Pressure drop across the restriction device: why do it in a heating system

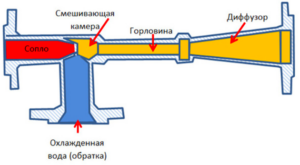

The pressure drop across the restriction device is the difference between the indicator before and after a special element - the elevator. This is a metal part with a nozzle and a mixing chamber, which ensures normal pressure and speed of water movement through all heating pipes. Its structure and purpose are described in more detail in this material.

The content of the article

Why is pressure difference needed?

Intuitively, the pressure throughout the heating system must be the same so that the load is distributed evenly. Indeed, inside all the pipes and radiators of the house the indicator is approximately the same (atm. - atmosphere):

- in a house with one floor 0.1-0.15 MPa (i.e. 1-1.5 atm.);

- in a building with 2-3 floors 0.2-0.4 MPa (i.e. 2-4 atm.);

- in an ordinary apartment building within 10 floors 0.5-0.7 MPa (i.e. 5-7 atm.);

- in high-rise apartment buildings the pressure can reach up to 10 MPa, i.e. 10 atm.

The pressure is constantly monitored by pressure gauges and sensors that are installed in several places in the heating system:

- next to filters, valves, motion regulators;

- before and after circulation pumps;

- in the direction of travel of the central heating system;

- before and after the heating boiler (if the heating system is individual).

It is clear why to create pressure in the heating system - it is necessary to pump water to the house and further to the upper floors.But this also requires a difference in the range of 0.20-0.25 MPa, which corresponds to 2-2.5 atm. Due to this difference, constant movement of water in the circuit is ensured, and at a strictly defined speed. Thanks to this, the pressure difference performs several functions:

- ensuring normal temperature in every apartment, in every room;

- uniform flow of water;

- prevention of strong changes and accidents;

Pressure drop and restriction device

The pressure difference is ensured by installing such an important element as an elevator in several places in the heating system. This is a metal part that mixes hot and cooled water (the first flows through a straight pipe, the second through a reverse pipe, i.e. return).

As can be seen in the figure, the elevator consists of several elements. The principle of its operation is this. A hot stream of water moves from the boiler room or thermal power plant and enters the nozzle (indicated in red). This is a narrowing device that increases water pressure, creating the necessary difference of 2-2.5 atm.

As the nozzle passes, the pressure increases abruptly, water enters the mixing chamber, where cooled liquid also flows through the return line. Thanks to this, the coolant is cooled to the required temperature and then flows through the neck into the diffuser chamber, and then into the apartment. Thus, the elevator performs 3 important tasks - it provides:

- the desired temperature;

- required pressure;

- a certain speed of water movement.

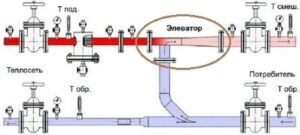

Elevators are installed immediately before water flows to the consumer.

From this review it is clear why pressure is needed in the heating system, as well as the purpose of the restriction device.It is this that creates the necessary difference, which ensures a certain speed of water flow. As a result, each apartment receives the same amount of heat, and approximately the same pressure is maintained inside the circuit.