Insulation of floors under linoleum on a concrete floor

The concrete floor itself is cold. The linoleum that is laid on it should be insulated. There are a number of special materials and methods for this purpose.

The content of the article

What type of insulation to choose for linoleum on a concrete floor

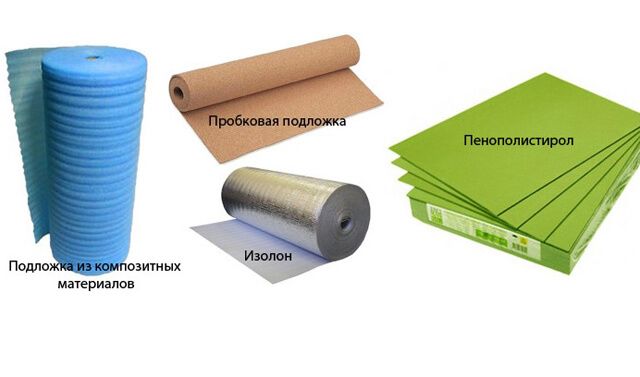

What to put under linoleum on a concrete floor? When choosing a material, you must rely on the type of linoleum, the characteristics of the insulation and material capabilities. But you also need to choose a substrate. It is located between the canvas and the insulation. The modern market offers the following types of substrates:

What to put under linoleum on a concrete floor? When choosing a material, you must rely on the type of linoleum, the characteristics of the insulation and material capabilities. But you also need to choose a substrate. It is located between the canvas and the insulation. The modern market offers the following types of substrates:

- Rolled cork (this is crushed cork oak bark, compressed. It is elastic, protects against fungus and mold, and has good thermal insulation).

- Jute (natural jute fibers are pierced with a needle and rolled on rollers at high temperature0. It is fire-resistant and resistant to fungus formation).

- Linen (natural linen is pierced with a double needle and then impregnated. It is fire resistant and protects against mold formation).

The following insulation materials are suitable for concrete floors:

- penoplex (has a long service life and durability. It is easy to install. Due to its small thickness, it can be cut with a simple knife);

- Isolon (another name: polyethylene foam. It has excellent qualities, including: waterproofing, environmental friendliness, thermal insulation, wear resistance and vapor barrier.Very popular due to its affordable price).

Insulation of a floor under linoleum on a concrete floor can be done as follows. Thanks to modern technologies, “Warm Floor” systems were released. They warm up the room well. Their installation must be carried out by a specialist familiar with safety precautions. The cost of the system is much higher than conventional materials, but the result exceeds all expectations. Among the most popular:

- Infrared (film. Takes up little space. Maintains a comfortable temperature in the room).

- Water.

- Cable.

- Thermal mats.

What tools will you need?

For high-quality assembly of materials, it is necessary to prepare the following tools:

For high-quality assembly of materials, it is necessary to prepare the following tools:

- substrate;

- insulation;

- Fiberboard, plywood;

- construction tape;

- polyethylene;

- screwdriver;

- jigsaw;

- knife;

- scissors;

- glue;

- self-tapping screws

How to put the material correctly

To carry out quality work, you need to take the following actions:

To carry out quality work, you need to take the following actions:

- It is necessary to inspect, level and clean the floor.

- Install the backing (the height is selected so that the door opens and closes freely).

- Isolon or penoplex is laid (all joints are connected with tape).

- Sheets of plywood or fiberboard are laid (attached with self-tapping screws. The fiberboard must be waterproofed. Therefore, a plastic film is laid under it, and the material is primed. Without these measures, the fiberboard may swell).

- Linoleum is installed on top.

Important! To prevent water from getting inside the canvas, select rectangular-shaped plinths.