Pie of water heated floor on concrete, soil, monolithic slab: what materials are needed

The heated floor pie is a multi-layer structure, which generally consists of a base, vapor and waterproofing, the heating circuit itself, and a concrete screed. At the final stage, laminate or other covering is laid. A detailed description of the different types of pies, their structure and features can be found in this material.

The content of the article

Floor on concrete

Despite the peculiarities of different types of construction, a warm floor always contains a number of layers - from the base and the heating circuit itself to the substrate and finishing. Such a system is usually mounted on a concrete slab, as well as on wooden logs. In the first case, 2 options are possible - laying directly on a concrete foundation or on a monolithic concrete slab.

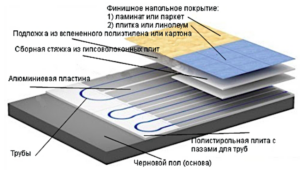

There are different types of circuit (water or electric), but in any case, the cake of a water heated floor on concrete consists of the following layers:

- The basis, i.e. rough floor

- A polystyrene plate with grooves for pipes.

- The actual heating circuit pipes.

- A screed made of gypsum fiber-based slabs (represented in several layers, which is why it is called a prefabricated screed).

- Also, the warm water floor cake contains a substrate. It can be based on thick cardboard or polyethylene that has gone through the foaming stage.

- Next comes tiles or linoleum or other finishing, for example, parquet, laminate.

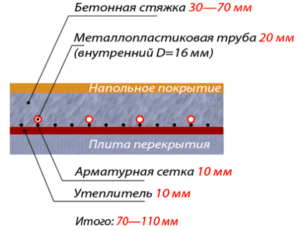

When planning installation work, it is important to take into account not only the sequence, but also the thickness of each layer. The most powerful will be a concrete screed, which reaches 50-70 mm. Next comes a layer of 20 mm metal-plastic pipes. The remaining layers of the pie are approximately the same - 10 mm each. In total it turns out to be about 7-11 cm.

Floor on the ground

The heating system can be laid not only on concrete, but also on a loose base. Then it is necessary to make layers of fine sand or expanded clay. In this case, the underfloor heating pie on the ground will consist of the following layers:

- Geotextile layer.

- Sandy pillow.

- Crushed stone pillow.

- Waterproofing - laid from a roll, and also coated with a special compound.

- Next comes insulation with a special surface that reflects heat.

- Monolithic foundation.

- Next, a reinforced mesh is placed.

- The layer of warm water floor on the ground also contains the pipes themselves.

- Then comes the screed itself.

- The last layer is the finishing layer, i.e. floor covering.

Laying on joists

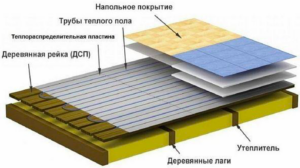

A heated floor on concrete is not much different from one placed on a wooden base. But if the installation is carried out on logs, then plywood is first laid, which will play the role of a base. Next come the logs themselves and the waterproofing film. Insulation material with a minimum thickness of 10 cm is laid in the space between the joists. Heating elements are laid in pre-prepared grooves. Moreover, from the inside, their surface is lined with a special reflective material or foil.

You can also try laying the cake under a warm floor using a flat method. In this case, insulation is also placed in the joists, and chipboard sheets are placed on it. And already channels are cut into them, into which pipes are laid. There is also a slatted technology, when slats are stuffed onto the base.Moreover, the interval between them corresponds to the size of the pipes.

In all the described cases, not too thick plywood is used for the final coating. Next comes the finishing coating, for example, a slab. You can also use laminate, and it is often laid directly on the heating circuit, i.e. without using plywood. Thus, the installation of a warm water floor on a monolithic slab is not fundamentally different from installation on joists, but different materials are used.

Other types of pies

The underfloor heating system has a different design depending on the type of heating circuit. Along with the classic plumbing system, there are also systems based on electricity and infrared radiation. They have several features that determine the structure of the layers.

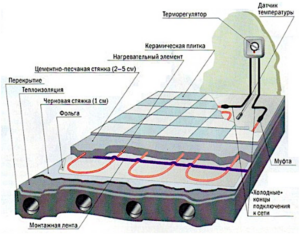

So, a cake for a heated floor in a private house, consisting of electric heating elements, looks like this:

- First comes the concrete slab.

- Foamed polyethylene with a foil layer is placed on it.

- Next comes the screed device.

- They run the electrical cable.

- Film waterproofing is laid on it.

- They make a screed and then lay the floor covering.

When planning the installation of the electrical circuit, you need to take into account that the height of the base will increase. This is due to the need to use foam type polyethylene, its height can be up to 8 cm. In addition, there is a screed on top, its thickness is 3 cm. The cable is placed in it, so its dimensions can be neglected. Thus, the total height will be from 11 to 13 cm.

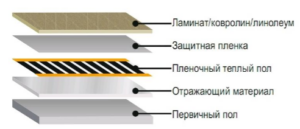

If the circuit is of a rod or infrared type, then the design of underfloor heating on the ground is simpler. The fact is that the film IR heating system is attached under the finishing coating, so installation goes faster. The main layers are:

- Rough screed.

- Next comes the backing.

- Then the IR film material is laid down.

- A layer of vapor barrier is laid on it.

- The last to come are the screed and finishing.

In this situation, the height of the rough screed can be up to 5 cm. Next comes a substrate with thermal and waterproofing, the total thickness of which is only 4-5 mm. The IR film material has a small height, so the total thickness will be 2-5 cm.

Thus, the structure of water floor pies is approximately the same, since there are several common layers. But if you take into account the nature of the base, as well as the features of the contour, the installation technology may differ. When planning, you should take into account not only the characteristics of the materials themselves, but also their total height.