Installation of warm electric floor under linoleum

Heated floors are an excellent alternative to central heating: they can be turned on and off as needed at any time of the year. There are types: heated by water and electricity. Let's consider the advantages, disadvantages and installation of electric heated floors under linoleum.

Heated floors are an excellent alternative to central heating: they can be turned on and off as needed at any time of the year. There are types: heated by water and electricity. Let's consider the advantages, disadvantages and installation of electric heated floors under linoleum.

The content of the article

Advantages and disadvantages of electric heated floors

To make it easier to choose in favor or against the installation of an electric heated floor, we will consider the pros and cons of such heating.

Advantages:

- its installation does not require special skills; the ease of installation allows you to do the work yourself;

- it is installed both throughout the room and in some places (in the bathroom, balcony, corridor);

- the ability to install in high-rise buildings where the use of water systems is prohibited;

- 2 types of heater (infrared film or cable);

- thanks to the presence of a thermostat, you can adjust the temperature mode and automatically turn off and on;

- can be installed both in a residential area and in an office;

- can be laid under any covering (laminate, porcelain tiles, tiles, linoleum and others);

- long service life with careful and proper handling;

- uniform heating of the surface;

- quick determination of the cause of the malfunction;

- safe due to low heating temperature;

- there is no need to install additional equipment (for example, a gas boiler for heating water).

Flaws:

- high operating cost when using a heating cable;

- danger of electric shock (especially in damp areas);

- the cable creates an electromagnetic field harmful to humans;

- coating made of wood or linoleum can be deformed under the influence of high temperatures;

- when laying the cable, the height of the room can be significantly reduced;

- when used as the main source of heating (especially over a large area), high-power electrical wiring will be required.

What to choose: cable or infrared film

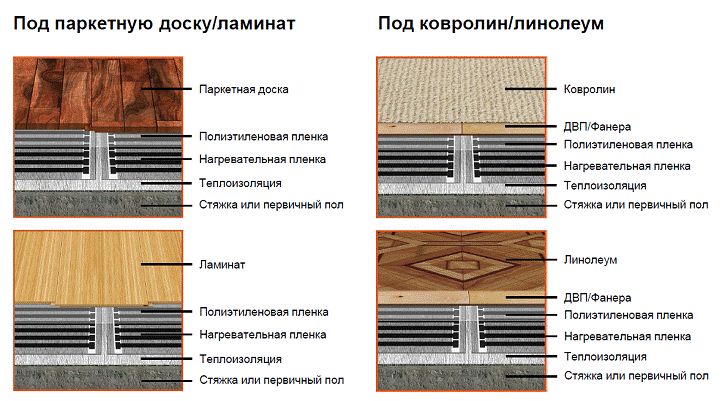

There are 2 types of heating systems: cable and infrared film. The advantage of the first is its affordable price. The disadvantages include the complexity of installation and the possibility of overheating - the temperature range is no more than 25 degrees. In addition, due to the thickness of the system (screed, thermal insulation, vapor barrier), the height of the room changes significantly.

Infrared film - is a complex system of a thin (less than 1 mm thick) graphite heating element in a film. It is connected to electricity using conductors. It is placed on a leveled base, and then the covering is laid.

Advantages:

- low running costs for electricity;

- heating with infrared rays does not require a screed;

- temperature regulation using the included thermostat (it is installed in a niche in the wall);

- no overheating;

- a thin layer does not change the height of the room;

- can be installed after the renovation of the premises is completed.

The disadvantages include the rather high cost and high requirements for the floor - it must be perfectly flat. Even a small difference in height can damage the film.

REFERENCE! Many experts consider infrared film to be the most suitable room heating system.

Installation of infrared heated floor

The first step during installation is to install a flat floor, and then lay the polystyrene foam backing (the foil layer should be placed on top to reflect heat).

ATTENTION! For floors between rooms, the substrate installed should not be thicker than 4 mm. The joints are connected with tape.

