Installation of partitions from tongue-and-groove slabs: how to lay blocks and attach them to the wall

Installation of partitions made of tongue-and-groove slabs (GGP) is carried out in several stages. First you need to prepare and level the surface of the floor and wall. Then glue the cork tape onto which the first one is installed. Subsequent rows are mounted in the standard way, sticking the ridges of one part into the grooves of another. Step-by-step instructions with photos can be found in this article.

The content of the article

Types and sizes of slabs

Tongue-and-groove slabs are a common type of building material that is used only to create an interior partition, for example, to separate a toilet or a room with a shower. The name of the material is associated with the presence of grooves and ridges at the ends, through which they are connected during installation (similar to a construction set).

When understanding how to lay tongue-and-groove slabs, you need to keep in mind that there are 2 main types of material:

- standard, which are used in rooms with normal humidity levels;

- moisture-resistant, which are used, for example, in the bathroom or kitchen.

The laying of tongue-and-groove blocks is carried out by dividing the materials into 2 categories depending on the structure:

- Hollow – have cavities inside, are very light, so they put little pressure on the floor. They are easy to install, allow wiring and other communications to be installed inside, but at the same time do not provide good sound insulation.

- Full-bodied They have no internal cavities and are a monolithic material. The principle of the instructions on how to lay tongue-and-groove blocks of this type is similar. However, they have more weight and carry a load on the floor. At the same time, they protect well from noise and allow you to hang cabinets, shelves and other structures.

Another important classification is related to the composition of the material:

- Gypsum boards are affordable, but are not highly resistant to moisture. Therefore, their use is limited to ordinary rooms, for example, living rooms.

- Silicate rocks consist of quartz sand and lime. They can even be used in rooms with high humidity levels, such as the bathroom.

When planning to learn how to lay a tongue-and-groove ridge, you also need to familiarize yourself with the dimensions of the material. The slabs have a rectangular shape with a width from 199 to 500 mm and a length from 500 to 900 mm. As for thickness, it usually has one of three values: 70, 80 or 100 mm.

Installation technology

Typically, tongue-and-groove blocks are laid with your own hands, since the technology is simple and does not require special equipment. Essentially, the work is the construction of a wall, so first the base is prepared, after which each row is built step by step. The main stages are:

- The substrate for the PGP is prepared - cement or concrete screed. To do this, first determine the differences in the floor. If they are less than 20 mm, you can simply make a cement screed; if within 40 mm, you will also need reinforcement. If the defects are significant, concrete should be used.

- In order for tongue-and-groove partitions to stand level, prepare the base - the floor, and also clean the surfaces of the walls from dust and prime them; if necessary, dismantle the old screed and begin marking using a laser level. Then mix the composition and lay a new screed.

- The blocks are not placed immediately - first an elastic gasket for tongue-and-groove slabs is glued to the floor. Most often, cork tape is used, which compensates for impact noise and deformation under the influence of temperature.

- The PGP is glued to this tape and additionally secured with fasteners. It is recommended to perform a “soft” dressing using steel corners 100*100 mm or direct hangers for a plasterboard profile. Rigid fastening will not work, since walls made of PGP are deformed due to the temperature difference with the outer wall and can become cracked if the contact is too tight.

- Next, the installation of PGP Knauf or another brand begins. The first row is being erected, and the installation is carried out from the wall. The slabs are fixed to the cork tape with gypsum glue, applying it to horizontal and vertical surfaces. The last element is adjusted to size.

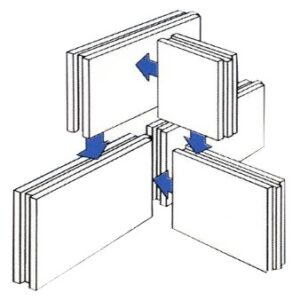

- As already mentioned, tongue-and-groove slabs are fastened to the wall using steel corners. The second row is erected with slight mixing (minimum interval 10 cm). At the same time, bandaging is observed both at the corners and at the partitions, inserting grooves into the ridges, as shown in the diagram.

- Jumpers for tongue-and-groove partitions of the next row must completely cover the seams of the previous one, i.e. installation is carried out like brickwork. Corners are placed on the outer corners and treated with putty. The inner corner must be reinforced with serpyanka.

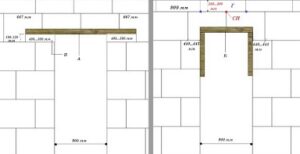

- Next, proceed to the installation of the doorway.If it is small (up to 90 cm), a lintel is made from the same blocks. A wooden support is first placed in the span, which temporarily holds the slabs until the glue hardens. If the opening is wider than 90 cm, install a permanent lintel from metal corners or wooden beams.

- At the final stage, the last row of blocks is placed, adjusting them in size depending on the distance to the ceiling. The connection to the ceiling is carried out with suspensions in the same way as it was with the floor.

Thus, you can install a partition made of tongue-and-groove slabs in a matter of hours. First you need to prepare the surface, then connect the first row to the floor, and then lay out the subsequent rows. If necessary, wiring is laid inside the wall, having previously made grooves.