Linoleum production

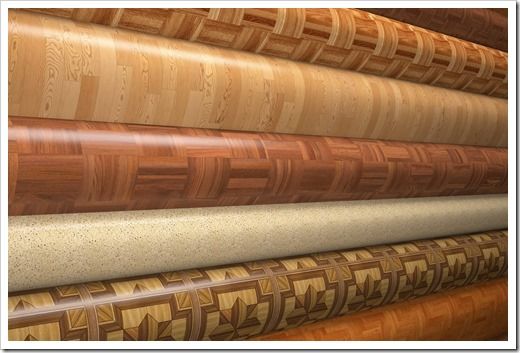

When choosing a floor covering for any room, most people choose linoleum - this material is inexpensive, quite easy to install and subsequently maintain. A huge selection of colors and patterns makes it possible to choose a floor covering that can fit into any room design. When choosing, it is necessary to take into account the expected load on the coating, as well as its service life.

When choosing a floor covering for any room, most people choose linoleum - this material is inexpensive, quite easy to install and subsequently maintain. A huge selection of colors and patterns makes it possible to choose a floor covering that can fit into any room design. When choosing, it is necessary to take into account the expected load on the coating, as well as its service life.

The content of the article

Production process

Today there are several manufacturing options:

- Extrusion.

- Roller-calender.

- Missing.

The last method consists of applying molten plastic to a fabric base in one layer. The solution already contains various additives and plasticizers. After this, the product is sent under the press. At this point the manufacturing stage is completed.

The second method is to mix PVC with mineral additives, multi-colored pigments and cork flour. Then this composition is applied to a coarse-mesh base (a fabric base is most often used), all layers are processed with rollers. The finished linoleum is coated with acrylic and dried.

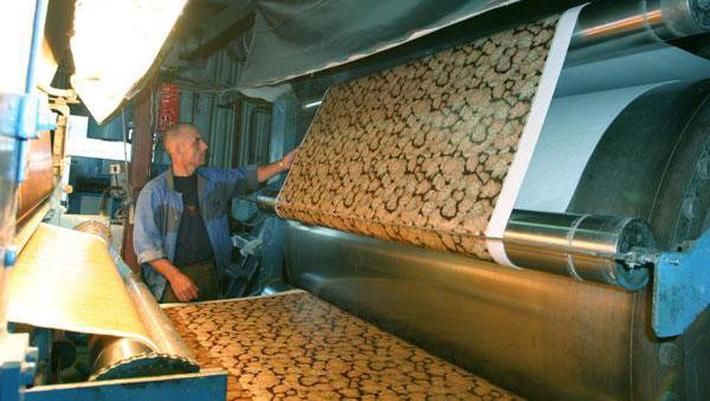

The technology for producing material using extrusion consists of the following sequence:

- Mixing the polyvinyl chloride composition, adding the required components.

- Making the bottom layer. Selecting a fabric base or making a foam backing.

- Fastening all layers of the future product in an extruder is a special machine that is used to plasticize the material and give it the appropriate structure.

- Smoothing the material and final fixing the shape in the calender.

- Artificial shrinkage in a thermal chamber and further cooling.

- Cutting, unwinding the product into rolls and packaging.

Manufacturing equipment significantly affects the quality of the future product. Most often, German machines are used, which make it possible to automate the linoleum manufacturing process from the laying of raw materials to the production of finished products, but the cost of the material is quite high.

Mixing rollers and an ironing calender are also used. The former are required to create a plasticizer and to heat the composition for further processing on extruders and special machines.

The rollers have several heating elements - a special liquid or electricity is used as a heat carrier.

The rollers can also be equipped with various options:

- speed regulation;

- power sensors;

- saving technological production in the memory of the machine;

- electronic control panel.

Reference! The calender works simultaneously with the press. This equipment is required for gluing the top surface and base of linoleum. In addition, it stretches the coating and can also give the desired shape.

Which factories produce linoleum?

Among the many different manufacturers, the most popular are the following:

- Forbo is a manufacturer from Switzerland. Environmental friendliness is the main advantage of the manufacturer. Forbo produces marmoleum linoleum using natural materials.This approach gives the products a long service life (at least 35 years), increased heat capacity and antibacterial properties.

- Tarkett is a company with an ideal reputation. All linoleum production is focused on impeccable aesthetics and safety of the finished product. All rolls are produced using multi-layer technology. Almost all collections contain added silver, which prevents the penetration of dust.

- Armstrong - linoleum is characterized by increased wear resistance, strength, heat and sound insulation. All products are manufactured using modern European equipment. Armstrong linoleum can be purchased in different variations: from household to industrial use.

- All products from Grabo are distinguished by the use of fiberglass in linoleum. This increases strength and increases service life. The design solutions for the collections of the manufacturing plant are quite unusual. Most often, the classics are visible here - the flooring is made of ceramics, parquet, laminate. The company produces a special line for the kitchen, living room, and children's room.

- Gerflor is a manufacturing company from France. The brand is distinguished by a scientific approach to the manufacture of its products. All products are developed taking into account the latest technological advances in the industry.

- All flooring collections under this brand are characterized by a long service life and a specially designed protective layer that prevents the surface from fading, abrasion and decomposition.

Attention! Linoleum from these manufacturing plants can be used for any type of premises; it can perfectly cope with increased loads, has all certificates and is completely environmentally friendly.

List of factories in Russia

When choosing linoleum, many consumers most often pay attention to the products of foreign manufacturers. It is believed that this material is of better quality than Russian-made linoleum and, accordingly, has a higher price. But taking into account current trends in the development of the domestic market, this is completely wrong. Here is a list of leading companies in this field:

- Enterprise "TarkettRus".

- Factory "Techno Tex".

- Company "Yenisei"

- "Uralspetstrans"

- Shchelkinsky linoleum.

All described varieties of linoleum are suitable for laying under a heated floor. If you choose the most economical option, then it is best to purchase polyvinyl chloride products. Do not forget that natural linoleum is the most expensive, but this way you can get the most durable floor covering that will perfectly maintain its performance qualities.