Further:

- the film is laid out on the open floor and the required size is cut in specially marked places;

- the film is fixed;

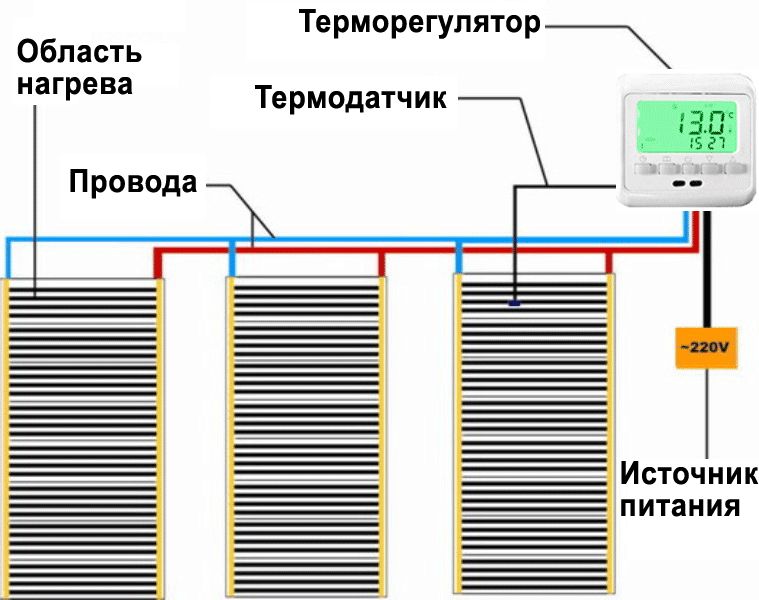

- the wires are connected to the strips with copper terminals; it is advisable to place them closer to the baseboard;

- a thermostat is installed in the wall;

- wires are connected to the control panel;

- temperature sensors are installed;

- All wires are connected to the control unit;

- work is tested to check the quality of the connection.

If the heated floor is working properly, you can begin laying linoleum.

Features of working with the cable system

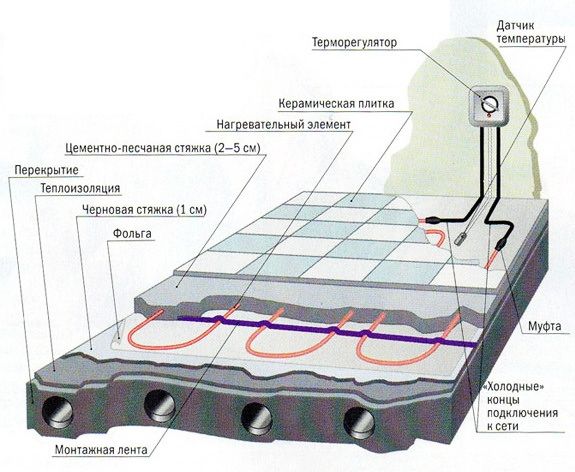

Before installing the cable system, a cable with a power of up to 150 W/m2 is selected and a layout plan is drawn. Preparatory work is being carried out to clean the floor from debris, leveling and priming the surface. Further:

- thermal insulation material is laid (expanded polystyrene boards or rolled polyethylene foam with a reflective layer);

- the mounting grid (mounting slats) is laid;

- the cable is laid according to plan;

- Thermal sensors are installed between 2 turns of the cable, the wires are passed through a special corrugated pipe to protect them from contact with the cable and screed;

- sensors are connected to a wall-mounted thermostat and electricity;

- the serviceability of the cable floor is tested;

- The concrete screed is poured and leveled (screed thickness is more than 9 cm).

IMPORTANT! It is recommended to make the screed thickness more than 9 cm to prevent overheating and damage to the coating.

2 weeks after the surface has dried, linoleum is laid on top of the screed on the heated floor that is turned off. It is advisable not to use this system as the main source of heat due to linoleum’s intolerance to high temperatures.

Laying linoleum on a warm floor

Before laying, the rolls must be left in the room for 5–6 hours, otherwise the linoleum may become deformed. Further actions:

- surface preparation (differences, irregularities and joints are puttied, then the surface is primed) - for a rigid base, chipboard or plywood is taken;

- linoleum is rolled out over the floor surface, cut off at a distance of 0.5 cm from the wall and allowed to straighten for 24 hours;

- When laying on a concrete floor, it must be glued with heat-resistant linoleum glue.

ATTENTION! On the back of the linoleum there is a marking that allows you to determine the possibility of using a heated floor (the marking guarantees the quality and safety of operation at high temperatures).

The best is considered to be linoleum made from natural material, which is resistant to high temperature and wear. When installing synthetic coatings, you need to lay a layer of wood-fiber boards.