The floor in the steam room of a frame bath on stilts: how to make a heated floor with your own hands

When building a floor in a frame bathhouse on stilts, it is important to consider several key aspects. First of all, this concerns reliability, structural stability and effective waterproofing. A frame bathhouse on stilts assumes the presence of an air gap between the ground and the floor, which provides additional protection from moisture and cold. However, this also requires a more careful approach to floor insulation to ensure comfortable use of the bath all year round.

The content of the article

Installing a floor in a frame bath: stages of implementation

This is a complex and multi-step process that requires careful planning and adherence to technology. At the first stage, the foundation is prepared. First you need to make sure that the pile foundation is reliable and stable. The piles must be installed strictly vertically and at the same level to prevent future deformation of the floor. After this, the logs are installed, which are the basis for the floorboards.

At the second stage, you should pay attention to waterproofing. A waterproofing layer is necessary to protect wooden elements from moisture, which is inevitable in a bathhouse.This can be a roll of waterproofing laid over the entire surface of the floor, or a liquid membrane applied with a roller or brush. Waterproofing should be applied evenly, without gaps or folds.

The third stage is the installation of floorboards. Their choice should be based on moisture resistance and ability to withstand high temperatures. Boards made of larch or heat-treated wood are best suited. During installation, it is important to provide a small gap between the boards to compensate for their thermal expansion and provide ventilation.

Important aspects of installing a floor in a frame bath:

- Checking the level and stability of the pile foundation.

- Installation of logs on the foundation.

- Applying a waterproofing layer.

- Selection of moisture-resistant materials for floorboards.

- Providing ventilation under the floor.

Mandatory actions before starting work

Before starting work on installing a floor in a frame bath, it is necessary to perform a number of mandatory actions to ensure the quality and durability of the structure. The first and most important thing is a thorough inspection and preparation of the construction site. It is necessary to make sure that there are no obstacles at the site of future construction, such as large stones or tree roots, which could interfere with the installation of piles and joists. It is also important to check the groundwater level and, if necessary, provide drainage systems to prevent flooding.

The second mandatory action is the development of a detailed construction plan. It is necessary to clearly determine the dimensions of the bathhouse, the location and dimensions of the steam room, the installation locations of piles and logs. You should also consider the location of ventilation holes and pipes if a heating system is provided.The plan should include all design details, including floor-to-ceiling heights, door and window locations, to avoid mistakes during the construction process.

The third necessary action is preparing all the necessary materials and tools. This includes timber joists, floorboards, waterproofing materials, and tools such as a hammer, saw, level, tape measure and marking pencil. Preparing all the necessary materials and tools in advance will avoid delays and errors during the work process.

How to make a warm floor in a frame bath with your own hands

Creating a heated floor in a frame bathhouse with your own hands is a completely doable task. To do this you will need to follow a number of steps:

- laying waterproofing and insulating layers;

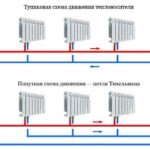

- installation of a heated floor system, which can be either electric or water;

- connecting the system to a power source or boiler in the case of a water heated floor;

- installation of a subfloor on top of a heated floor system;

- finishing of the floor, which can be made of wood or tiles depending on the functional purpose of the room in the bathhouse.

Base Layers

The “pie” of the floor in a frame bath is a layered structure, each layer of which performs a specific function:

- A waterproofing layer that protects the floor from moisture.

- Insulation ensures heat retention in the room.

- Vapor barrier, which prevents moisture from penetrating into the insulation.

- Subfloor - it creates the basis for the finishing coating.

- The final coating ensures the aesthetic appearance and durability of the floor.

Mistakes and right decisions

When building a frame bathhouse on stilts, special attention should be paid to the floor structure, especially in the steam room. Wrong choice of materials, insufficient waterproofing and installation errors can lead to serious problems such as wood rotting, mold and reduced heating efficiency.

Insufficient floor waterproofing. The floor in the steam room is exposed to moisture and temperature changes. Neglect of high-quality waterproofing leads to moisture penetration into the lower layers of the floor and its gradual destruction. Solution: the use of high-quality waterproofing materials, such as roll or liquid membranes, which provides reliable protection of the structure from moisture.

Wrong choice of flooring materials. The use of moisture-unresistant materials in the steam room, such as a regular board, leads to their rapid wear and the need for frequent replacement. Solution: choosing materials with high moisture and rot resistance, such as larch or heat-treated wood, which will ensure the durability and safety of the floor.

Inadequate ventilation under the floor. In frame baths on stilts, it is important to ensure adequate ventilation of the underground space to prevent moisture accumulation and mold formation. Insufficient ventilation leads to a deterioration of the microclimate and a reduction in the service life of the structure. Solution: Install enough vents and use vent grilles to circulate air and prevent moisture build-up.

conclusions

Waterproofing the floor in a frame bath plays a key role in ensuring its durability and resistance to wet environments.This is especially important in a steam room, where the humidity level is much higher. The use of high-quality waterproofing materials and their correct installation will protect the floor from water penetration. And they will definitely extend its service life.

Following these recommendations will allow you to independently create a reliable and comfortable floor in a frame bathhouse on stilts. It will serve you for many years, providing comfort and warmth in the steam room.