Do-it-yourself vegetable pit made of concrete rings in the garage: how to make it

One of the simplest ways to create a cellar is to install a concrete ring. In this case, the walls have already been formed, so all that remains is to make the floor and install a ceiling with a door. However, you will have to dig a vegetable pit from concrete rings yourself, since an excavator will not be able to drive in. The pros and cons of this technology and how you can implement it step by step are described in this material.

The content of the article

Pros and cons of concrete rings

You can build a cellar yourself by digging a pit and finishing its walls from the inside. But then the question arises of how to dry the vegetable pit in the garage in order to maintain a normal microclimate. To simplify the task, it is recommended to use concrete rings, which have tangible advantages:

- serve for a very long time - at least 20 years;

- do not collapse under the influence of moisture, light or temperature changes;

- resistant to soil pressure from the sides;

- easy to install - essentially, you just need to dig a hole, level the base and place the block.

On the other hand, if you are making a vegetable pit in the garage with your own hands, you need to take into account the features of concrete rings and their disadvantages:

- the weight is very large, so a truck crane is required;

- concrete can be severely damaged upon impact, so loading and unloading as well as installation work must be performed very carefully;

- In order for the ring to last as long as possible, you will need to install heat and waterproofing.

How to build a cellar: step-by-step instructions

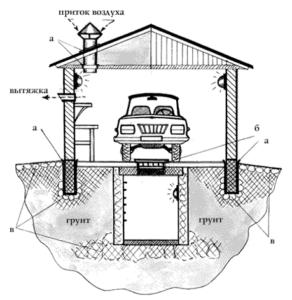

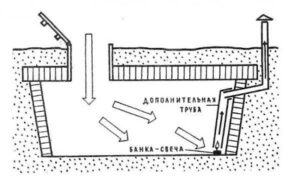

A pit for storing vegetables is constructed in several stages. Essentially, this is a pit in which a concrete block is installed. Moreover, the cellar has a reliable lid, and in the garage they must make a hole in the wall for exhaust and in the ceiling for fresh air, as shown in the diagram. Ventilation of a vegetable pit is most often done using natural technology. Although, if there are concerns about the safety of vegetables or high humidity, it is worth making a forced system with a built-in fan.

Pit

Instructions on how to make a vegetable pit begin with creating a pit. They dig it out by hand, since an excavator will not be able to enter the small space of the garage. In this case, the perimeter of the cellar is determined so that it is slightly smaller compared to the main building, so that the structure is durable.

It should be taken into account that groundwater often occurs on the site. To ensure that your own vegetable pit in the garden is dry, you should take care of a pump for pumping out liquid in advance.

Pit waterproofing

Even if there is no groundwater nearby, care should be taken to install waterproofing. It is needed in all cases, even if you made a vegetable pit out of brick with your own hands. To lay bitumen or other material you must:

- Thoroughly compact the bottom.

- Cover with clay (layer height 5-7 cm).

- Moisten it with water.

- Compact again until the surface is as dense as possible.

Floor

A do-it-yourself potato pit is built only on a flat floor, so special attention must be paid to its arrangement. The recommended procedure is as follows:

- Place sand 4-5 cm high on the clay layer.

- Tamp down thoroughly.

- Fill in the crushed stone and compact it again.

- Next, prepare the concrete mixture and screed in one go.

- In order for a DIY vegetable pit made of concrete to have a normal floor, you need to fill a layer with a height of 15 cm (optimally 20-25 cm).

- The surfaces are smoothed as thoroughly as possible, but even if small differences remain, they can be eliminated.

- Next you need to level the floor with cement-sand mortar.

- Understanding how to set up a vegetable pit is not difficult. The beacons should be placed directly along the screed; their height is only 1.5 cm. The beacons are leveled using a regular building level.

- After finishing is completed, the surface is leveled using a foam float.

Walls

Making a high-quality floor is important, but this is not the only requirement for a hole for storing vegetables with your own hands. The ventilation system is pre-arranged, as shown in the diagram.

Next, they build the walls themselves, proceeding as follows:

- The formwork is formed based on the fact that the wall thickness will be about 20 cm. Moreover, it should be located at a short distance from the slope of the pit (4-5 cm). They install plywood and support them with boards.

- A do-it-yourself potato storage pit must have reliable walls. To do this, install a strapping of reinforcement elements (metal rods) directly inside the formwork.

- Concrete is mixed (the composition is similar to that used for the floor) and poured in several approaches - a third, two-thirds and the last layer.

- Wait until the concrete dries (about 2 weeks) - this is necessary so that the waterproofing of the vegetable pit from groundwater does not contain moisture. Then the formwork is removed.

- The space between the slope and the wall surface is filled with sand and compacted - thanks to this, the burial pit will not freeze.

Ceiling

The next stage is the construction of a monolithic floor with a hatch. The step-by-step instructions are as follows:

- Rolled T-type metal or railway rails are laid (the interval between them is from 60 to 100 cm).

- Boards for formwork are placed below.

- Metal beams are fixed with strong strapping (reinforcing rods will be needed).

- Assemble the welded frame for the door.

- Prepare the concrete mixture and pour it into the formwork in one go, so that the height is at least 20 cm.

- Wait several weeks for the concrete to dry completely.

Waterproofing and finishing

Now you need to think about how to insulate the vegetable pit, finish it and lay waterproofing. They start by removing dust. Then all joints between the surface of the walls and the ceiling are primed and covered with mastic. Next, roofing felt is laid, which will serve as waterproofing. As for the insulation, you can use mineral wool and lay wooden or plastic lining on top of it.

Thus, each stage of construction can be completed independently. It is best if a small team of at least 2 people works. All work is done with your own hands, but the concrete is mixed using special equipment, which can be rented, or you can order a ready-made mixture.