Laying heated floors under laminate

Of course, every owner of his apartment wants the interior to always be warm, cozy and comfortable. Consequently, various types of insulation directly under the floor covering are in great demand. In this article, we will analyze which ones are most profitable to purchase and which ones should be abandoned. In addition, we will consider the entire process of laying laminate flooring.

The content of the article

Is every laminate suitable for heated floors?

Of course, this will depend on some factors. There will always be an object that will be relatively more suitable for a given case. Thus, it is best to pay attention to the markings. It is this that allows you to determine the quality offered by the manufacturer.

Accordingly, not every laminate is compatible with floors whose temperature is plus. The interval of the recommended degree should be located with the mark in the instructions.

What kind of warm floor is suitable for laminate

Thanks to modern production, today you can see that almost every laminate is able to approach the surface. However, there are exceptions everywhere: there is such material that is of average quality and its thickness is about 6 millimeters.Thus, we will analyze the rest separately below in the article.

Water heated floors

First, you should clarify the principle of operation and the specifics of manufacturing. The device consists of pipelines that are laid in a screed. They themselves are located parallel to each other directly under the floor covering. They are also connected to the heating system. High temperature water passes through it. Moreover, this shell has a fairly thin texture, which increases the risk of danger. Consequently, there are certain restrictions on operation both in private and multi-storey buildings. As for the coolant, it performs the function of heating the air.

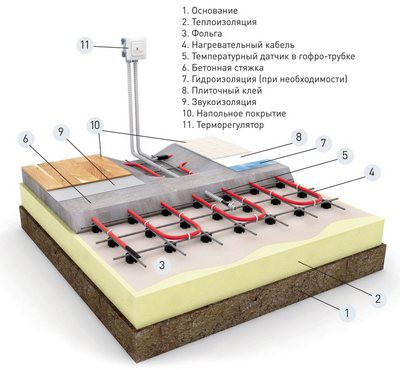

Warm floor with heating cable

Compared to the previous version, this one uses the simplest installation. This is explained by the fact that this design is made in the form of a cable. It heats up when an electric current passes through it. Actually, the measurements in which electricity appears are indicated in kilowatts. Due to this, users should first think before purchasing: is it worth activating the equipment once again or is it best to save money in this case. Installation, in turn, is carried out during the repair process in a few hours, and a major one. Do this in a fairly thick layer of screed. After which it can immediately be used for its intended purpose. Naturally, the floor level rises by several millimeters. This usually ranges from three to four units. In addition, the power can be adjusted by changing the laying step.

Compared to the previous version, this one uses the simplest installation. This is explained by the fact that this design is made in the form of a cable. It heats up when an electric current passes through it. Actually, the measurements in which electricity appears are indicated in kilowatts. Due to this, users should first think before purchasing: is it worth activating the equipment once again or is it best to save money in this case. Installation, in turn, is carried out during the repair process in a few hours, and a major one. Do this in a fairly thick layer of screed. After which it can immediately be used for its intended purpose. Naturally, the floor level rises by several millimeters. This usually ranges from three to four units. In addition, the power can be adjusted by changing the laying step.

Infrared film heaters for laminate flooring

Speaking of appearance, it is worth noting that it is provided in the form of a really thin film. It contains certain metals within itself, which, therefore, have the ability to emit infrared waves at the moment while an electric current passes through them. Installation in terms of simplicity is similar to the previous copy. You just need to lay it on the floor covering.

Electricity costs will be minimal, especially compared to electrical equipment. Currently, such a high demand for such a purchase can be explained by the ability to regulate the temperature using a wi-fi network. This truly provides significant convenience. In addition, such remote control via the Internet adds to the popularity of the device.

REFERENCE. There is even a special application for control on both Android and IOS. The thermal film itself has marks to indicate the location of the future cut. This makes it easier to mount in different areas of the surface with any configuration. In conclusion, it is worth clarifying that installation can be done at any time.

Do-it-yourself installation of heated floors under laminate

Of course, this is not an easy matter. That is why below we will touch upon not only the most important aspects, but even seemingly insignificant points, which are also important in the process itself. Moreover, based on the above information, we can conclude that installing a film coating is the most profitable and expedient. This is not only due to the ease of installation, but also based on the main advantage - saving electrical energy and due to the convenience of temperature regulation. Therefore, further we will consider exclusively the presented installation option.

Necessary materials

At the time of screeding, you will directly need certain items. All of them are recorded in the list below:

- Rolls of infrared film. The main thing is that they are not made of aluminum foil, as they are not at all suitable for use.

- Laminate with a special backing.

- Scotch tape to secure the material.

- Thermostat, and with a sensor.

- Polyethylene film.

- Thermal insulation. It is better if it is metallized.

How to make a warm floor under laminate - algorithm

So, when all the tools and products are ready, you can begin the main process - installation. Below is a list of tasks in the required sequence that must be completed to achieve results.

- The first thing to start with is preparation. First, eliminate possible obstacles, namely, remove unnecessary items from the workplace.

After which you can start leveling the surface. The way you will do this depends directly on the current state of the concrete space itself. If small irregularities are identified, you can use the pouring method, when, accordingly, a condition is created for pouring the mass into the holes. In addition, with uneven slabs, screeding is possible. As for the general meaning of this procedure, it is the need to guarantee that the various elements inherent in a warm floor will not be damaged by defects in the main coating. Otherwise, the material will lie unevenly.

After which you can start leveling the surface. The way you will do this depends directly on the current state of the concrete space itself. If small irregularities are identified, you can use the pouring method, when, accordingly, a condition is created for pouring the mass into the holes. In addition, with uneven slabs, screeding is possible. As for the general meaning of this procedure, it is the need to guarantee that the various elements inherent in a warm floor will not be damaged by defects in the main coating. Otherwise, the material will lie unevenly.- Next, you need to arm yourself with tape and cover the backing end-to-end. Finally, secure them with the product. As a result, you should have a floor where everything is covered, so to speak, with a sheet of thermal insulation.

- After completing the “preparation” stage, you can smoothly move on to the screed.Laying is carried out in the prepared space. Therefore, heat-reflecting material must be laid in separate pieces.

- The installation itself is performed in rows, and its connection is parallel. The contacts are attached next to the copper strips, and are fixed with insulation, bitumen at that.

- Then sensors are installed with which you can regulate the temperature. It is their connection that is carried out directly into the layer.

- Next, the wires are connected to the regulator. How exactly this is done should be indicated in the instructions that are included with the purchase of the device.

- The very last step is testing. This stage is important in the entire procedure. Thanks to it, various shortcomings are identified that need to be eliminated immediately.

As you can see, the whole process of laying a water floor is simple, so anyone can do it.