Parquet board thickness

Reliability, attractive appearance and operating comfort of floor coverings are the determining criteria when choosing a particular material. Parquet boards have such advantages. In the recent Soviet times, parquet was classified as a prestigious type of coating. With proper surface care, such a floor can last 40–50 years, or even more. Timely surface treatment allows you to preserve the pattern and structure of the wood when used for more than half a century.

Reliability, attractive appearance and operating comfort of floor coverings are the determining criteria when choosing a particular material. Parquet boards have such advantages. In the recent Soviet times, parquet was classified as a prestigious type of coating. With proper surface care, such a floor can last 40–50 years, or even more. Timely surface treatment allows you to preserve the pattern and structure of the wood when used for more than half a century.

The content of the article

Types of parquet boards and their thickness

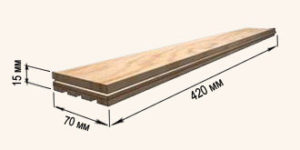

Modern material differs significantly from the small identical planks used in the last century, the installation of which was quite painstaking work. The board parameters have changed and have the following values:

- width from 14 to 20 cm;

- length from 1.8 to 2.5 m;

- thickness from 0.7 to 2.5 cm.

As in previous times, the material is distinguished by its wood species, be it pine, ash or oak. The latter has increased strength and durability. Modern technologies allow the use of various methods in the manufacture of parquet boards. Depending on this, finishing products are divided into two categories.

Solid parquet board

It is easy to understand from the name that we are talking about a solid material of the product.It is this category that includes parquet planks, which have been used since Soviet times and are still popular - the material continues to be popular. This is due to the low cost of the blanks, which can be sold in unprocessed form: for grinding the floor surface.

The thickness of such material ranges from 1.5 to 5 cm, but the main demand is for planks with a height of about 2 cm. They are conveniently laid on logs laid out in increments that correspond to the width of the pattern being created. The dimensions of such planks differ from modern parquet boards, since they have parameters close to Soviet standards. Deciduous wood is used as a raw material for the production of solid materials.

REFERENCE! The undeniable advantage of a parquet floor made from small planks is the ease of repair in case of damage to an area of any size. Having solid wood blanks in stock, damaged areas are easily restored.

A type of solid parquet is a combination of two types of wood: the top - the desired valuable material and the bottom - waterproof plywood, which serves as the base. The fibers of this base provide strength as well as stability of the product. The thickness of the wood varies from 6 mm, and the plywood sheet used varies from 10 mm. The use of a coating, which is called engineered parquet board, will allow, with a small height of the panels, to provide the required strength indicators.

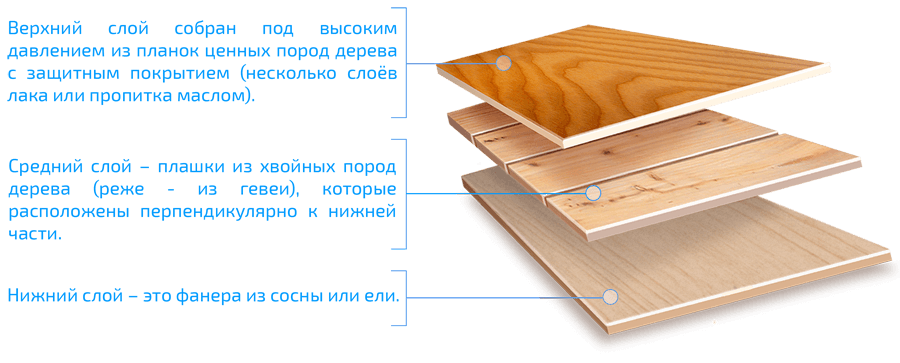

Sandwich parquet board

As an alternative to massive coating, a three-layer construction of finishing material was created in the middle of the last century. The peculiarity of the product is that the fibers of the glued layers are placed perpendicular to each other, thereby increasing the strength and durability of such panels.

The error in changing the linear dimensions of the finishing material during sudden changes in temperature and humidity is minimized. Changing the directions of the fibers reduces the pressure on the supports and cushions the coating under load. The top layer, made of wood, resembles solid wood in structure and has a fine finish. The different direction of the fibers of each layer allows, with board heights from 13 to 20 mm, to achieve the strength of massive material with a thickness of 40–50 mm, which is made to order.

REFERENCE! The structure of three-layer parquet, with a smaller thickness of the finishing material, allows you to achieve high levels of elasticity and lightens the load on the load-bearing structure of the floor.

This coating is made in the form of panels with locking locks on the side surfaces.

What does the thickness of the parquet board affect?

When choosing panels, much attention is paid to color, ornament, as well as ease of installation along the length and width of the material. An important criterion for selecting a finishing material, which affects the service life of the coating, is thickness. The number of possible surface grinding cycles during operation depends on the same indicator.

For example, when sanding floors, a layer of 1 mm is removed. The height of the top layer of parquet panels is 7 mm, allowing this treatment to be performed only 6 times. The scraping of solid wood floors is carried out to a depth of no more than 30% of the size of the planks. If the overall value of this parameter is less than 10 mm, grinding is not recommended. In addition, thickness affects the rigidity and thermal conductivity of the coating. The greater the height of the product, the warmer the floor will be.

IMPORTANT! When processed by a scraping machine, the appearance of the finishing material improves, but at the same time it loses strength.

The cost of parquet planks made from solid wood directly depends on the thickness of the product. In sandwich panels, the determining criterion for price will be the quality and manufacturability of the coating.

What thickness to choose a parquet board depending on the room

For residential premises, a material with a small height of 13–16 mm is used, since the loads here are small and the strength requirements are low. In rooms equipped with heated floors, boards with a minimum thickness are used. This is due to the low thermal conductivity of wood coating.

ATTENTION! If there are other types of coatings in the apartment, the size of the finishing material is selected in such a way that when joining (for example, with tiles), the height difference is minimal!

If there is increased load on the floor, for example, in a hallway or office, lay parquet boards 16–20 mm thick. When installing floors in public places, use products with a height of more than 20 mm.

If the finishing material is laid on logs, then the thickness of the board should be at least 20 mm for the rigidity of the created coating.

Taking into account the features of choosing parquet, select the desired color and pattern of the product. After this, cover the floor with a board and enjoy the result.