Dowel-nail: dimensions

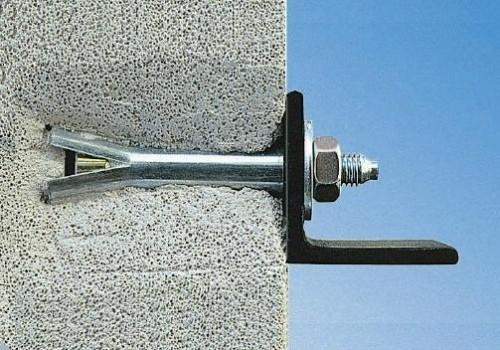

A dowel-nail is a type of fastening material. It has two parts: the nail itself (with or without threads) and the body (usually plastic). Used in construction. Thanks to the special design, when the spacer part expands when screwed in, it provides much better fixation.

The content of the article

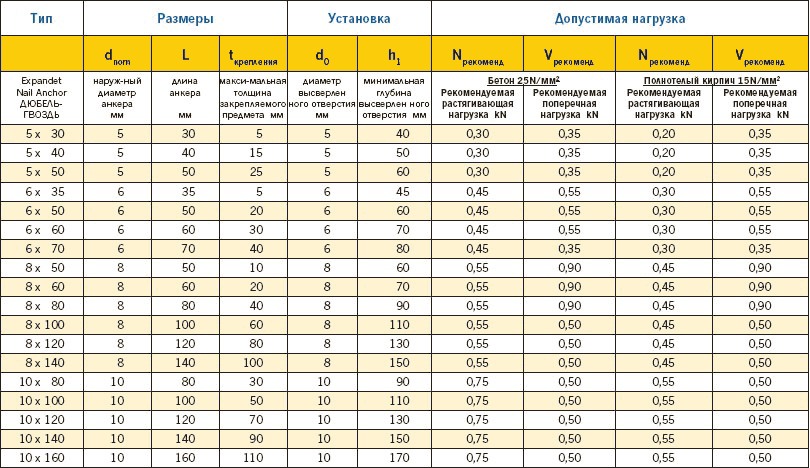

Dowel nail size chart

The fastener is very easy to use: you first need to make a hole, install it and hammer it in with a hammer.

According to established standards, they are manufactured with a diameter of 5, 6, 8, 10 mm and a length from 20 to 150 mm. Sometimes 4 mm fasteners are available. Their size must correspond to the design parameters. Marking is applied to each unit. The symbol is the diameter and length of a specific product (for example, 4*20, 4*40).

The required parameters for all types can be found in the table.

Fastener classification

Choosing the right type of fastening is a responsible task. First you should consider some features:

- the load force on the structure, its surface and the nail itself;

- pressure characteristic;

- types of fastening;

- processed material;

- surface location.

Exists many types of dowels, suitable for different designs.

By installation type

Due to the varied structure of nails, tools are used to work with them. Dowels with threads are hammered or screwed in. If a mistake is made, it can be easily dismantled.An unthreaded nail can only be driven in with a hammer and cannot be removed.

Using a construction gun allows you to speed up the work. Installation is carried out by screwing in a nail with a limiter.

By surface material

Very strong - nylon, Suitable for processing standard stone. With a diameter of 2–16 mm, they can withstand loads of up to 400 kg.

Other varieties:

- With spiral ribs for concrete.

- Reinforced spacer.

- T-dowel (for fastening shelves, furniture).

- With cutters and screw ribs - for drywall.

- Driva – for cables, skirting boards, wiring.

- Butterflies - for the heaviest objects. The point is that when hammered, the wings open, facilitating a strong fixation.

- Mushroom – securely and neatly holds foam and other fragile materials.

- Facade – for hollow materials.

- Clamps – fastening wires to walls.

- For decoration and light objects.

The wrong choice of fastening will ruin the work done.

Specifications

Manufacturing rules documented only for expansion dowel. They are made from specialized metal of classes BK and KK grade 70. They must undergo heat treatment. Their hardness and curvature must correspond to the established indicators. Each unit is coated with a layer of zinc to protect against corrosion.

Based on one document, other varieties are produced.

Dowel-nails – indispensable material for repair work. If you study their general characteristics and types, then choosing the right material for the job will not be difficult.