Laying parquet boards

Parquet boards are one of the most popular materials for floor finishing. It gained its popularity not only due to its aesthetic appeal, but also due to its quality characteristics. The process of laying parquet boards is simple and does not require special qualifications; even an amateur can lay it.

The content of the article

Laying parquet boards with your own hands - technology features

Installing parquet flooring yourself will help significantly save the budget allocated for repairs. To do this, you need to study the main points of technology and be able to handle tools. In order for the coating to last for many years, it is important to know some nuances of how to install it correctly:

It is not recommended to lay boards in rooms with high air humidity and operational load (bathroom, toilet, corridor).

It is not recommended to lay boards in rooms with high air humidity and operational load (bathroom, toilet, corridor).- The key to successful work is careful preparation of the base. The surface must be smooth, without cracks or damage. They also make a substrate of two layers.

- Before installation, the material should lie in the room for about two days.This is especially important to do in the winter season, when the difference between the temperature indoors and outdoors is significant. In this case, it is better to remove the boards from the packaging film.

- Place the boards in the direction of the flow of natural light. This will visually hide the joints of the rows.

ATTENTION. Before starting work, you need to choose a laying scheme and calculate the required amount of material. It is necessary to know the dimensions of the boards of the last row, since in most cases they have to be cut.

Necessary tool

No special mechanisms are required, and they are easy to find in almost every home. Let's look at the main devices:

- hacksaw or jigsaw;

- plastic block for padding;

- spacer wedges;

- rubber mallet;

- screwdriver;

- tape measure and triangle;

- clamp.

Step-by-step instruction

Read on to learn how to properly lay parquet boards. It should be noted that the process differs from laminate and parquet flooring. Follow the instructions and recommendations provided in this article.

Preparing the subfloor

Before installation begins, check the subfloor. It can be either wooden, concrete or tiled. The permissible maximum height difference should be 1–3 mm per linear meter. A moisture meter is used to measure humidity. It should be within 2–3%.

If the base has uneven surfaces, then special dry mixtures should be used. Each defect must be eliminated, and if necessary, a new screed must be poured. If the floor is wooden, then sand it or completely refinish it. Installation on moisture-resistant plywood is recommended.

IMPORTANT.It is recommended to lay the boards at a room temperature of 20–25 degrees and a humidity of 40–60%.

Preparing to lay the coating

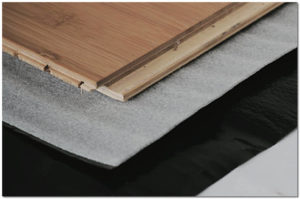

Before starting work, the base is inspected again and vacuumed. After all, any pebble, even a small one, can damage the coating. Laying materials on a substrate is mandatory. They also make high-quality waterproofing to improve thermal insulation characteristics. Thanks to the backing, the boards will be able to move slightly relative to the base. This, in turn, will avoid damage to the material due to different expansion under the influence of external factors. To reduce humidity, use a vapor barrier film or primer. The film is spread in strips with an overlap of 15–20 cm. It is placed on the walls up to 5 cm high. Next, the substrate is laid on top. The strips are connected with tape. The distance between the wall and the heat insulator should be up to 1 cm.

Before starting work, the base is inspected again and vacuumed. After all, any pebble, even a small one, can damage the coating. Laying materials on a substrate is mandatory. They also make high-quality waterproofing to improve thermal insulation characteristics. Thanks to the backing, the boards will be able to move slightly relative to the base. This, in turn, will avoid damage to the material due to different expansion under the influence of external factors. To reduce humidity, use a vapor barrier film or primer. The film is spread in strips with an overlap of 15–20 cm. It is placed on the walls up to 5 cm high. Next, the substrate is laid on top. The strips are connected with tape. The distance between the wall and the heat insulator should be up to 1 cm.

Selecting a substrate

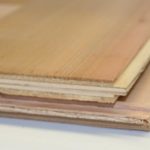

Construction hypermarkets offer a wide range of substrates. Before making a choice, it is necessary to clarify their compatibility with different types of boards. Let's consider the main ones:

Soft materials such as cork and polyethylene foam are easy to install and have low cost. And in combination with foil they are highly resistant to moisture. However, they can sag quickly.

