Installation of warm electric floor under tiles

Ceramic tile floor — an interior element that successfully complements the style of the room and also helps create a comfortable atmosphere. This finish differs from other materials in its moisture resistance and durability. In addition to advantages, ceramic products also have disadvantages: a smooth surface can cause injury, and it is not very pleasant to be on a constantly cold floor, especially barefoot. To make the surface warm, heating elements are placed under the tiles, which make the coating warm and pleasant to use.

Ceramic tile floor — an interior element that successfully complements the style of the room and also helps create a comfortable atmosphere. This finish differs from other materials in its moisture resistance and durability. In addition to advantages, ceramic products also have disadvantages: a smooth surface can cause injury, and it is not very pleasant to be on a constantly cold floor, especially barefoot. To make the surface warm, heating elements are placed under the tiles, which make the coating warm and pleasant to use.

The content of the article

Is it possible to lay an electric heated floor system under tiles?

Manufacturers of electrical heating systems recommend installation specifically for ceramic finishing. This is due to the high thermal conductivity of the material and heat transfer ability. But to lay heated floor heating elements, there must be initial conditions that allow this work to be completed:

- the height of the floor should be increased by 2–5 cm, and this is not always possible, especially with partial renovation of the room, since large differences in heights between rooms arise;

- availability of the required amount of electricity with a grounding wire;

- absence of other communications (heating pipes or water supply) in the area that is planned to be heated, becausethe magnetic field of heating elements can destroy utility networks;

- the possibility of installing thermal insulation to retain more heat on the surface.

ATTENTION! Installing thermal insulation will require increasing the height of the base! The use of modern heat-reflecting films based on foil will preserve the thickness of the screed.

Types of electric floor

The difference between an electric system and a water system is the absence of coolant liquid and pipes that are installed under the finishing material. Electric floors heat up by converting voltage into thermal energy. They differ in appearance, depending on their design features:

- using a heating cable;

- heating mat;

- infrared heating film.

The cable used for heating can be single-core or two-core. This feature affects the electromagnetic field that the wire creates when connected. It is believed that it is single-core and emits harmful waves, so it is not recommended to use it in residential areas. Depending on the power of the heating element, manufacturers recommend laying it at intervals that allow the required area to be heated. The cable is installed in a concrete screed, regardless of the finishing material of the floor.

The heating mat is a polypropylene mesh (sometimes with a film), similar to reinforcement for plastering work. A low-power cable is attached to this grid and is connected to the network. Such mats are installed in the upper part of the concrete screed when finishing with linoleum or laminate. When laying tiles - in an adhesive solution, the thickness of which is increased depending on the size of the mat used.

The infrared heating element is a double film, inside of which there is a material that converts current energy into heat. Manufacturers use for this purpose a special paste or similar raw materials that have the same properties. At the edges of the polymer film there are wire leads to which a film-type heater is connected.

REFERENCE! Any of the varieties of electric heating systems can be equipped with a regulator and temperature sensor!

How to properly install a cable floor system

Installing a heated floor cannot be called a simple job, but it is still quite feasible. If desired and have the skills to use construction tools, anyone can do this work with their own hands, following the following procedure:

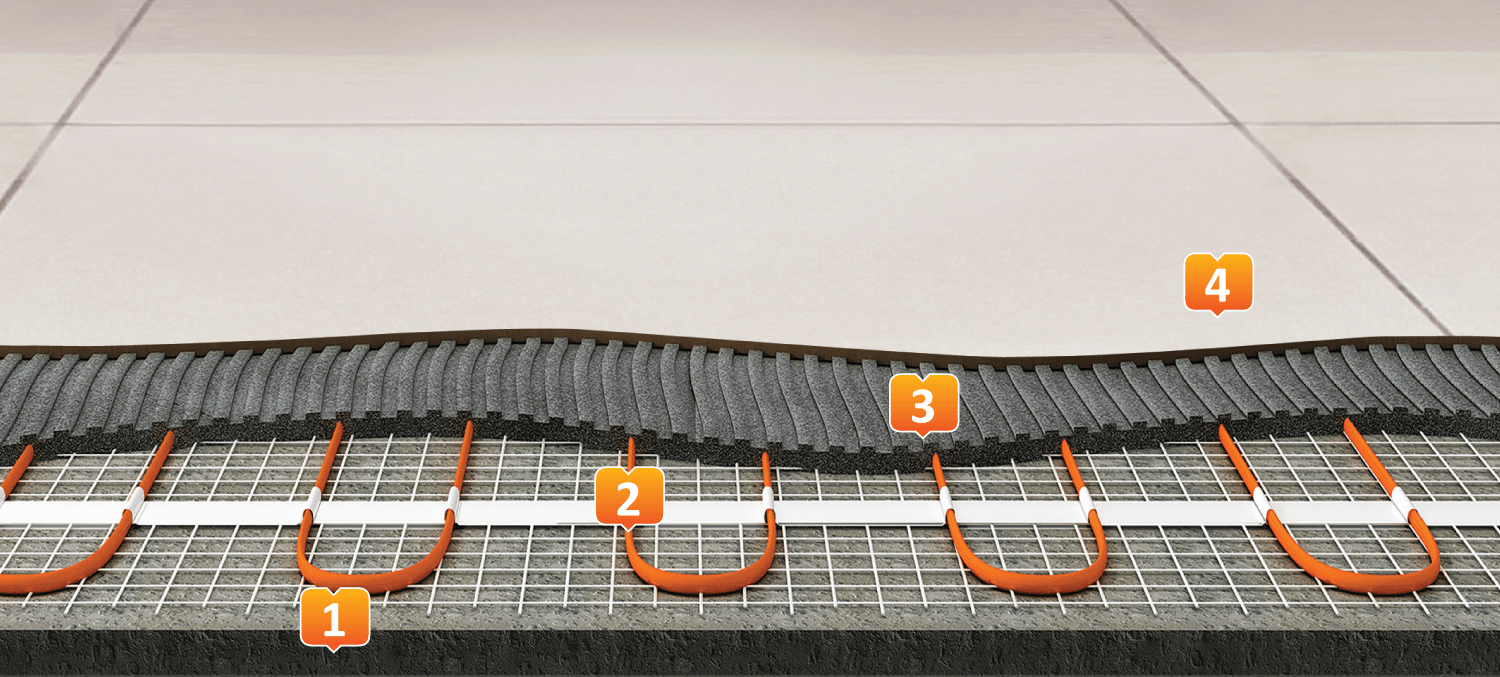

- First of all, clear the room of furniture and old flooring. Depending on the purpose of the room, the floor is waterproofed partially or only at the joints of the floor slabs. Then the base is leveled, if necessary, a concrete screed of 1–3 cm is made.

- After this, thermal insulation material is laid, which will not allow heat to “escape” to the lower part of the floor. Expanded polystyrene, penofol or other raw materials with a high thermal conductivity coefficient are used as an insulator. This material is laid on an adhesive composition, the joints are fixed with the same mixture or in another reliable way.

- After this, they select a place to install the thermostat and make a groove in the insulating layer and the wall for the corrugated tube into which the temperature sensor will be inserted.

- To increase the strength of the screed, a reinforcing mesh is laid on top.In accordance with the manufacturer's recommendations, roll out the cable over the area of the room in which installation is being carried out. Depending on the thickness and power of the heating wire, the laying step recommended by the supplier ranges from 8 to 25 cm. The optimal distance between the cables is considered to be 12–15 cm. The coil is rolled out like a “snake” over the floor surface and secured with ties to the reinforcing mesh.

- Lay the corrugated tube for the sensor with the largest bending radius between the horizontal and vertical planes. The sensor should be located in the middle, between the heating wires.

- After this, pour a 2–5 cm concrete screed or self-leveling floor, check the quality of the surface, then allow it to dry for at least 3 weeks.

- Install a temperature sensor, connect the cable to the network and check its functionality.

IMPORTANT! The design features of the wire affect the installation method. If the heating element is single-core, then the end of the warm winding paths should converge with the beginning for connection. When laying a two-core cable, it doesn’t matter where the cable ends.

Now finishing is done using tiles or other material.

How to lay tiles on a warm floor

A feature of installing tiles on a finished screed is:

- the use of a damper tape that allows the tile to take a “floating” position when heating and cooling;

- the use of special adhesive compositions, which, in addition to strength, have elasticity, which helps maintain the integrity of the seams during operation.

ATTENTION! The damper tape is laid out around the perimeter of the room with heated floors. Its installation can be done while making a screed, which makes it easier to join ceramic products with the tape.

The use of heating mats will simplify the installation of tiles. Such a heating element is placed directly under the finishing material and fixed with an adhesive composition on which ceramic products are laid.

Having studied the procedure and features of the work on installing tiles on a warm floor, we proceed to installing the floor and laying ceramics.