave a minimum gap of 4-6 mm and place an asbestos cord there.

- Next, bricks are laid according to the pattern up to the 10th row. Here you need to install a hob.

- When laying the 11th row, a gap is also left and an asbestos cord is laid.

- Each brick is cut off, forming an acute angle. The roof of the cooking compartment is formed. Screeds are installed on the sides to secure the structure.

- Similarly, place the ties at the mouth of the stove.

- At the last stage, a transition “corridor” is formed, which goes between 2 fireboxes.

- All that remains is to make a chimney with an air damper. For installation, it is optimal to use a sandwich pipe.

Next, you need to dry the structure, leaving it for several days. You can speed up the process by adding no more than 2 kg of small firewood and burning it completely. It is recommended to repeat several such cycles once a day for 4-5 days. During the first fires there will be strong smoke. This is normal because the bricks lose a lot of water.Next, you need to carefully inspect the masonry, if necessary, eliminate the defect, after which you can start kindling.

Metal stove

You can also assemble a metal stove with your own hands. This is much faster, although this design is less durable and rather resembles a hiking option. For work you will need steel sheets with a thickness of 4 mm, as well as other materials and tools:

- steel corners;

- steel pipes (diameter 1.5-2 cm);

- instead of pipes, you can take fittings of approximately the same diameter (grid bars are made from it);

- arc welding with electrodes 3;

- grinder and cutting wheel;

- construction tape;

- marker for marks;

- hammer.

The algorithm is like this:

- They draw up a drawing, transfer the dimensions onto steel sheets, and make marks with a marker or pencil. Cut the sheets with a grinder, get 5 rectangular fragments.

- Weld the bottom to 2 side panels. During work, you need to use a square so that the sides are connected strictly perpendicularly. The second side is fixed in the same way.

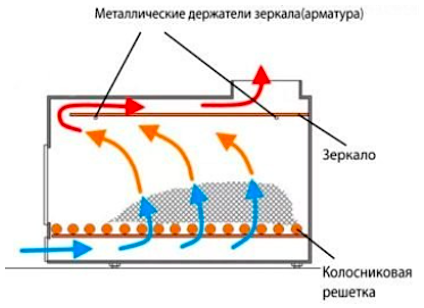

- Weld the back panel by inserting it between the sidewalls. Markings are made to determine the location of the ash pan, firebox and grate. The latter are installed at a height of 10-15 cm, for which the corners are welded in advance so that the shelf “looks” down.

- Now you need to make grate bars from fittings or pipe scraps. They are welded together so that the interval between adjacent strips is 4-5 cm.

- The grille is not welded to the corners, since it should be easily removed at any time for cleaning.

- Weld 2 pieces of reinforcement to place the reflector at the top of the stove. This element is required to separate the space of the firebox and the chimney; it can also be removed.The length of the reflector should correspond to 10/11 of the length of the entire structure - the “extra” part is needed in order to leave a gap through which smoke will escape.

- Next, measure the diameter of the chimney and cut a corresponding hole in the surface of the cover. After that, it is welded to the stove. Form 2 jumpers - wide and narrow. The first is mounted in the upper part, the second - at the same level with the grate to separate the doors of the ash pan and the combustion chamber.

- The firebox door is formed - practically it should correspond to the width of the stove. The ash pan door can be made narrower.

- Handles for doors are made, for example, from scraps or fittings. Install the latches.

- Supports are also made from sections of metal pipes. Nuts are welded to their ends and a bolt is screwed in.

- All that remains is to make a chimney from a pipe with a diameter of 15 to 20 cm. It is led through in advance done a hole in the thickness of the wall, forming 45 angles along the wayO.

Next, you need to carefully inspect the structure and perform a test fire. The chamber must be completely sealed - make sure that the smoke goes only into the chimney. If necessary, you can weld patches from scrap sheets of the same metal.