Soft materials such as cork and polyethylene foam are easy to install and have low cost. And in combination with foil they are highly resistant to moisture. However, they can sag quickly.- Cork masks flaws well and has good sound insulation. The floor will not creak or deform.

- Expanded polystyrene is environmentally friendly, holds its shape well and is not affected by insects.

- Coniferous substrate is new in the construction industry. It is made from natural ingredients, environmentally friendly and water resistant. The main disadvantage is the high cost.

Recently, special underlays for laminate flooring, which can be bought in hardware stores, have become increasingly popular. But using carpets, carpet and linoleum as a substrate is extremely undesirable. These materials can become deformed and pull parquet boards along with them. In addition, old coatings have already absorbed unpleasant odors that are unlikely to be hidden.

Methods for installing parquet boards

There are several options for attaching the board: floating, using additional fasteners, and using glue. Each of them has its own characteristics. The choice of installation depends on the type of locking system. The packaging must contain detailed instructions and relevant diagrams.

Floating installation

This method is the most common. It is also called independent. The surface is assembled with its own locks and is not fastened to the base. However, it is relevant if the thickness of the die does not exceed 14 mm. Laminate flooring is installed in the same way. The good thing about this method is that if mistakes were made in the installation, they can be corrected. Follow the following sequence of actions:

The board is laid along the longest wall in the direction from left to right. At the same time, the part of the locking connection facing the wall is removed from it.

The board is laid along the longest wall in the direction from left to right. At the same time, the part of the locking connection facing the wall is removed from it.- The surface should be 15 mm away from the wall. To do this, assemble three rows, place wedges and pull the canvas into the desired position. Each subsequent row is laid with a shift.

- Subsequent rows are assembled sequentially, tapping with a rubber hammer.

- Difficulty may arise on the last row. It is important to remember to leave space to compensate for thermal expansion.

- Then the wedges are removed and installation of baseboards and door thresholds begins.

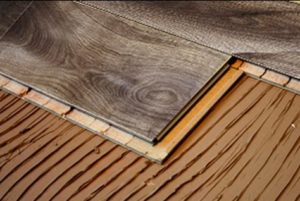

Glue mounting

The adhesive method involves gluing the boards together. It is used even when the thickness of the dies is more than 14 mm. This method is used when it is important to achieve rigidity of the base in large rooms. It is necessary to purchase a polymer-based adhesive composition. It is applied to any type of screed (cement, chipboard, plywood and others). It is not advisable to buy water-based compositions due to possible deformation of the coating. Installation is done in the following sequence:

Start laying from the longest wall. Before applying the glue, the board is laid out and the outermost one is cut off. Spacers must be installed between the first row and the wall.

Start laying from the longest wall. Before applying the glue, the board is laid out and the outermost one is cut off. Spacers must be installed between the first row and the wall.- Apply glue to the surface slightly larger than the width of the board and distribute it evenly.

- When laying, the boards are immediately joined and pressed tightly against each other. Next, they are additionally fixed with self-tapping screws.

- The next row is laid in the same way with a shift of half or a third of the length.

- The finished coating is left for several days to dry completely. Then the thresholds and baseboards are installed.

REFERENCE. Significant disadvantages of the adhesive method include the labor intensity of the work and the significant costs of high-quality glue. In addition, mistakes made will be impossible to correct in the future.

Installation using additional fasteners

This method involves the use of self-tapping screws and can be used for boards with a thickness of 20 mm or more. The fasteners are inserted into the groove at a certain angle. In this case, each plank is rigidly fixed to the base. To work, you will need finishing hardware, pneumatic pins or regular dowel-nails.

The optimal solution for this method is a construction on logs.Thermal insulation and sound insulation materials can be placed in the forming space.

ATTENTION. If the flooring is expected to have a long service life, then it is coated with a layer of varnish. At the same time, the joints are filled, and water and dirt do not penetrate into the surface.

You can do the installation of parquet boards yourself, without the help of professionals. It is important to approach this process competently, carefully study the technology and follow the recommendations.