The difference between engineered wood and parquet boards

Currently, you can find several types of parquet flooring made from natural materials. However, each of them has properties that are different from each other. In this article we will look at some of them, and also try to decide which type is better to choose in a given situation.

The content of the article

Main features of parquet boards

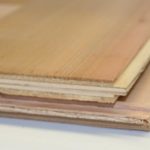

The product itself, unlike ordinary parquet, consists of several layers. This helps to significantly increase the service life of the structure, as well as provide sound insulation to the room. In addition, the purchased material is already ready for installation, that is, it does not require further processing. Below is a list with brief characteristics:

The first layer provides stability and even distribution of stress between other parts of the surface.

The first layer provides stability and even distribution of stress between other parts of the surface.- The next element is considered the main one. Thanks to it, a uniform coating is guaranteed, which does not require any sanding or adjustment.

- The decorative range is made using certain wood, for example, it can be the bark of oak, maple, cherry or ash.

- The final component is a protective top coating. It most often includes such products as special varnish, wax, oil-wax mixture and various types of oil.

Thus, with the help of the described layers we can talk about such features as water resistance, protection from the sun, scratches and other damage.

Main features of engineering board

The presented version of the raw material is also manufactured using a multilayer principle. However, the layers are different, due to which its advantages are different. For example, this item does not respond to sudden changes in temperature and humidity, since the wood fibers of the structure are located in the opposite direction.

ATTENTION. The structure can be repaired in the future, since the resource itself allows itself to be polished and scraped.

So, the provided layers are:

The main element is premium grade birch plywood. It includes more than 6 layers, the number can reach up to 8.

The main element is premium grade birch plywood. It includes more than 6 layers, the number can reach up to 8.- The decorative layer gives the coating the most neat appearance.

- The protective layer is no different from the previous version: it is also equipped with glue, oil and other processing agents.

In addition, it is equipped with stiffening ribs, which allows it to be even more stable. As for the actual installation, it is better to do this not on plywood, but immediately on the screed. This method can significantly reduce costs. However, it is important to remember that no screws will be required to install the object.

What is the difference between parquet board and engineered board?

So, in conclusion, it is possible to draw conclusions that may help when purchasing this or that product. The difference between parquet and engineered material is as follows:

- The maximum size of the first of them is several indicators smaller than the second, namely length: 2.2 meters and 2.4, respectively.

- Next thing you can notice is the difference in design. When using a parquet product, the user can rely exclusively on the classic version, but with a variety of treatments. The other has a “herringbone” or “square” surface.

- An important difference is the installation method. Although using an engineered board may require a glue-free method, as with any other item, it is possible to use glue. Therefore, with parquet plywood, only the floating option is needed.

- The service life also varies. The first of them is usually used for about 20 years. Speaking about the second, it is worth mentioning a much longer period of time - up to 40 years.

- Both have a water heating system. It is worth adding an infrared heating method to the parquet element.

- If you decide to restore the structure, then simple interaction can only be expected with the first mentioned product. Due to the addition of glue, the second one will be difficult to work with.

- Perhaps the last thing to mention is the difference in cost. For engineering, you will have to pay more than three thousand rubles.