Do-it-yourself stove for a long-burning greenhouse: how to make it

A stove for a long-burning greenhouse is usually made from a metal barrel. A hole is cut in it for the chimney and combustion chamber, the legs and pipe are welded, and a partition is installed. The device operates by smoldering sawdust, which is supported by firewood burning from below. How to make such a stove yourself is described step by step below.

The content of the article

Where to put the stove

First of all, you need to decide on the location of the stove. Since the soil should warm up as evenly as possible, it is better to place the structure in the very center of the greenhouse. This is the place equidistant from each corner, i.e. at the intersection of diagonals.

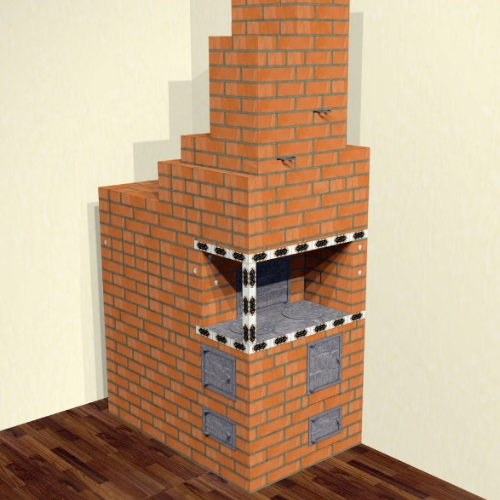

It also happens that part of the floor is tiled, and the walls are brick (along the perimeter). This finish provides greater safety, so you can place your own stove for a long-burning greenhouse on a tile. Even if it stands close to the wall, this will not affect the heating efficiency.

But at the same time, it is important to extend the chimney pipe so that it is as far as possible from the stove and goes up the entire length. This is necessary to ensure that carbon monoxide and other combustion products are completely removed to the street. It is also important to take into account that the length of the chimney should not exceed 5-6 m - otherwise the removal will not be as effective.

Furnace structure

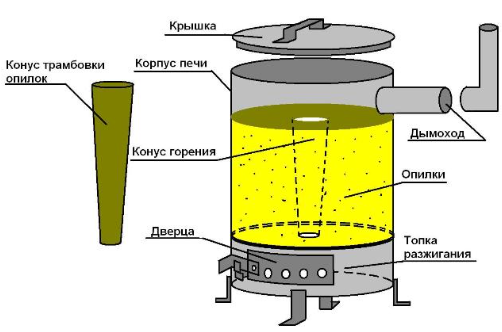

The greenhouse is heated with wood in a stove, the basis of which is the combustion chamber. It can have either a square or round shape. The main requirement is that the compartment must be sealed (except for the hole for the chimney) and covered with a tight lid on top. In the upper part, a hole must be made for a pipe that removes gases.

A door with a blower is installed in the lower part, which provides the necessary draft. As a rule, sawdust is used for long burning, not firewood. Therefore, it is necessary to provide a special cone for compaction, as shown in the diagram.

The operating principle of the furnace is as follows:

- Cold air enters through the blower door, but it flows rather slowly due to the large mass of sawdust.

- As a result, the material will not burn, but smolder, providing precisely a long-term supply of heat.

- Carbon dioxide, carbon monoxide, and soot are discharged into the chimney located in the upper part.

- Thanks to the design features and the large amount of sawdust, combustion is ensured for several hours (from 8-10 to 24).

Step-by-step instruction

The easiest way to make a stove is from a metal barrel with a volume of 200-250 liters. To work, you will also need a metal pipe with a diameter of 15 cm (future chimney) and metal corners. You need a welding machine with electrodes and a grinder with a corresponding disk.

The assembly instructions consist of the following steps:

- Carefully cut off the top part of the barrel and polish the edges. There is no need to throw away the circle - it will be useful as a sawdust press.

- Cut a hole for the chimney after making the necessary measurements.

- In the lower part, mark and make a hole for the blower.

- They draw up a drawing and make a drawer into which the ash will fall.Instead, you can simply install a door that will ensure tightness.

- A metal cone is made, the smaller diameter of which is 8 cm, and the larger one is 12 cm.

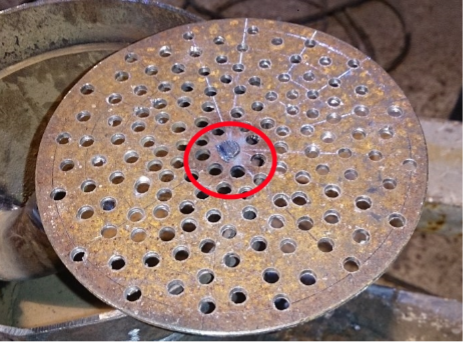

- Cut out a circle slightly smaller in diameter than the barrel. Numerous holes are made in it. In this case, the central hole in diameter should coincide with the smaller diameter of the cone (8 cm). This partition will divide the combustion chamber into 2 halves - firewood will lie below, and sawdust will lie on top.

- From the cut off upper part (barrel lid) a disk is created, the diameter of which is slightly smaller than the diameter of the barrel. Plates are welded to it from below, as shown in the photo. This is a press that will gradually compact the smoldering sawdust and prevent the access of a large volume of air. It is desirable that it be weighty - a cast iron circle is ideal.

- Next, the chimney pipe is welded.

- Mount the legs.

How to use the stove

Since this is not an ordinary device, but a long-burning stove, it is necessary to clarify how it will work. The instructions are quite simple:

- Turn the cone over and insert the smaller end into the septum, as shown in the photo.

- Sawdust is poured into the upper half of the chamber and compacted. The denser the material is, the longer the combustion will be. Moreover, the compartment should be filled to a maximum of two-thirds of the volume. It is important to understand that you cannot open the lid during combustion and add new sawdust - first you need to wait until it burns out completely.

- Remove the cone and you get this “tunnel”.

- They put several firewood with small chips in the firebox. They make a fire.

- When the wood is completely burned, the sawdust begins to smolder. At this moment, you need to adjust the draft correctly so that the air flow is not too large (leave it slightly open).

- The top of the stove is covered with a lid. If the combustion is weak, you can leave a small gap.

Such a stove is capable of heating a medium-sized greenhouse for one day. But it is important to learn how to regulate combustion. On the one hand, the sawdust should simply smolder, but it should not fade away either. In the first hours, it is recommended to carefully observe how the fire behaves. If necessary, the draft is reduced or increased using the blower cover and door.