Parquet production

Parquet is one of the popular and sought-after floor coverings. It is made by manufacturers in Russia and other countries from solid wood using special equipment. The production of this material is a complex and responsible process, on which the quality characteristics of the coating depend.

Parquet is one of the popular and sought-after floor coverings. It is made by manufacturers in Russia and other countries from solid wood using special equipment. The production of this material is a complex and responsible process, on which the quality characteristics of the coating depend.

The content of the article

Parquet production

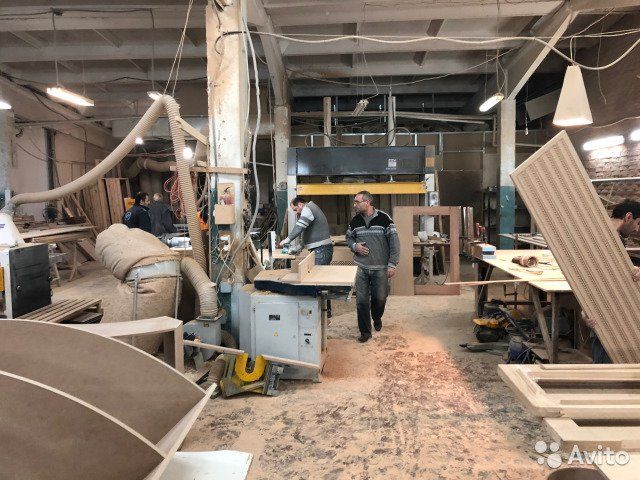

To produce parquet you must have special equipment. This includes sawing machines, drying units, saw sharpening mechanisms and a gluing press. The production of parquet is based on the use of special devices that perform each component with precision. These can be planing, milling and end-cutting machines. All major fixtures should be located in close proximity to each other.

REFERENCE! If the workshop is small, then some of the actions can be carried out in other utility rooms. In most cases, preparatory work is carried out in an open area under a canopy.

In general, the parquet business is popular among investors and entrepreneurs. The profitability of the business is, according to various estimates, about 15%. When selecting equipment, it is necessary to take into account the type of product being manufactured. Economy class products require much less financial investment, while the production of luxury products will require the additional purchase of additional mechanisms.

What is it made from?

Only the most valuable wood species are used in the production of the coating.Traditional materials are oak, walnut, birch, maple, ash and beech. Olive, merbau, cherry, chocolate tree and others are considered exotic. Exclusive breeds have improved performance indicators. Thus, they are much more resistant to moisture and temperature changes. During the manufacturing process it is necessary to combine different types of wood. The starting material is small bars 10 mm thick.

Only the most valuable wood species are used in the production of the coating.Traditional materials are oak, walnut, birch, maple, ash and beech. Olive, merbau, cherry, chocolate tree and others are considered exotic. Exclusive breeds have improved performance indicators. Thus, they are much more resistant to moisture and temperature changes. During the manufacturing process it is necessary to combine different types of wood. The starting material is small bars 10 mm thick.

IMPORTANT! Before making, you should make sure that the wood is well dried. Otherwise, the finished floor covering may warp. Humidity according to GOST should be no more than 3-9%.

Production technology

The parquet production technology of each manufacturer is approximately identical. The only differences are in the sequence of steps and some processing methods. In addition, the quality of the final product depends on the manufacturer’s attitude to the production process and control at each stage of work. Let's consider the main stages of coating production:

The parquet production technology of each manufacturer is approximately identical. The only differences are in the sequence of steps and some processing methods. In addition, the quality of the final product depends on the manufacturer’s attitude to the production process and control at each stage of work. Let's consider the main stages of coating production:

- Preparatory stage. While the wood is in a warehouse or storage point, it is important to carefully prepare it for further work. It must be checked for mechanical damage and other defects. Defective raw materials are not allowed into work.

- Drying sorted products. In special drying compartments, wood species are kept under high temperatures for a couple of months. At this stage, heat treatment of the material occurs.

- Sawing timber. During this stage, the coating is given the required configuration.

- Some parts are glued together using a special press.

- Coating sanded products with varnish or oil and sending them to the finished goods warehouse.

- After finishing coating, the raw materials are dried in a chamber under the influence of UV radiation.

REFERENCE! Thanks to heat treatment, the wood is strong, dense and resistant to various types of mechanical stress.

Advantages and disadvantages of parquet boards

Among the few disadvantages of the coating, it can be noted that the product must be protected from exposure to high temperatures, moisture and chemical compounds. In addition, the pattern of the canvas is one-way. The listed disadvantages are compensated by the versatility of this product and its practicality. The significant advantages of this coating include the following:

Among the few disadvantages of the coating, it can be noted that the product must be protected from exposure to high temperatures, moisture and chemical compounds. In addition, the pattern of the canvas is one-way. The listed disadvantages are compensated by the versatility of this product and its practicality. The significant advantages of this coating include the following:

- •Variety of color shades

- Good wear resistance and long service life

- Suitable for finishing rooms in a classic style.

- The product is sold ready-made and can be installed immediately after purchase.

- Simple and convenient installation due to the presence of a convenient lock

- Resistance to mechanical damage.

- The material can be laid on a heated floor, having previously installed waterproofing.

- It is convenient to adjust the length of the strips to the dimensions of the room by simply cutting off the excess part.

ATTENTION! Parquet boards are an environmentally friendly product that is safe for human health.

High-quality parquet must have the necessary quality certificates. With the right choice of material and flooring, the coating will serve its owner for many years.